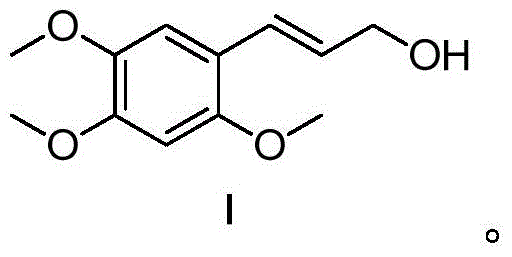

α-Asarocyl alcohol and its preparation method and application

A technology of asaranol and fatty alcohol, applied in the field of preparation of alpha-asaranol, can solve problems such as cognitive dysfunction, severe allergic reaction and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

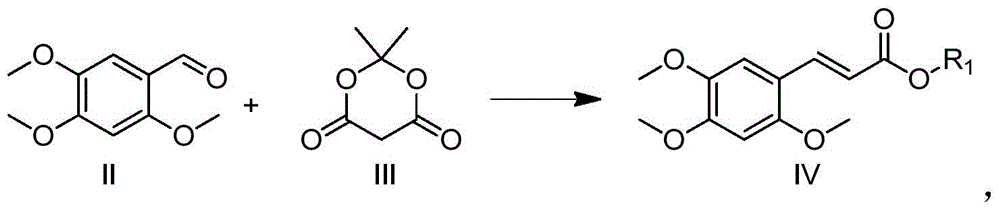

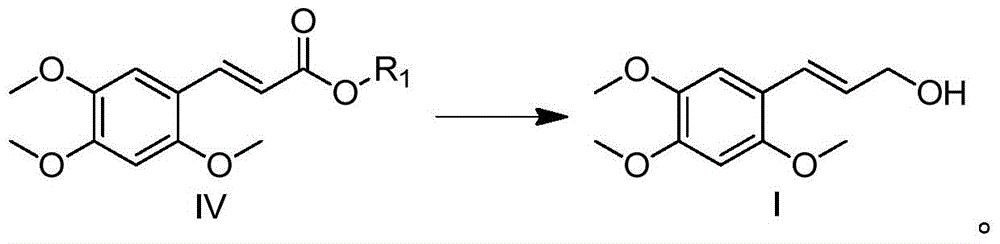

Method used

Image

Examples

Embodiment 1

[0021] Preparation of Methyl 2,4,5-Trimethoxycinnamate

[0022] A 3L three-necked flask with a thermometer and a condenser tube was added with 195.5g (1.35mol) of McFarlandic acid (1.35mol), methanol (50mL) and toluene (750mL), heated to reflux at 110°C for 4 hours, cooled to room temperature, and then added with 2,4 , 196.2g (1.0mol) of 5-trimethoxybenzaldehyde, 134.5g (1.7mol) of pyridine, and 14.5g (0.17mol) of piperidine, heated to reflux for 18 hours, concentrated under reduced pressure, then added ethyl acetate (200mL), Water (200mL), extracted and separated 3 times, combined the organic phases, concentrated under reduced pressure, added ethanol (1000mL), refrigerated overnight in the refrigerator, after the precipitation was precipitated, filtered with suction, washed 3 times with 500mL of ice ethanol to obtain a light yellow solid 166.3 g, 66% yield.

[0023] m / z=[M+1]253.1086

[0024] 1 H NMR (600MHz, cdcl3) δ7.97(d, J=16.1Hz, 1H), 7.01(s, 1H), 6.50(s, 1H), 6.38(d,...

Embodiment 2

[0027] Preparation of ethyl 2,4,5-trimethoxycinnamate

[0028] In a 250mL three-neck flask with a thermometer and a condenser tube, add 20.2g (0.14mol) of McFarlandic acid (0.14mol), ethanol (10mL), and toluene (150mL) respectively, heat and reflux at 110°C for 4 hours, cool to room temperature, and then add 2,4 , 19.6g (0.1mol) of 5-trimethoxybenzaldehyde, 13.5g (0.17mol) of pyridine, and 1.5g (0.017mol) of piperidine, heated to reflux for 18 hours, concentrated under reduced pressure, then added ethyl acetate (50mL), Water (50mL), extracted and separated 3 times, combined the organic phases, concentrated under reduced pressure, added ethanol (150mL), refrigerated overnight, after the precipitate was precipitated, filtered with suction, washed 3 times with 100mL ice-ethanol to obtain a light yellow solid 16.0 g, 60% yield.

Embodiment 3

[0030] Preparation of Propyl 2,4,5-Trimethoxycinnamate

[0031] In a 250mL three-neck flask with a thermometer and a condenser tube, add 10.1g (70mmol) of McBurney's acid, propanol (8mL), and toluene (80mL) respectively, heat and reflux at 110°C for 4 hours, cool to room temperature, and then add 2,4 , 5-trimethoxybenzaldehyde 9.8g (50mmol), pyridine 6.7g (85mmol), piperidine 0.75g (8.5mmol), heated to reflux for 18 hours, concentrated under reduced pressure, added ethyl acetate (20mL), water ( 30mL), extracted and separated 3 times, combined the organic phases, concentrated under reduced pressure, added ethanol (80mL), refrigerated overnight in the refrigerator, after the precipitation was precipitated, filtered with suction, washed 3 times with 50mL of ice ethanol, and obtained 7.7g of light yellow solid , yield 55%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com