A kind of preparation method of light-weight broadband wave-absorbing material

A technology of wave absorbing material and bandwidth, applied in the field of functional materials, to achieve the effect of obvious absorption effect, broad application prospect and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

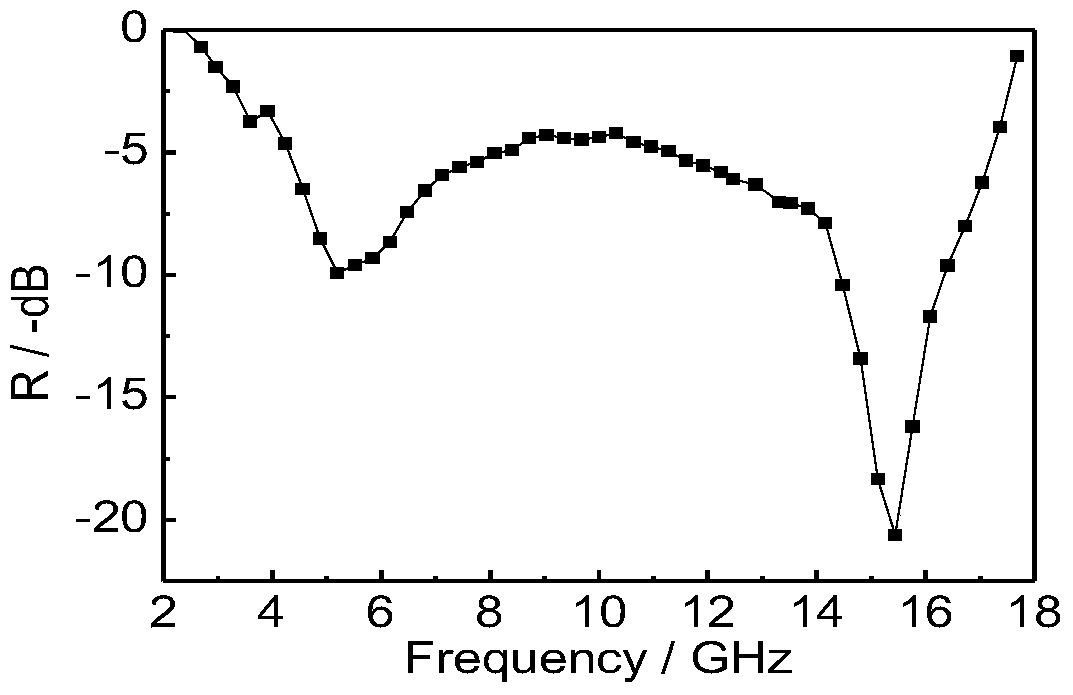

Embodiment 1

[0022] Step 1: Accurately weigh 85g of the mixture of conductive carbon black and carbonyl iron, 7g of acrylic resin, 8g of silane coupling agent, and 100g of absolute ethanol; dissolve the acrylic resin in absolute ethanol, and stir until it dissolves into a transparent homogeneous solution;

[0023] Step 2: Add conductive carbon black and silane coupling agent to the above-mentioned adhesive glue, mechanically stir and sonicate for 30 minutes to prepare absorbent glue;

[0024] Step 3: Immerse soft polyurethane with a thickness of 6mm in the above glue, pull the filtrate, then dip again, repeat 4 times, finally drain the excess glue, and dry it in a vacuum oven at 40°C ;

[0025] Step 4: Process the dried flexible polyurethane-based foam absorbing material according to the size specified in "GJB2038-94" to obtain the finished product.

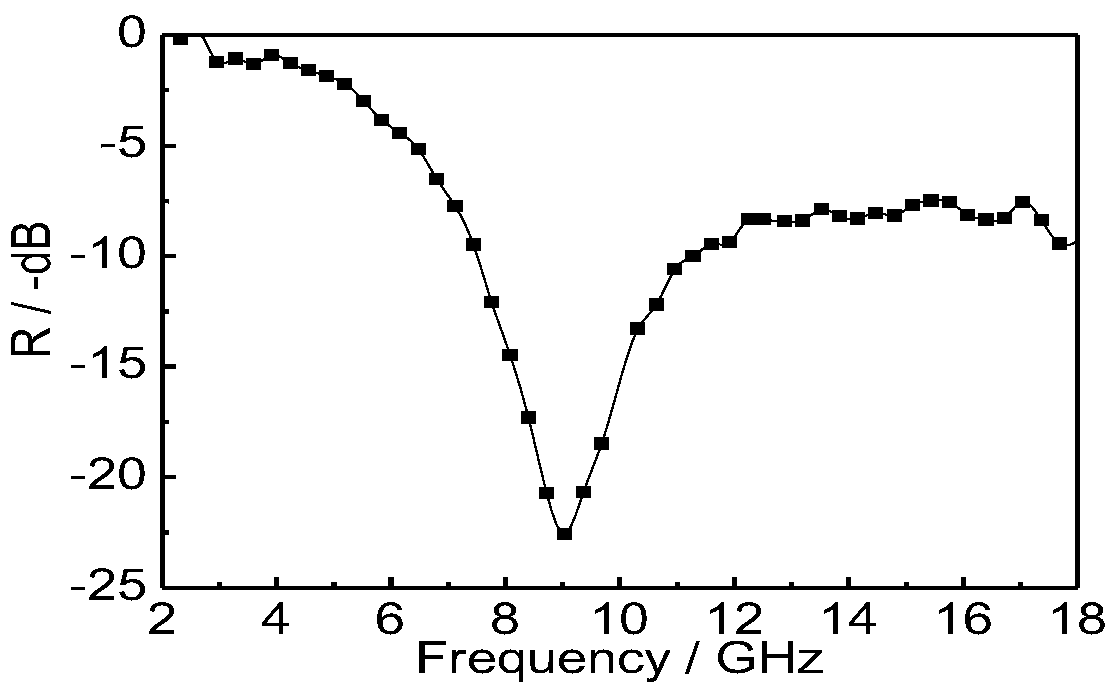

Embodiment 2

[0027] Step 1: Accurately weigh 75g of the mixture of conductive carbon black and carbonyl iron, 21g of acrylic resin, 4g of silane coupling agent, and 100g of absolute ethanol; dissolve the acrylic resin in absolute ethanol, and stir until it dissolves into a transparent homogeneous solution;

[0028] Step 2: Add conductive carbon black and silane coupling agent to the above-mentioned adhesive glue, stir mechanically and ultrasonically for 45 minutes to prepare absorbent glue;

[0029] Step 3: Immerse soft polyurethane with a thickness of 3mm in the above glue, pull the filtrate, then dip again, repeat 3 times, finally drain the excess glue, and dry in a vacuum oven at 40°C ;

[0030] Step 4: Process the dried flexible polyurethane-based foam absorbing material according to the size specified in "GJB2038-94" to obtain the finished product.

[0031] Depend on image 3 It can be seen that the light-weight broadband wave-absorbing material prepared in this example has good wav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| absorption bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com