Method for prefabricating and constructing separated rail structure

A construction method and separate technology, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of low construction efficiency, high maintenance cost, long cycle, etc., achieve efficiency improvement, convenient maintenance and replacement, and solve construction costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

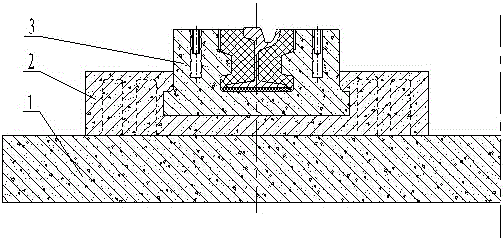

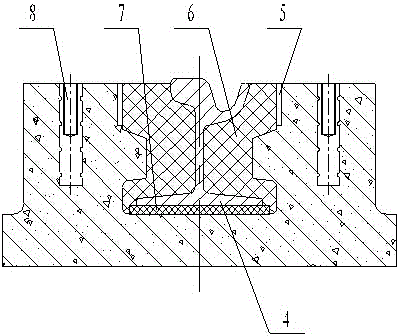

[0037] like figure 1 , 2 As shown, a separate track structure prefabrication and construction method, the separate track structure includes a separate track support groove and a factory prefabricated track system, through the prefabrication of the separate track structure, the separation of the function of the support groove, the track plate, and the track The system is factory made.

[0038] The prefabrication method of the separated track structure is as follows:

[0039] Step 1: Material preparation: Prepare the materials used in the separated track system, including steel rail 4, prefabricated rail support groove 3, under-rail pad 7, polymer casting material 6, Concrete track slab 1, cast-in-place concrete connection layer 2, steel plate 5 and conduit 8 ; The preparation of the material includes:

[0040] 1. Rail blasting, rust and dust removal;

[0041] 2. The prefabricated rail bearing groove is produced by modular flow;

[0042] 3. The backing plate under the rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com