Steel pipe concrete composite system of building and masonry construction method thereof

A technology of concrete filled steel tube and concrete, which is applied in the direction of buildings, building components, building materials, etc., to achieve the effect of improving seismic performance, small weight and saving consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

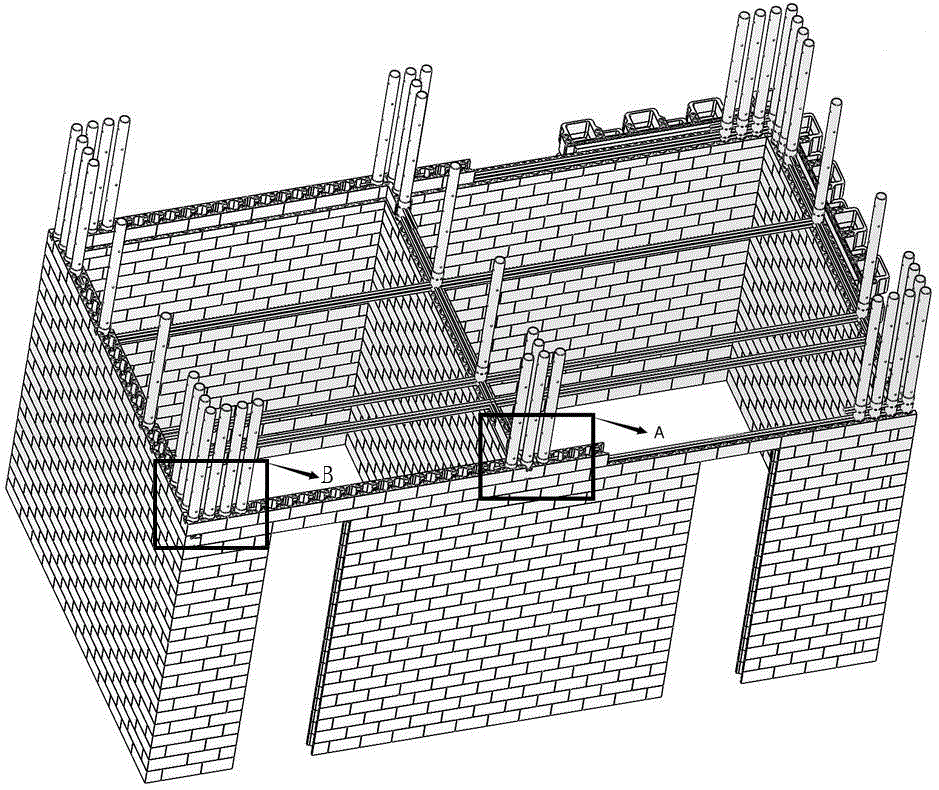

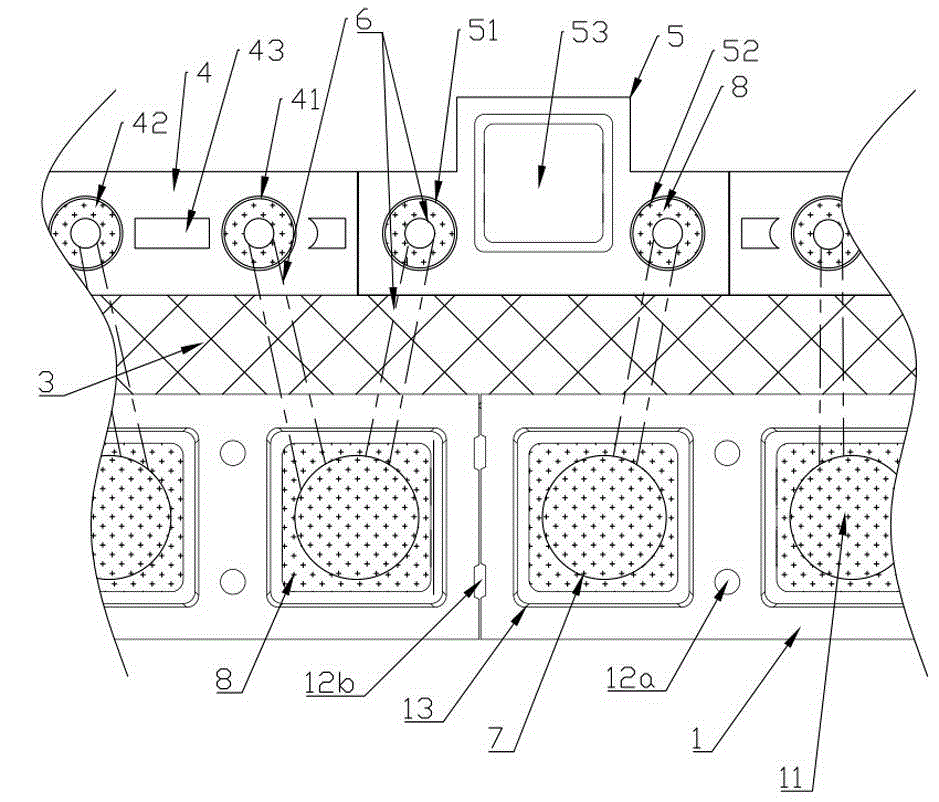

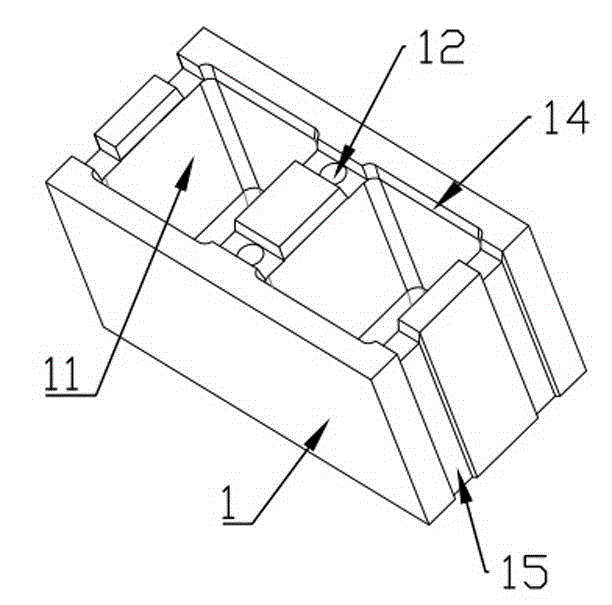

[0055] In the following, the specific implementation manners of the present invention will be further described in detail in conjunction with the accompanying drawings of the embodiments, so as to make the technical solution of the present invention easier to understand and grasp.

[0056] Aiming at the deficiencies of traditional building materials and masonry methods, the present invention proposes a new architectural steel pipe concrete composite system and its masonry method, which solves the problems of seismic strength of formed buildings, convenience of masonry, light materials, transportation and construction costs The optimized comprehensive architectural problem is a pioneering and innovative solution.

[0057] Generally speaking, the technical scheme of the present invention shows that the structural features of the steel pipe concrete composite system of the building are from the inside to the outside the composite multi-layer wall of the inner wall, insulation boar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap