Method for partial recovery of residual coal from wide coal pillar

A large coal pillar and residual coal technology, applied in the field of partial recovery of large coal pillar residual coal, can solve the problems of high stress concentration factor, complex stress environment, difficulty in ensuring large coal pillar recovery, etc., and achieve the effect of preventing the influx of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

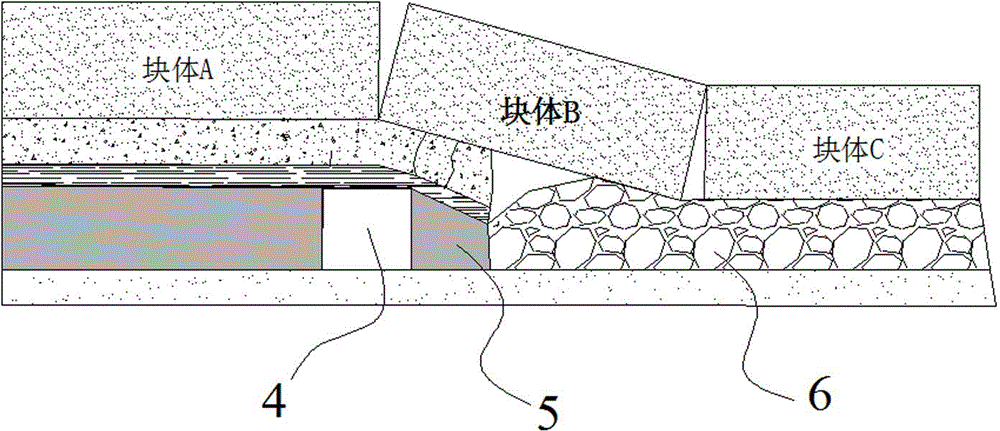

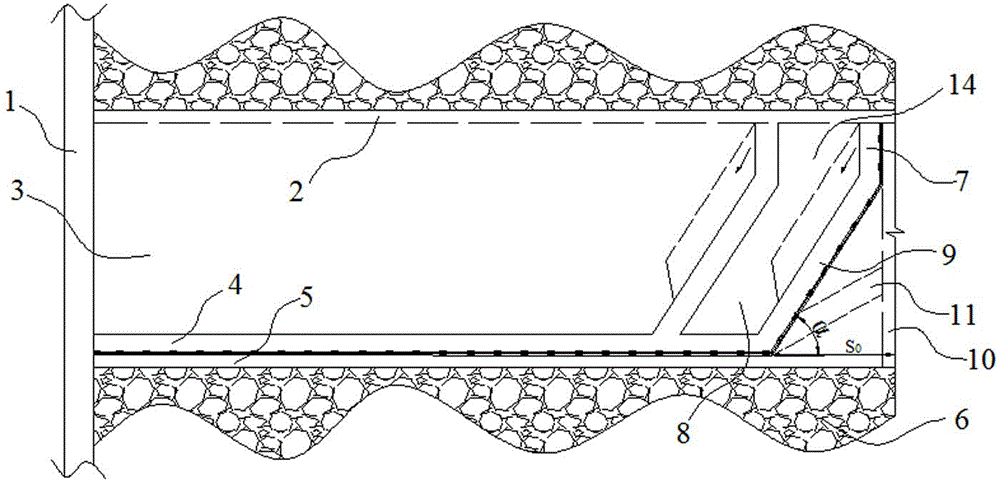

[0029] Such as figure 1 , 2 As shown, after the roof of the goaf 6 on both sides of the large coal pillar 3 has subsided and stabilized, the boundary of the large coal pillar 3 is under the protection of the key block B of the old top, and the mining quasi-roadway 4 is excavated near the boundary of the goaf. The surrounding rock has low stress and is easy to stabilize.

[0030] Residual coal mining of large coal pillars:

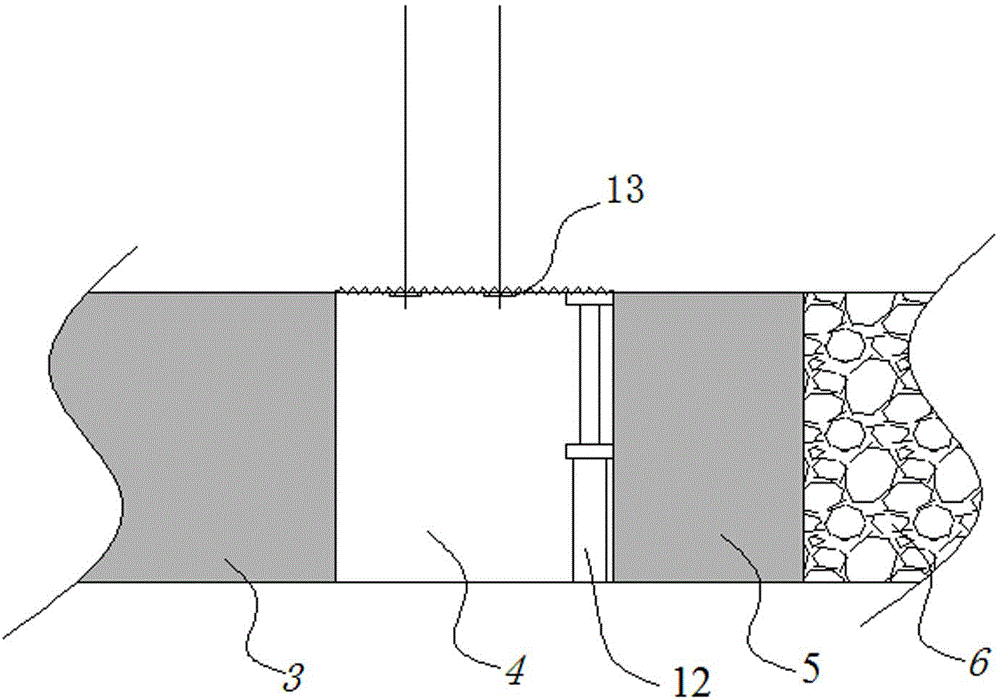

[0031] (1) Starting from section centralized roadway 1, excavate a mining roadway 4 with a width of about 3 m in the coal body on the side of the large coal pillar 3, and leave a thin coal wall 5 on the side of the mining roadway 4 close to the goaf 6.

[0032] (2) Immediately after excavation of the mining roadway 4, a single hydraulic prop 12 is installed on one side of the thin coal wall 5 to cooperate with support structures such as anchors, beams, nets, and cables to jointly support and support the roof to control the roof and the thin coal wall 5 S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com