Double-butterfly-shaped cooperation flow distribution pump driven by linear resonance motors

A motor-driven, flow distribution pump technology, applied in the field of hydraulic pumps, can solve the problems of limited dynamic adjustment capacity of system flow and pressure, internal transmission links and friction pairs of plunger pumps, and cannot meet the high dynamic requirements of the pump control system, etc., to achieve The effect of improving the overall efficiency, good processing and assembly process, and small friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described below with reference to the drawings. Elements and features described in one drawing or one embodiment of the present invention may be combined with elements and features shown in one or more other drawings or embodiments. It should be noted that representation and description of components and processes that are not related to the present invention and known to those of ordinary skill in the art are omitted from the drawings and descriptions for the purpose of clarity.

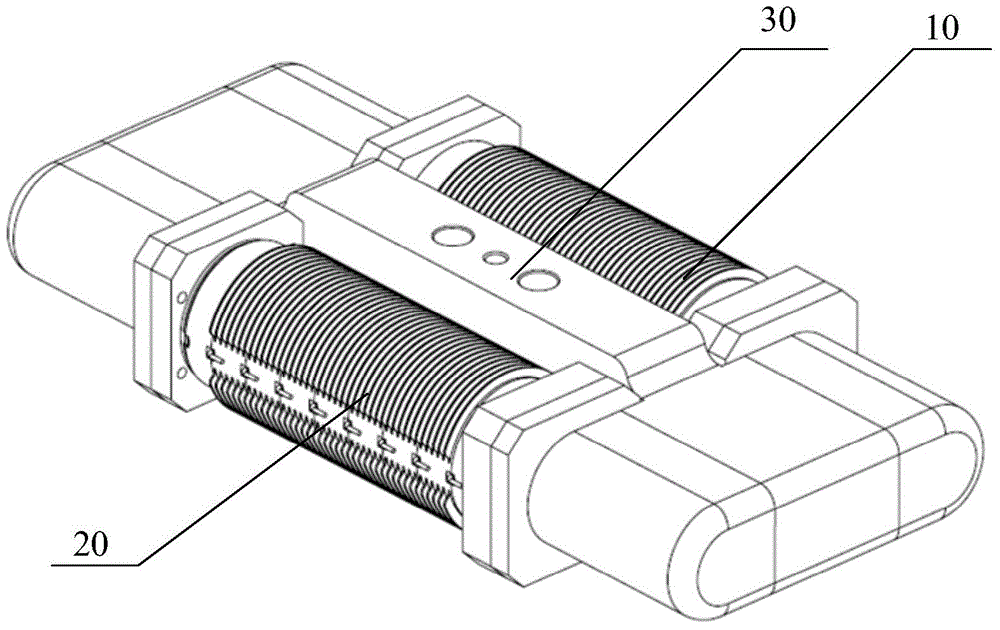

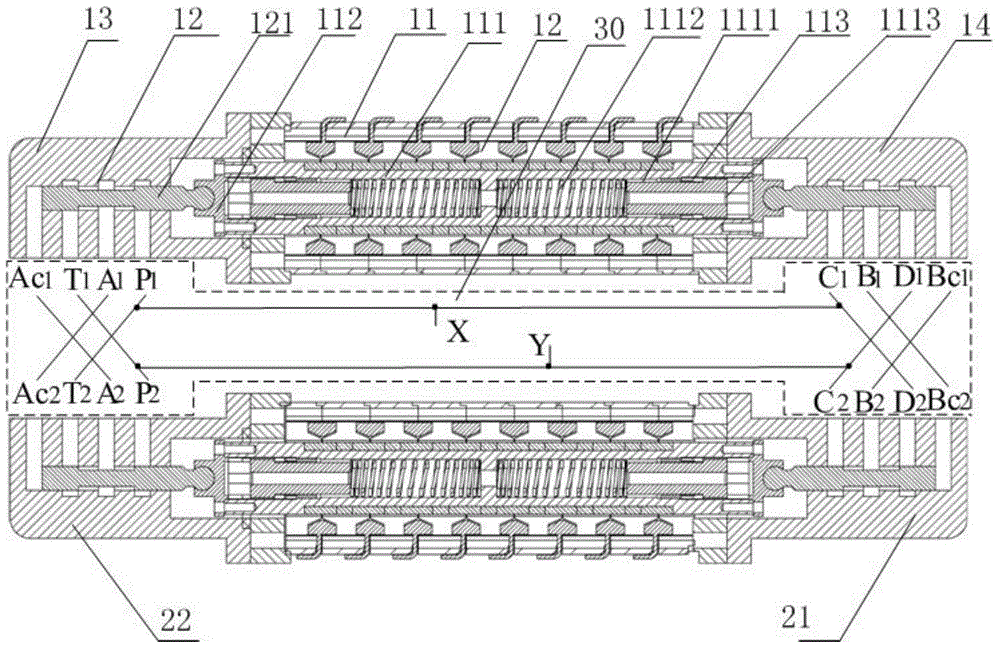

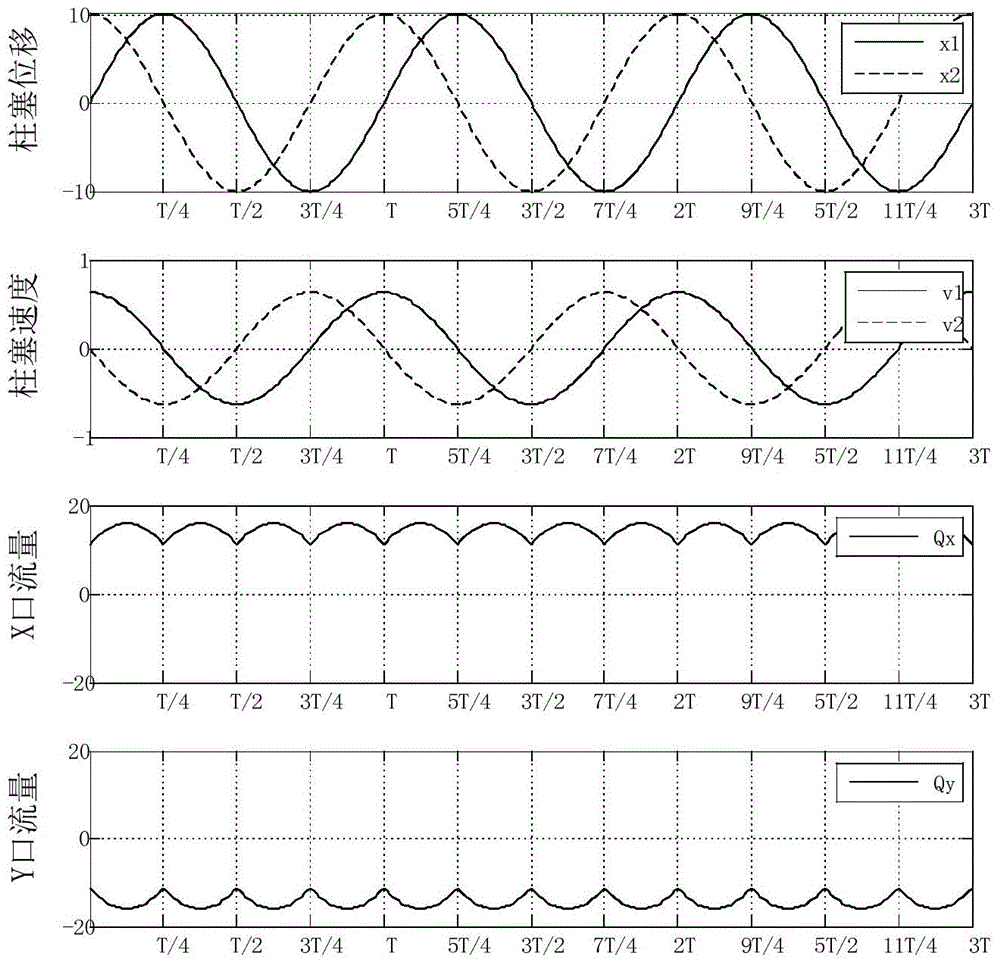

[0020] Such as figure 1 As shown, the present invention provides a double-butterfly coordinated flow distribution pump driven by a linear resonant motor, including at least one pump unit, the pump unit includes two pump modules, and the two pump modules are connected to the oil circuit through a double-butterfly flow distribution valve block 30 ,Such as figure 2 As shown, the pump module includes a linear resonant motor 11. Both ends of the line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com