Bottle cap gap width estimation method by using transmission type illuminating and imaging system

A technology of slit width and imaging system, applied in the field of image processing, can solve the problems of high false detection rate and affect the accuracy of automatic slit width algorithm, achieve the effect of fast and accurate estimation, and meet the requirements of online real-time detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

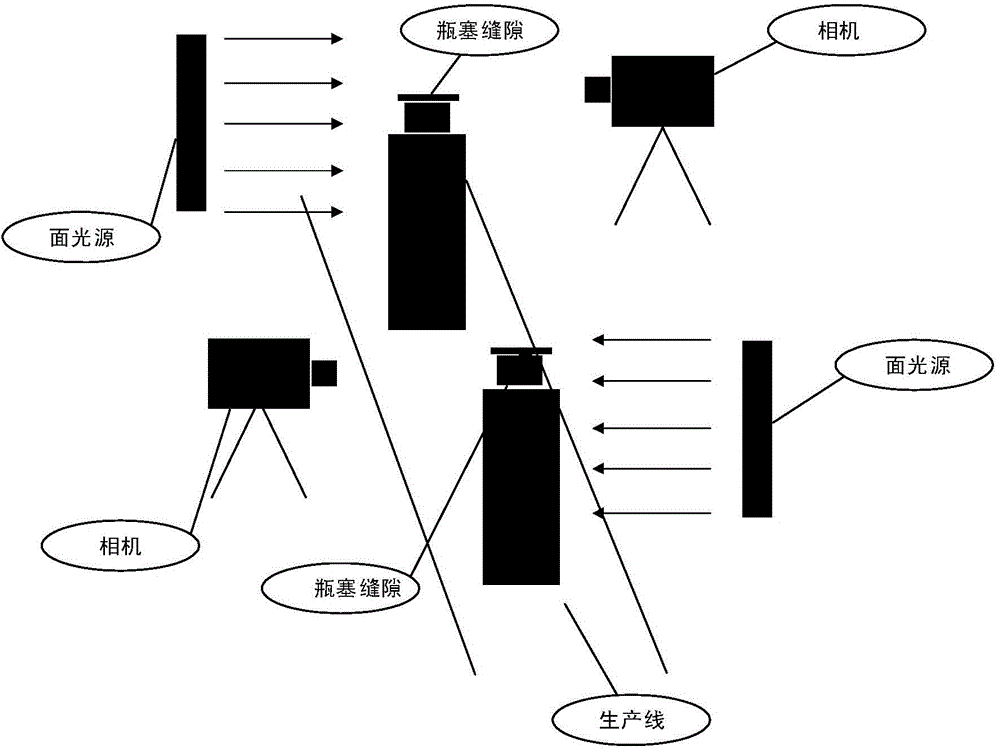

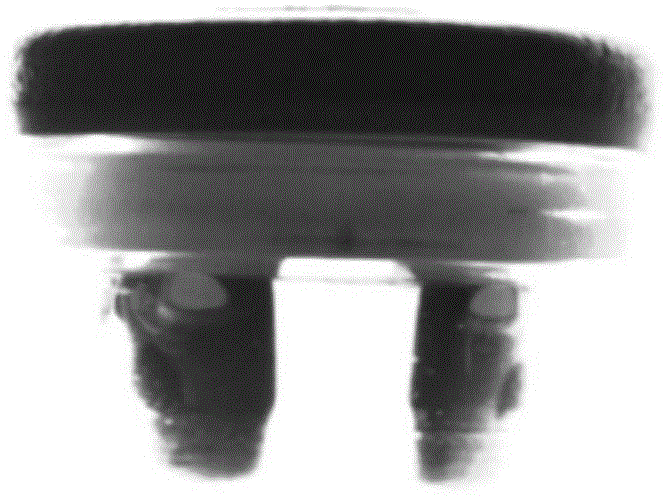

[0020] The method of the invention can be used to accurately estimate the gap width of the bottle cap. The device structure of the transmission illumination imaging system is as follows: figure 1 shown. The use of transmissive lighting can well reflect the outer contour of the bottle cap and the contour of the gap of the bottle cap, eliminating the influence of material reflective characteristics on the visual processing map. At the same time, the positive and negative symmetrical imaging system can effectively estimate the full width of the bottle stopper.

[0021] A method for estimating the gap width of a bottle cap using a transmission illumination imaging system, comprising the following steps:

[0022] (1), such as figure 1 As shown, a transillumination imaging system is constructed. The lighting source is an LED surface light source, which is used to illuminate the gap detection point of the bottle cap to ensure that the gap of the bottle cap is illuminated evenly, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com