Device and method for measuring parameters of non-spherical particles under gas-solid flow condition

A non-spherical particle, parameter measurement technology, applied in the field of multiphase flow measurement, can solve the problem of difficult measurement of spatial attitude parameters, and achieve the solution of inability to use online for a long time, reduce volume, ensure density uniformity and center of gravity consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

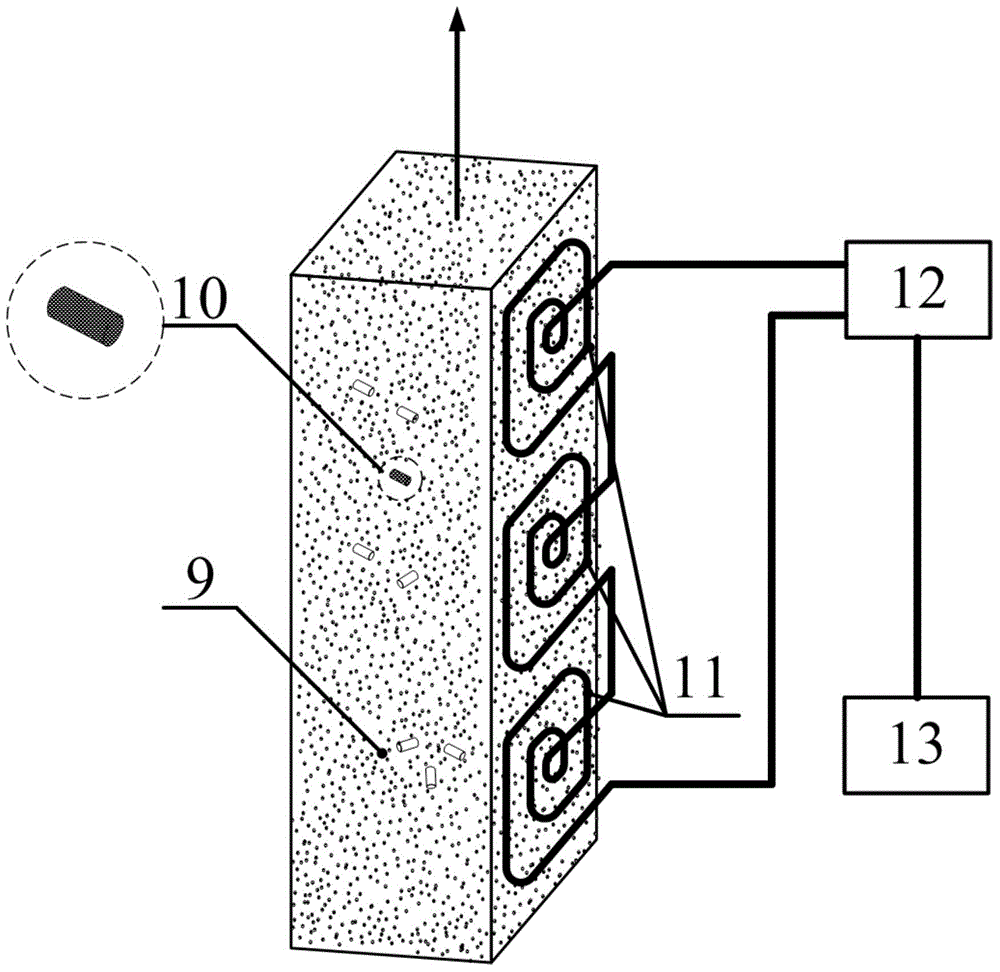

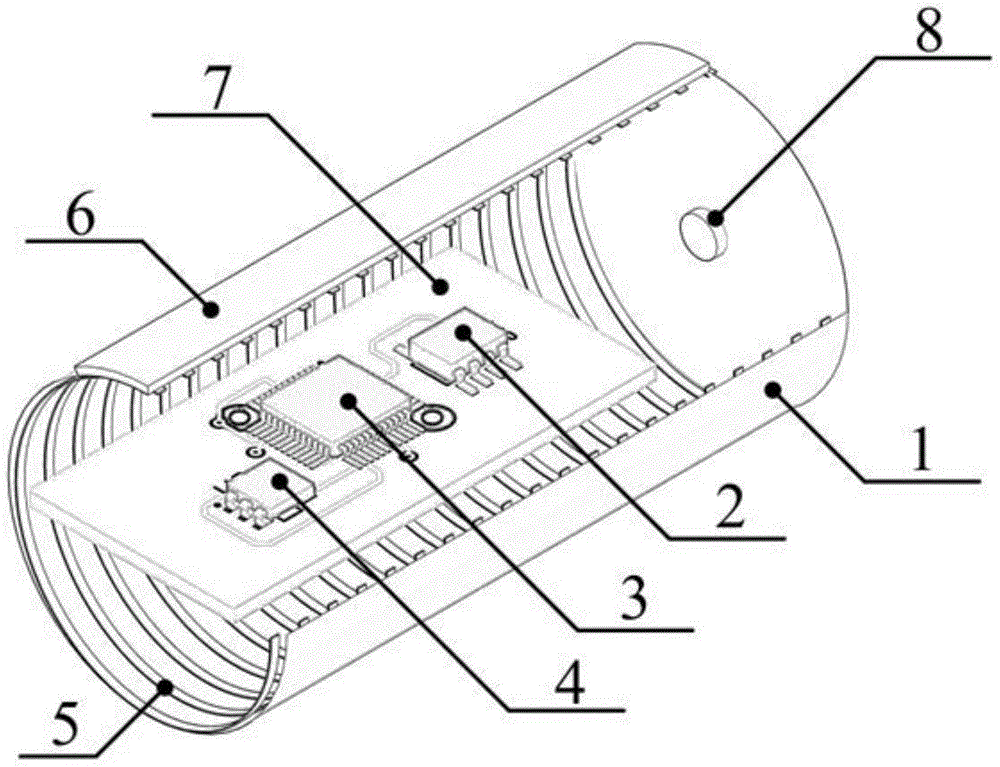

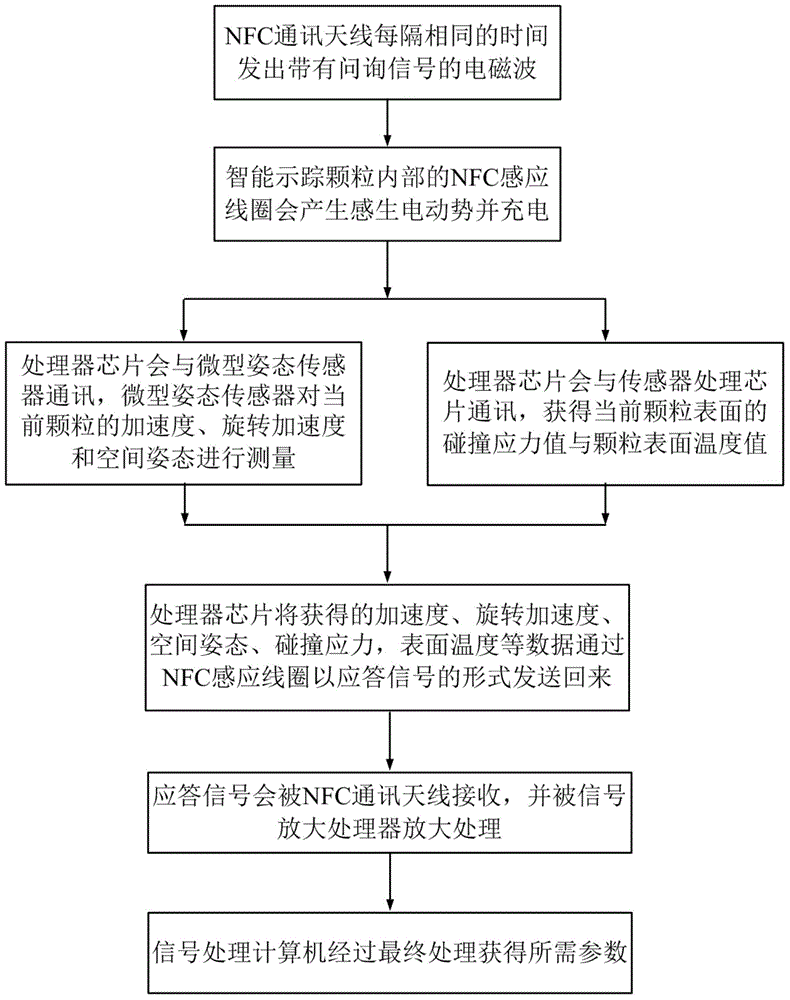

[0027] as attached figure 1 As shown, a device for measuring the parameters of non-spherical particles under the condition of gas-solid flow includes smart tracer particles 10, and the smart tracer particles 10 pass through the micro-attitude sensor 4, temperature sensor 8, and stress sensor 6 arranged in it. And a processor chip 3 with NFC near-field communication function to obtain various measurement parameters, and the obtained various measurement parameters are sent to the outside through the NFC near-field communication function of the processor chip 3, and various dynamics and transmission parameters are obtained after processing. thermal parameters.

[0028] as attached figure 1 and 2 As shown, the specific device structure, installation details and measurement methods are as follows: Before the measurement, it is first necessary to select the measurement ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com