Nozzle block type gas flowmeter calibrating device

A technology of gas flow meter and nozzle device, which is applied in the direction of measuring device, liquid/fluid solid measurement, test/calibration device, etc. It can solve the problems of heavy weight, inconvenient installation, disassembly and maintenance of nozzle box, and large volume of nozzle box and other problems, to achieve the effect of convenient maintenance, increasing the scope of application, and large detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

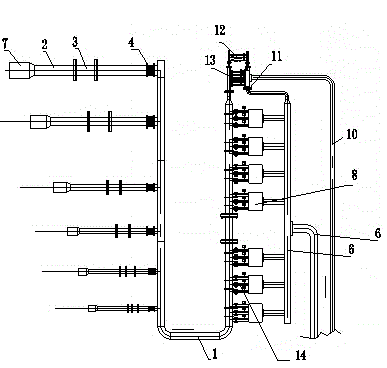

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0022] like figure 1 Shown: a nozzle group type gas flow meter verification device, which includes a manifold 1 with both ends closed, the manifold 1 is a U-shaped structure, and the vertical gas inlet pipe on the front side of the manifold 1 is connected at intervals There are multiple inlet pipes 2 with different calibers, and each inlet pipe 2 is connected to the manifold 1 through bellows 4 respectively. A muffler 7 is installed at the entrance of the front end of the inlet pipe 2, and the air inlet section of the manifold 1 is connected with a plurality of inlet pipes 2 of different calibers at intervals, and the middle parts of the plurality of inlet pipes 2 of different calibers are respectively arranged There are clamping tables 3 for installing gas flowmeters of different sizes.

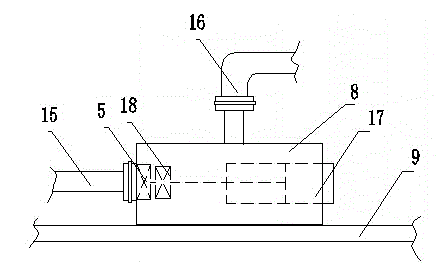

[0023] A plurality of nozzle devices capable of gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com