Device for determining heat-conductivity coefficient

A measuring device and thermal conductivity technology, applied in the field of thermal conductivity measuring devices, can solve the problems of low accuracy, high cost, complicated operation, etc., and achieve the goal of reducing contact thermal resistance, improving accuracy and objectivity, and improving accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

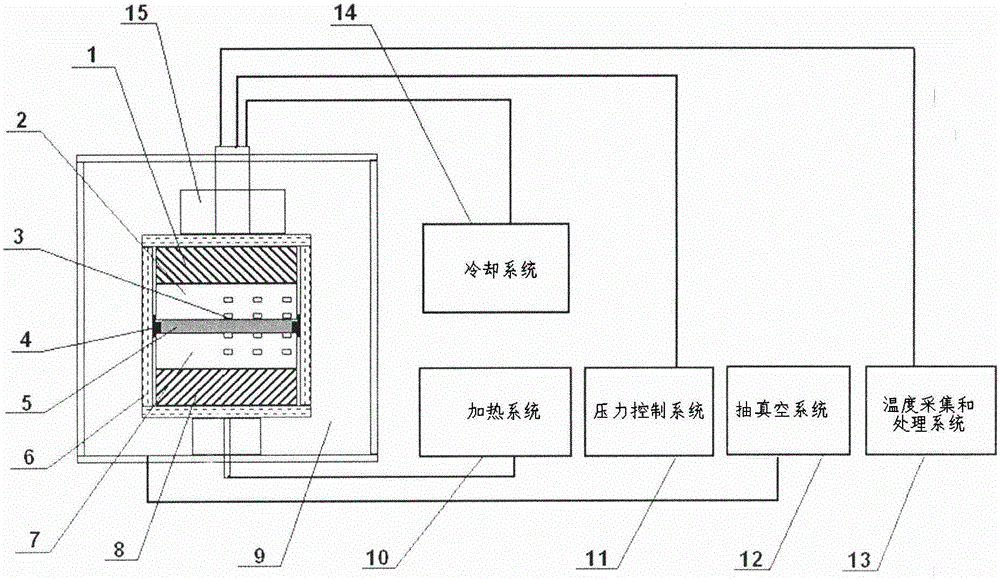

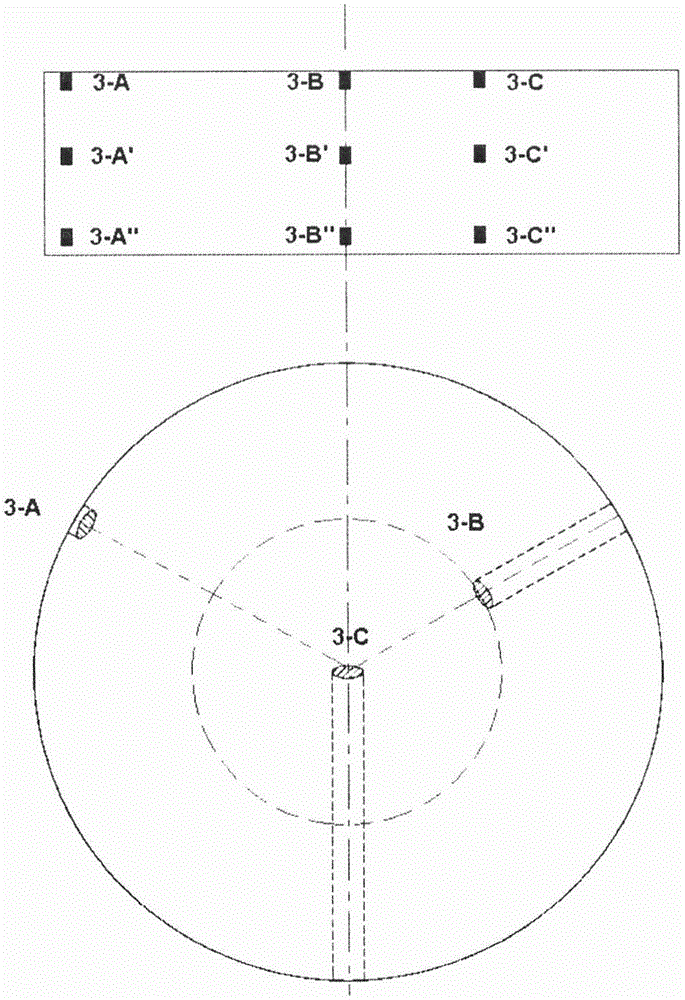

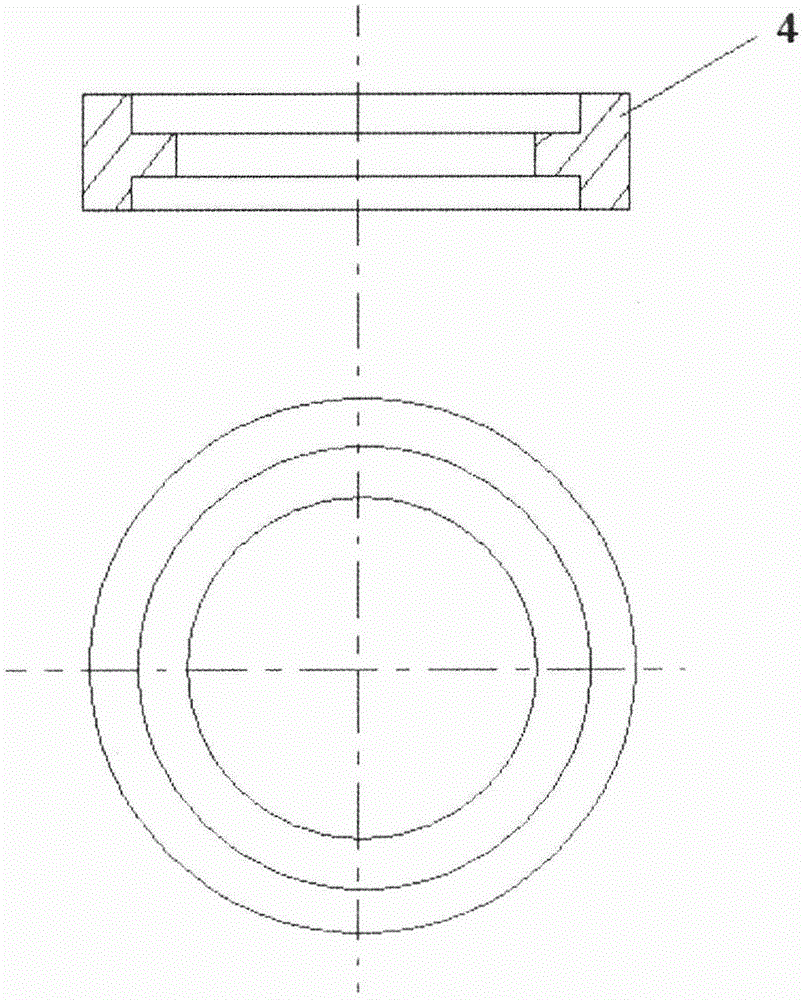

[0046] The device for measuring thermal conductivity of flexible materials is characterized in that: the device includes: a test cavity 9, a hot end heating system 10, a cold end cooling system 14, a vacuum system 12, a temperature acquisition system 13, a pressure control system 11; A test bench 15 with an overall up-and-down structure. From bottom to top, the heating block 8, the lower indenter 7, the sample to be tested 5, the upper indenter 2, and the cooling block 1, are arranged on the surface of the upper and lower indenters. Temperature measurement sensor group 3, temperature measurement sensors are connected to the temperature acquisition and processing system 13; the heating block 8 is connected to the hot end heating system 10, the cooling block 1 is connected to the cold end cooling system 14, and the temperature acquisition and processing system 13 Complete data collection, online processing, and test result output in a timely manner; the setting method of the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com