Method for monitoring relative gravity of surface subsidence in coal mining process

A mining process and surface subsidence technology, which is applied in geophysical measurement, measuring devices, and gravitational field measurement, can solve the problems of reduced accuracy, time-consuming and laborious, and unsuitable for coal mine subsidence monitoring, achieving high accuracy and high monitoring results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

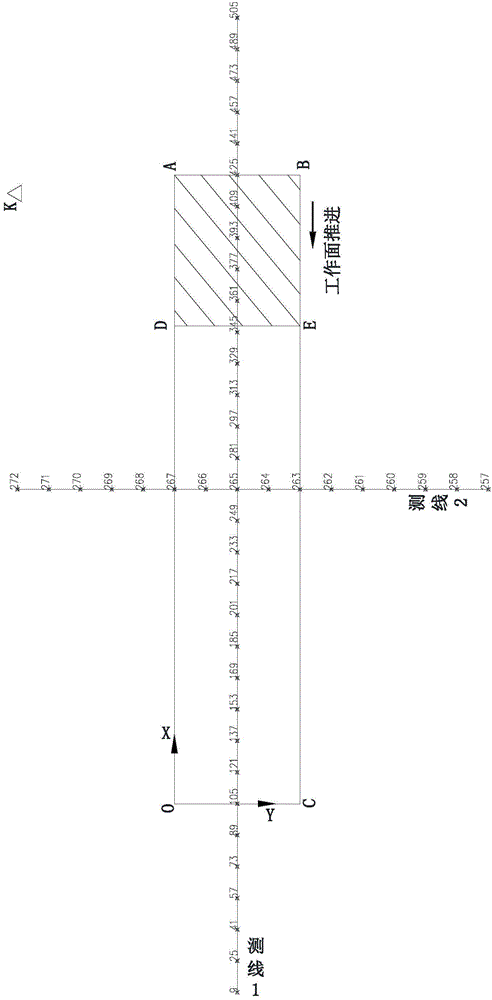

[0081] Such as figure 1 As shown, taking a coal mine as an example, there is a gravity observation reference point K in the mining area, and the gravity value of this point remains unchanged. Such as figure 1 As shown, the working face is 1000 meters long in strike direction and 200 meters wide in inclination.

[0082] For convenience, figure 1 Only the layout of the monitoring points along the strike main section and the inclined main section of the coal seam is given in the paper. Such as figure 1 As shown, there are 47 gravity monitoring points in the figure.

[0083] Taking the relative gravity monitoring in the previous two phases as an example, use a relative gravimeter to monitor the gravity monitoring point once before the mining of the working face. Perform a relative gravity monitor.

[0084] The second step is to calculate the gravity change value of the two adjacent monitoring points (see Table 1 below for details)

[0085] Table 1: The gravity change value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com