A Fault Injection Method

A fault injection and fault technology, which is applied in the direction of instruments, simulators, control/regulation systems, etc., can solve problems such as low time accuracy, fault injection, and system intrusion under test, and achieve broad market prospects, improve reliability, and quickly The effect of the change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The content and effects of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] The design method step of the present invention is as follows:

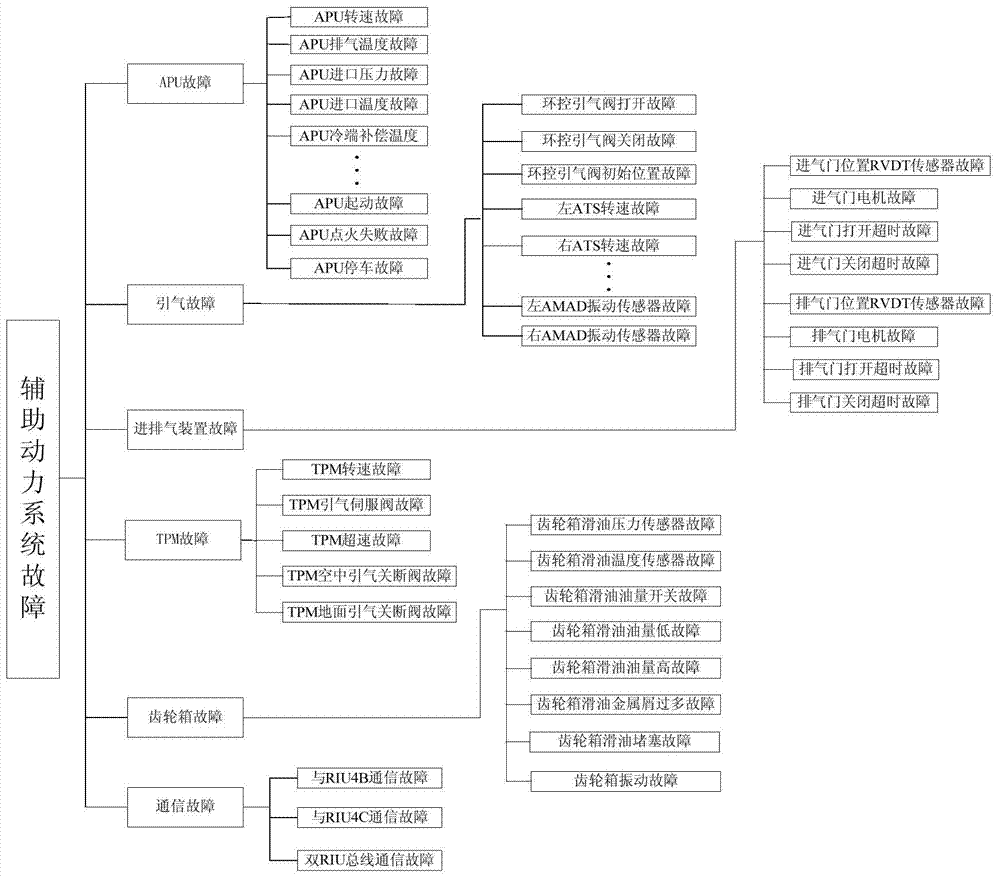

[0030] Step 1, establishment of fault tree. The auxiliary power system has six types of faults, including APU fault, bleed air fault, intake and exhaust device fault, TPM fault, gearbox fault, and communication fault. The established fault tree of the auxiliary power system is as follows: figure 2 shown.

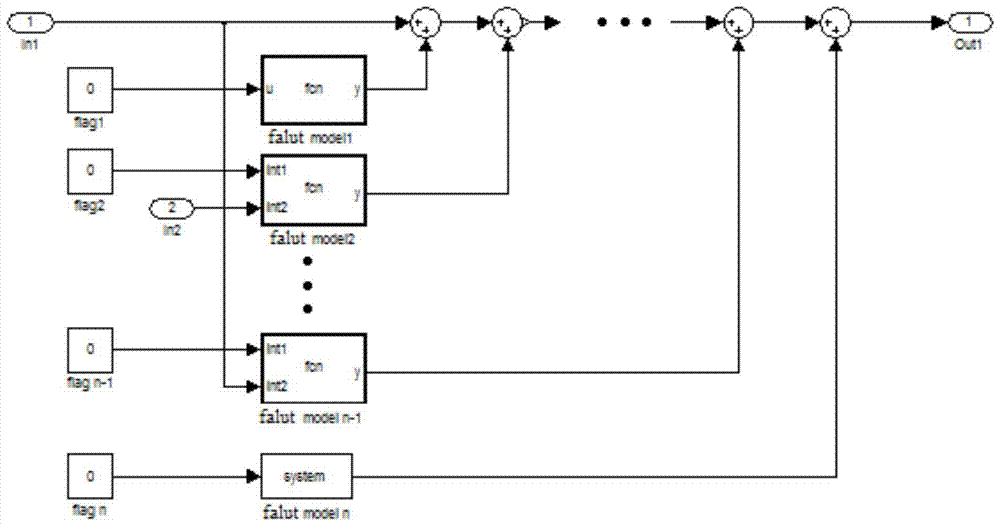

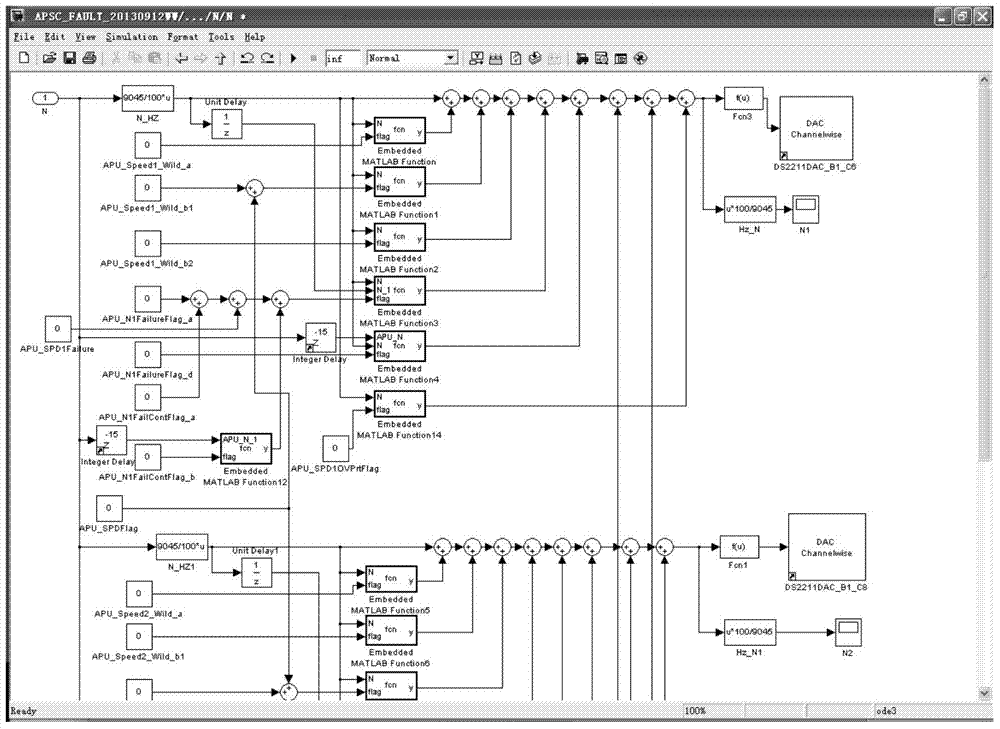

[0031] Step 2, establishment of fault simulation model. Each fault branch on the fault tree has a variety of triggering conditions. According to the triggering conditions of each fault, the Simulink model of the fault is established. In order to quickly and conveniently realize the simulation of multiple fault injection, the fault is added to the normal signal flow input. The trigger point of the model, such as image 3 , 4 Partial Simulink model of APU tach fau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com