Comb line slow wave structure working on high-order pass band

A slow-wave structure and comb-line technology, applied in the field of microwave vacuum electronic devices, can solve the problems of poor high-frequency and high-power performance, and achieve the effect of improving power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

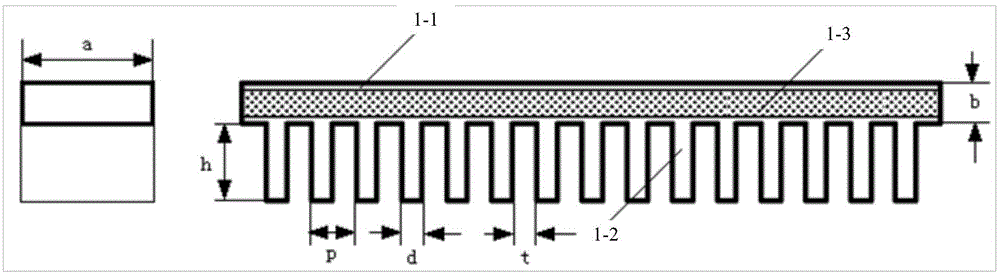

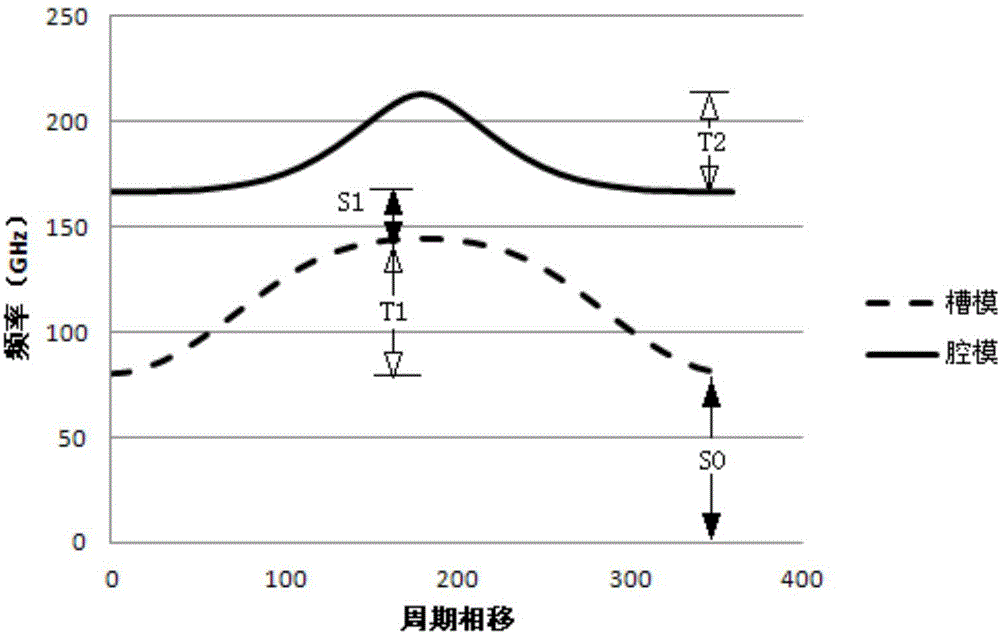

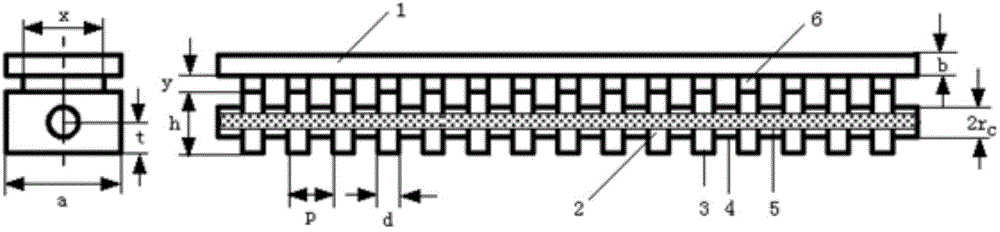

[0022] In order to obtain a slow wave structure suitable for high-power terahertz return wave oscillators, the present invention sets the interaction area on the comb line while maintaining the inherent micromachining compatibility of the comb line, good cold characteristic parameters and simple coupling advantages. In the cavity mode area, the slot mode area and the cavity mode area are connected through a small-sized waveguide as a filter circuit, and the slot mode electromagnetic field is isolated from the interaction area by using its lower cut-off characteristics, so as to solve the possible mode competition in the low passband and make the electron injection Only the required cavity-mode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com