Anti-condensation device with self-adaptation control and control method

A technology of self-adaptive control and control method, applied in the direction of non-electric variable control, control/regulation system, simultaneous control of multiple variables, etc., can solve the problems of energy waste, blockage of air duct, and large consumption of electric energy resources, etc., to avoid easy The effect of blocking the air duct and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. Those skilled in the art should understand that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0025] The model of the electrical component adopted in the present embodiment:

[0026] Environmental temperature and humidity sensor: SI7005 digital calibration-free temperature and humidity sensor

[0027] Condensing end temperature sensor, cooling end temperature sensor: NTC thermistor

[0028] Electronic cooling element: TE12705

[0029] Central control unit main control chip: C8051F3xx series MCU

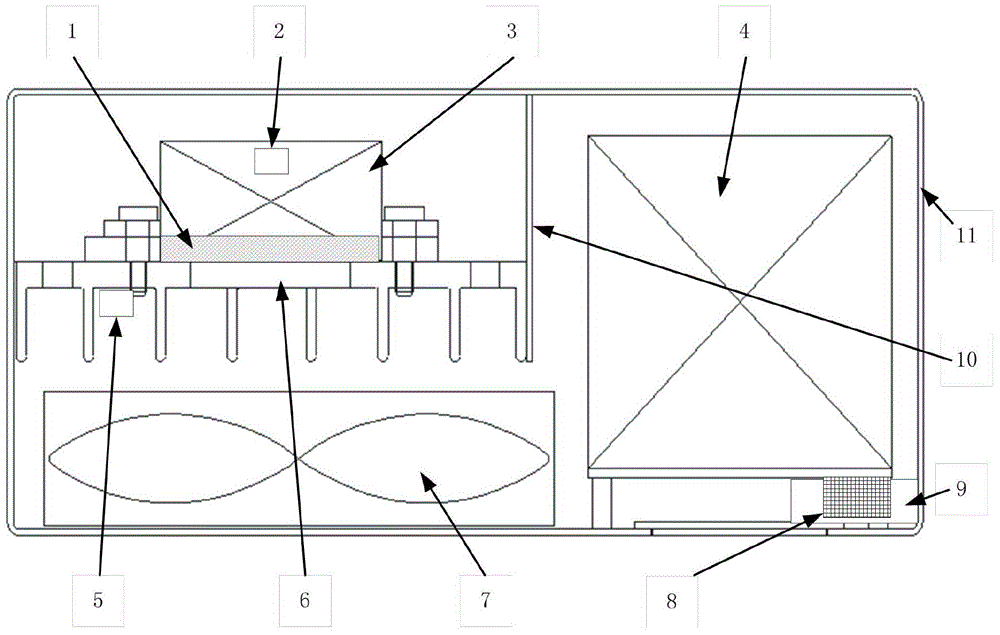

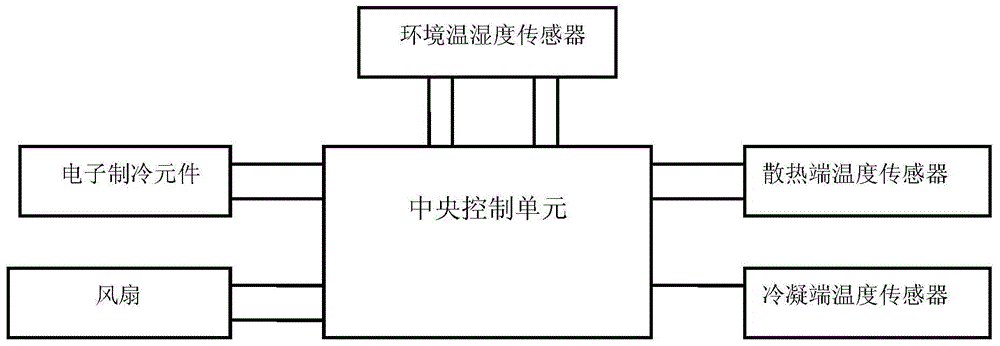

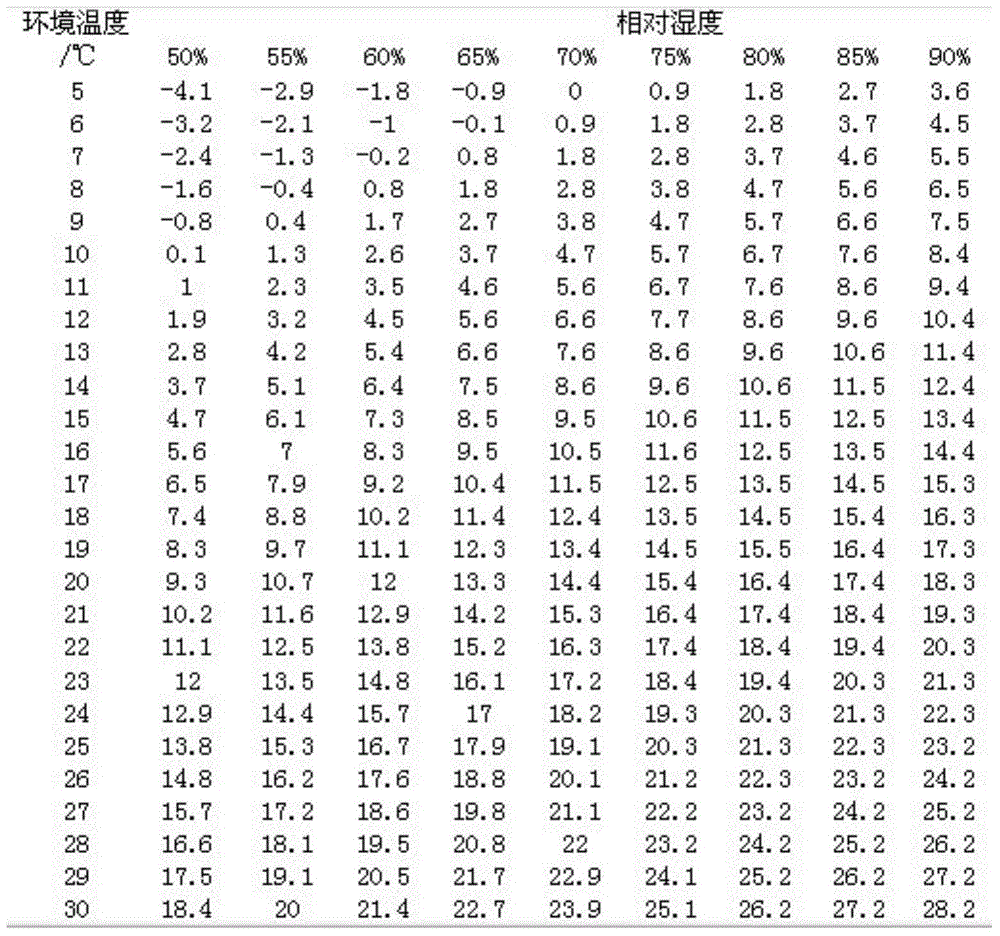

[0030] Such as figure 1 As shown, an adaptive control anti-condensation device includes a housing, an electronic condensation assembly installed inside it, and a central control unit. The shell is divided into two chambers by a partition, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com