Numerical control residual heat recycling type tea leaf forming fragment enhancer

A technology of waste heat recovery and aroma enhancing machine, which is applied in tea treatment before extraction, etc. It can solve the problems of low use efficiency, inability to make full use of hot air, and insignificant energy-saving effect, and achieve easy operation, good appearance, and remarkable energy-saving effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

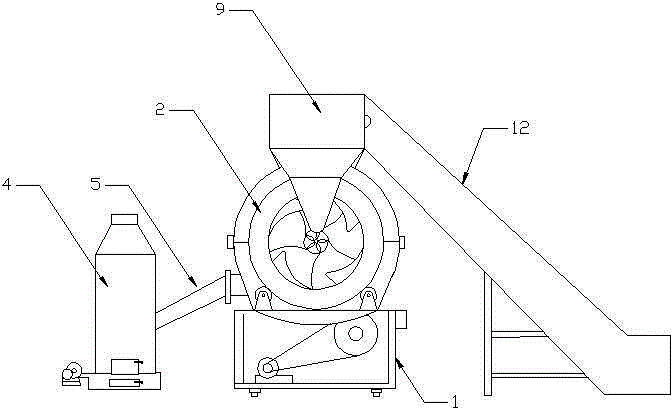

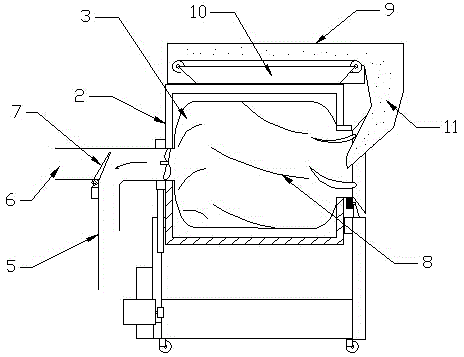

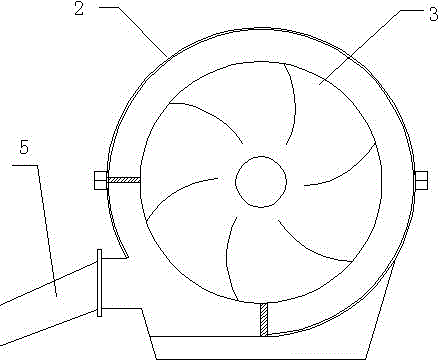

[0024] Specific implementation methods: such as figure 1 , 2 As shown, a numerically controlled waste heat recovery type tea forming and aroma enhancing machine includes a frame, an oven 2 arranged on the frame 1, an electronic control box, an automatic loading mechanism, and the like. An insulation layer is provided on the inner wall of the oven. The inside of the oven is provided with a drum 3, one end of the drum 3 is the tea inlet and outlet and the other end is an air outlet, and the air outlet is provided with a fan controlled by an electronic control box. The air outlet is communicated with the air inlet of the hot blast stove 4 through the hot blast recovery pipeline 5, and the hot blast discharged from the hot blast stove 4 passes through the drum 3, and then is imported into the hot blast stove 4 through the air outlet for recycling. The hot air recovery pipe 5 is provided with an emptying port 6, and the emptying port 6 is provided with a swing leaf 7 for adjusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com