Thermal bonding invisible socks

A technology of invisible socks and thermal bonding, applied in socks, pantyhose, clothing, etc., can solve the problems of uncomfortable wearing, short service life, poor elasticity, etc., and achieve the effect of comfortable wearing, strong air permeability and beautiful products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

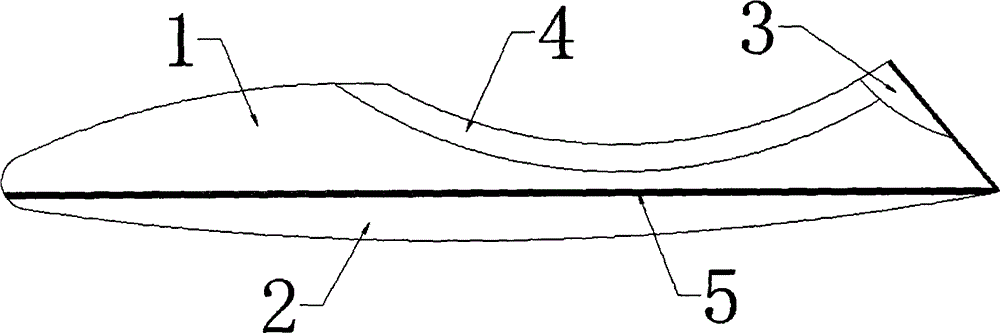

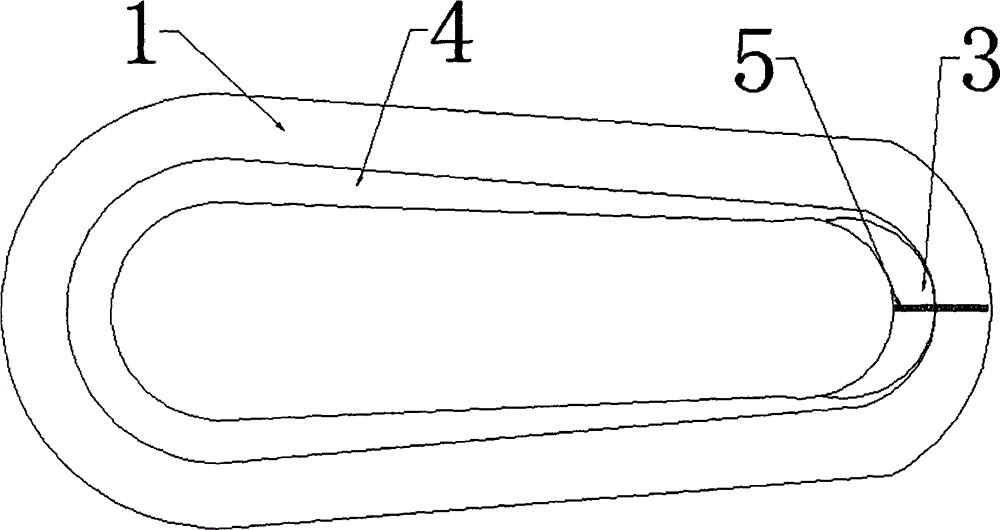

[0022] The preferred implementation of the heat-bonded invisible socks of the present invention will be described in detail below with reference to the accompanying drawings.

[0023] combine figure 1 and figure 2 Show the specific embodiment of the heat-bonded invisible socks of the present invention: the heat-bonded invisible socks include a sock upper 1 and a sock sole 2, and are characterized in that: the heat-bonded invisible socks include a sheet-shaped sock sole 2 and an opening The sock upper 1, the sock sole 2 and the sock upper 1 are sewn together, and a triangular heel point plastic sheet 3 is provided at the rear of the sock upper 1, and the heel point plastic sheet 3 is sewn on the heel of the sock upper 1 in an inverted triangle shape, and the heel The lowest point of the point plastic sheet 3 is higher than the suture line 5 of the sock bottom 2 and the sock top 1, and a circle of hot-melt adhesive film 4 is provided at the cuff of the sock top 1. The manufact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com