PVC (polyvinyl chloride) antistatic glove

An antistatic and antistatic agent technology, applied in the field of PVC antistatic gloves, can solve the problems of poor glove comfort, complex production process, interference with the processing process, etc., and achieve superior antistatic effect, good antistatic effect and simple production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

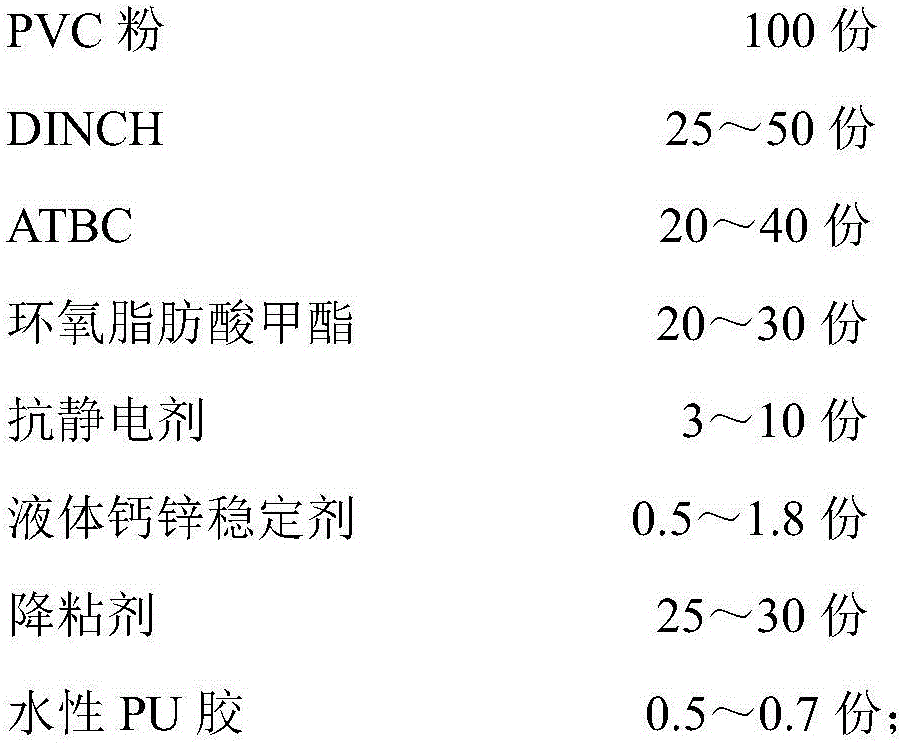

[0027] PVC antistatic gloves are made of the following raw materials in parts by weight:

[0028]

[0029] The production process includes the following steps:

[0030] (1) Primary batching: Mix DINCH, ATBC, epoxy fatty acid methyl ester and polyoxyethylene glyceryl ether and stir, then add PVC powder, CZ-F990, and 10 parts of D70 in turn for stirring to obtain primary batching;

[0031] (2) standing defoaming: the primary ingredients are standing defoaming;

[0032] (3) Secondary batching: add 15 parts of viscosity reducer to the material prepared in step (2), and stir evenly;

[0033] (4) Primary impregnation: filter the secondary ingredients prepared in step (3) and add them to the trough, preheat the hand mold to 70°C and then impregnate, the impregnation temperature is 50°C;

[0034] (5) Primary plasticization: put the impregnated hand mold in an oven and bake at 210°C for 6 minutes;

[0035] (6) Secondary impregnation: add water-based PU glue into softened water an...

Embodiment 2

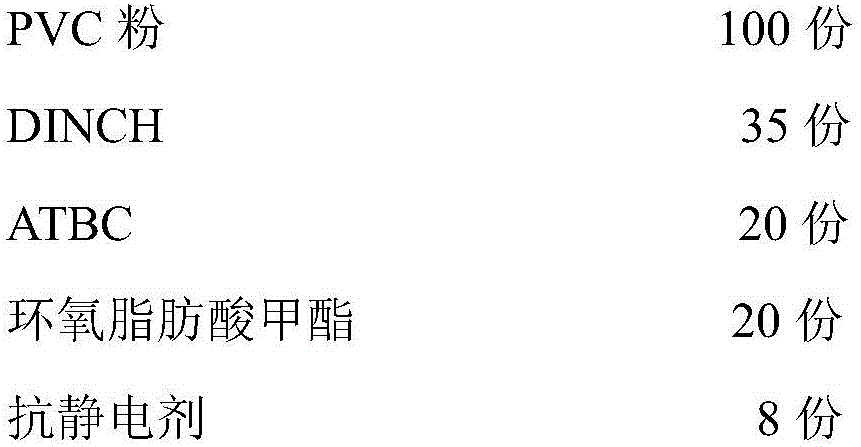

[0043] PVC antistatic gloves are made of the following raw materials in parts by weight:

[0044]

[0045] The production process includes the following steps:

[0046] (1) Primary batching: Mix DINCH, ATBC, epoxy fatty acid methyl ester and polyoxyethylene glyceryl ether and stir, then add PVC powder, CZ-F990, and 10 parts of D70 in turn for stirring to obtain primary batching;

[0047] (2) standing defoaming: the primary ingredients are standing defoaming;

[0048] (3) Secondary batching: add 15 parts of viscosity reducer to the material prepared in step (2), and stir evenly;

[0049] (4) Primary impregnation: filter the secondary ingredients prepared in step (3) and add them to the trough, preheat the hand mold to 70°C and then impregnate, the impregnation temperature is 50°C;

[0050] (5) Primary plasticization: put the impregnated hand mold in an oven and bake at 210°C for 6 minutes;

[0051] (6) Secondary impregnation: add water-based PU glue into softened water an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com