Automatic Smart Soymilk Machine

A soymilk machine, fully automatic technology, applied in milk substitutes, beverage preparation devices, household appliances, etc., can solve the problems of the layout limitation of the whole machine, the inability to achieve smooth blanking, and jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

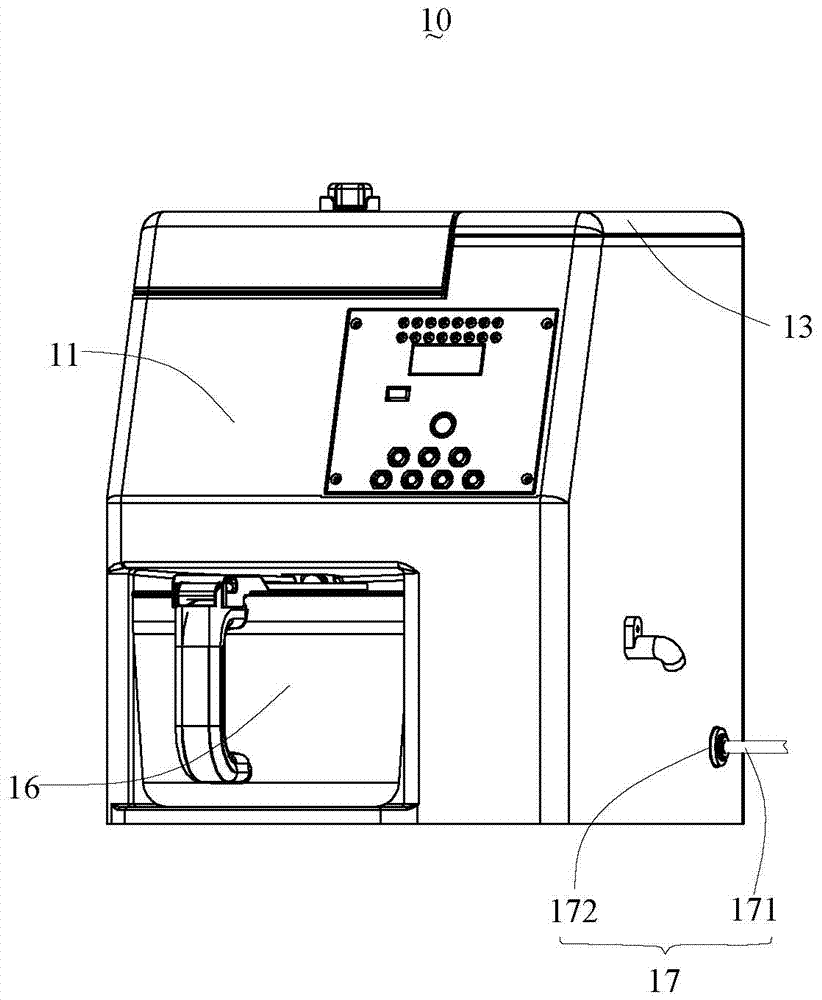

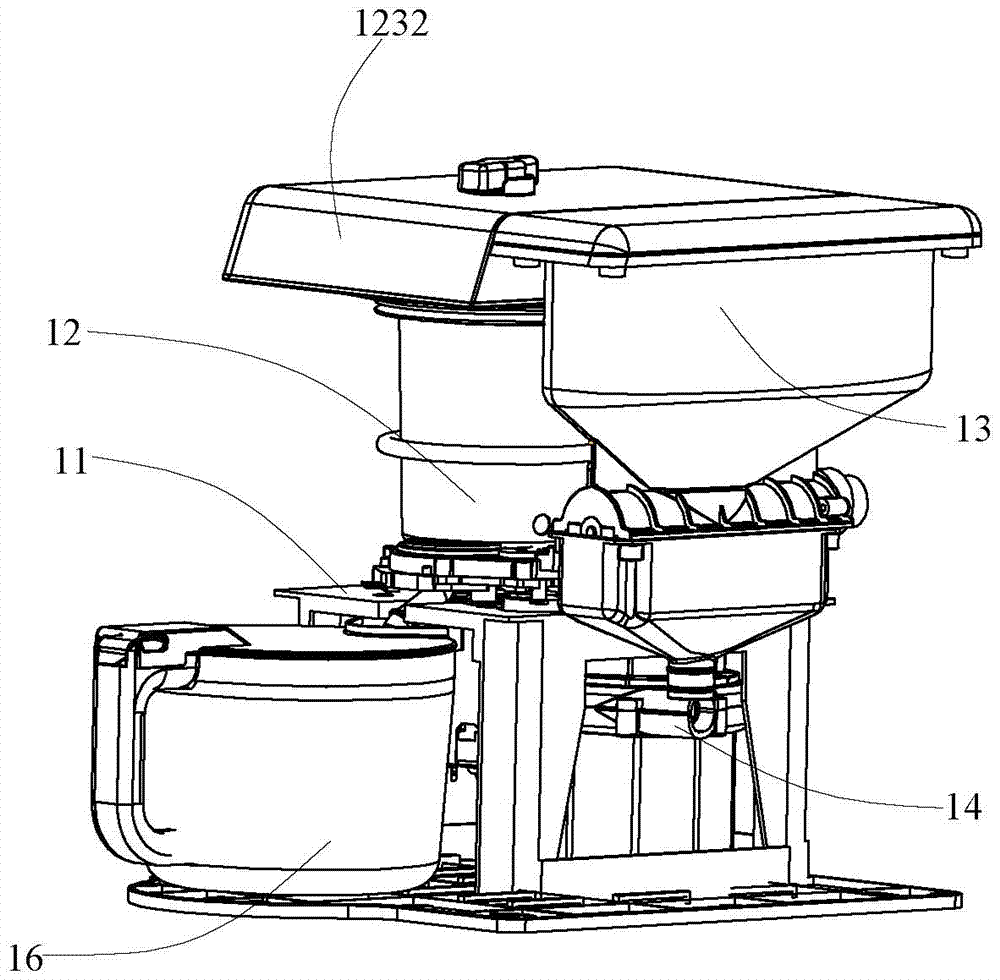

[0044] Please also refer to figure 1 and figure 2 The fully automatic intelligent soymilk machine 10 includes a machine base 11, a pulping assembly 12, a material storage assembly 13, an automatic feeding device 14, a pulp receiving cup 16, an automatic water feeding assembly 17 and a control unit (not shown in the figure), The pulping component 12 , material storage component 13 , automatic feeding device 14 , slurry receiving cup 16 , automatic water feeding component 17 and control unit are respectively arranged on the machine base 11 .

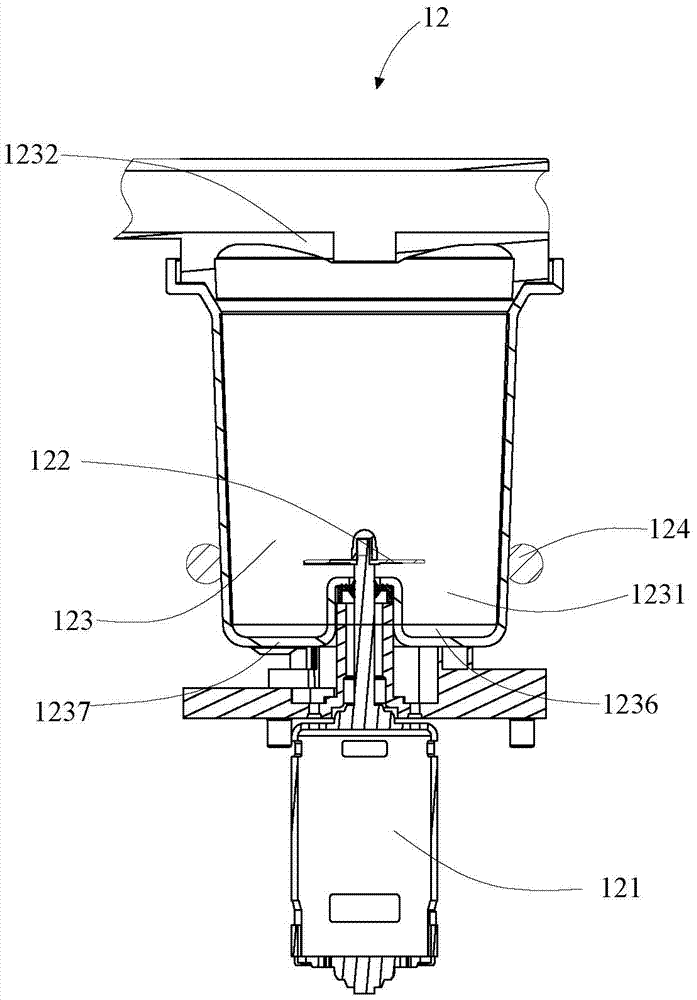

[0045] Please also refer to image 3 , in this embodiment, the pulping assembly 12 includes a motor 121, a crushing tool 122, a pulverizer 123 and a heating device 124 for heating the pulverizer 123, the motor 121 and the heating device 124 are electrically connected to the control unit, and the motor 121 is located below the pulverizer 123. The motor shaft of the motor 121 extends into the pulverizer 123 from the bottom of the pulveriz...

Embodiment approach 2

[0065] see Figure 9 Shown is the second preferred embodiment of the automatic intelligent soybean milk machine of the present invention. The difference between the automatic intelligent soybean milk machine 20 and the automatic intelligent soybean milk machine 10 is that the automatic water inlet component 21 includes a water tank 211 and a water inlet pipe 212. One end of the water inlet pipe 212 communicates with the water tank 211 , and the other end of the water inlet pipe 212 communicates with the water inlet 221 of the pulverizer 22 .

[0066] In this embodiment, the water tank 211 is arranged around the pulverizer 22, the water inlet 221 of the pulverizer 22 can be arranged on the side wall and the bottom wall of the pulverizer 22, and the cover 23 closes the opening of the pulverizer while It is also used to close the opening of the water tank 211.

[0067] In this way, the heating device 124 can heat the water in the water tank 211 while heating the pulverizer 22 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com