Reaction kettle device with inserted tube for producing butyl acrylate

A technology of butyl acrylate and reactor, which is applied in the preparation of carboxylic acid esters, chemical/physical/physicochemical nozzle reactors, and the preparation of organic compounds. It can solve problems such as incomplete reactions and reduce polymerization and consumption. , the effect of speeding up the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

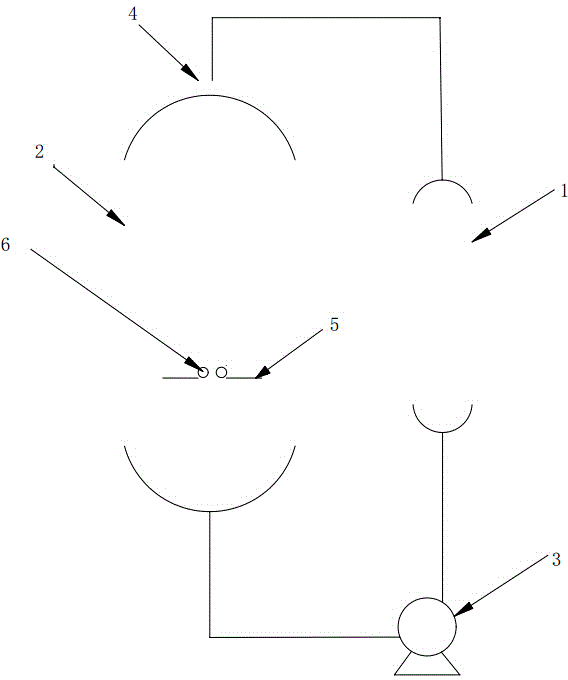

[0010] A kind of reaction still device that band intubation is produced butyl acrylate described in present embodiment 1, such as figure 1 As shown, it includes a reboiler 1, a reactor 2 connected to the reboiler and a bottom material pump 3 with a filter, and the reactor is connected to the bottom material pump; the reboiler is inserted through a reactor tube inserted into the reactor 4. Connect to the reactor; the bottom of the reactor insert is provided with a baffle 5 to cover the bottom port, and a cross-shaped opening 6 is provided on the bottom side of the reactor insert. The raw materials butanol and acrylic acid enter the reboiler for heating, then enter the bottom of the reactor, spray out to the reactor in a cross shape, and react with the catalyst in the reactor to form butyl acrylate; the reactor insert plays a stirring role and reduces Polymerization speeds up the reaction and reduces consumption; the baffle at the bottom of the intubation of the reactor can prev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com