Preparation method of hydrogen storage material

A technology for hydrogen storage materials and production methods, applied in separation methods, chemical instruments and methods, hydrogen, etc., can solve the problems of incomplete reaction of graphite powder, low purity of graphene, etc. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

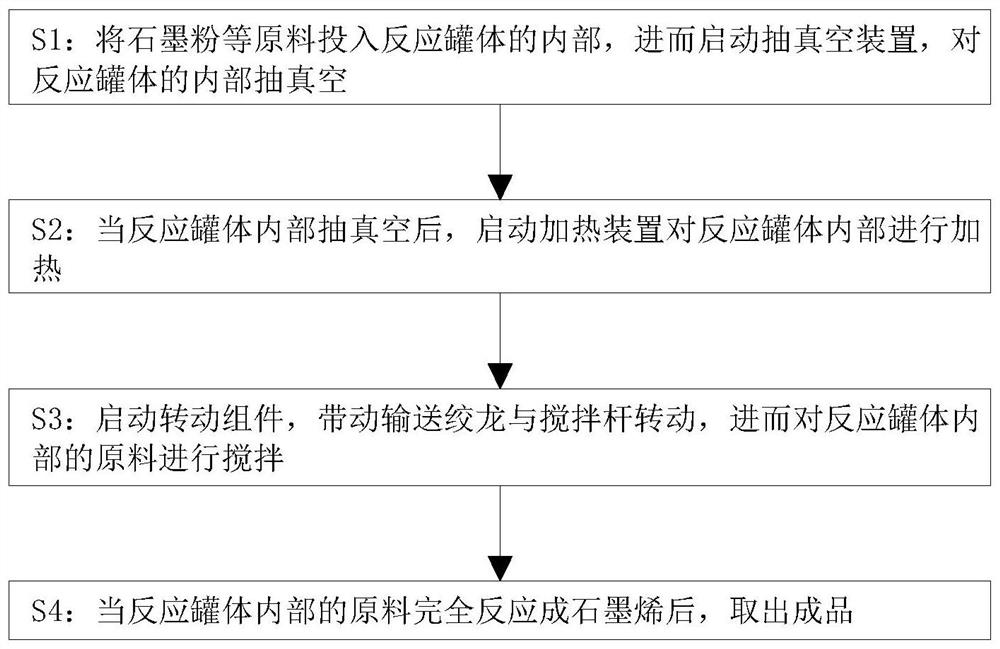

[0034] Such as Figure 1 to Figure 8 As shown, a method for preparing a hydrogen storage material according to the present invention is characterized in that: the production method steps of the hydrogen storage material are as follows:

[0035] S1: put graphite powder and other raw materials into the inside of the reaction tank, and then start the vacuum device to vacuum the inside of the reaction tank;

[0036] S2: After the inside of the reaction tank is evacuated, start the heating device to heat the inside of the reaction tank;

[0037] S3: Start the rotating assembly, drive the conveying auger and the stirring rod to rotate, and then stir the raw materials inside the reaction tank;

[0038] S4: After the raw materials in the reaction tank are completely reacted into graphene, take out the finished product.

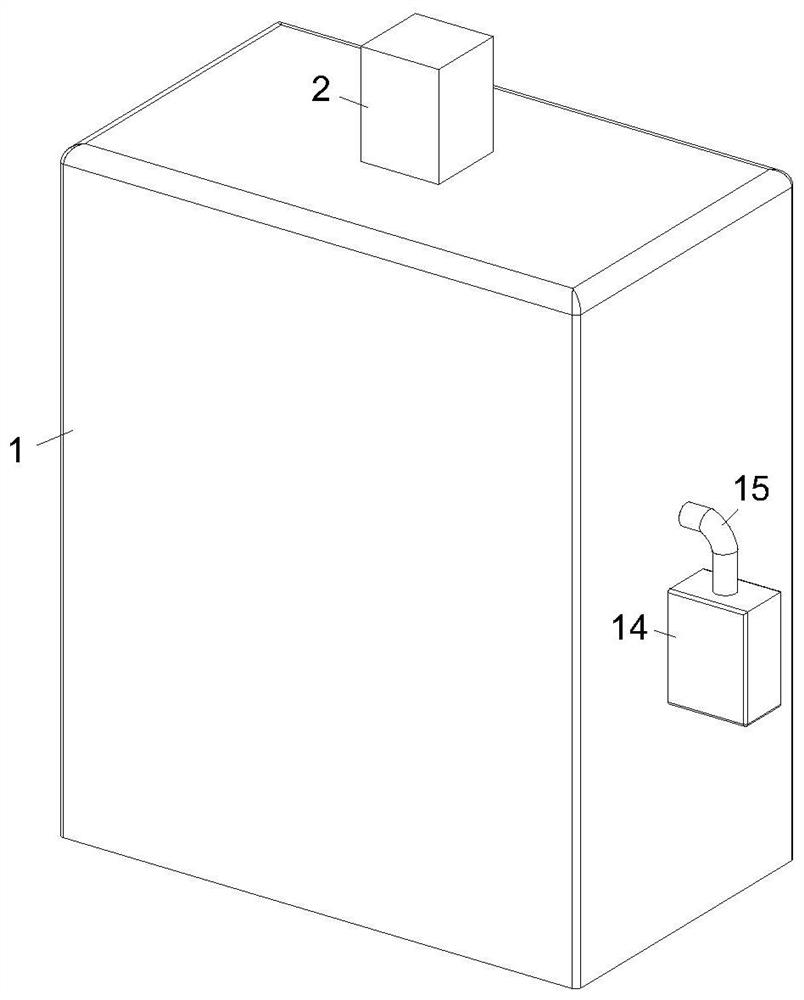

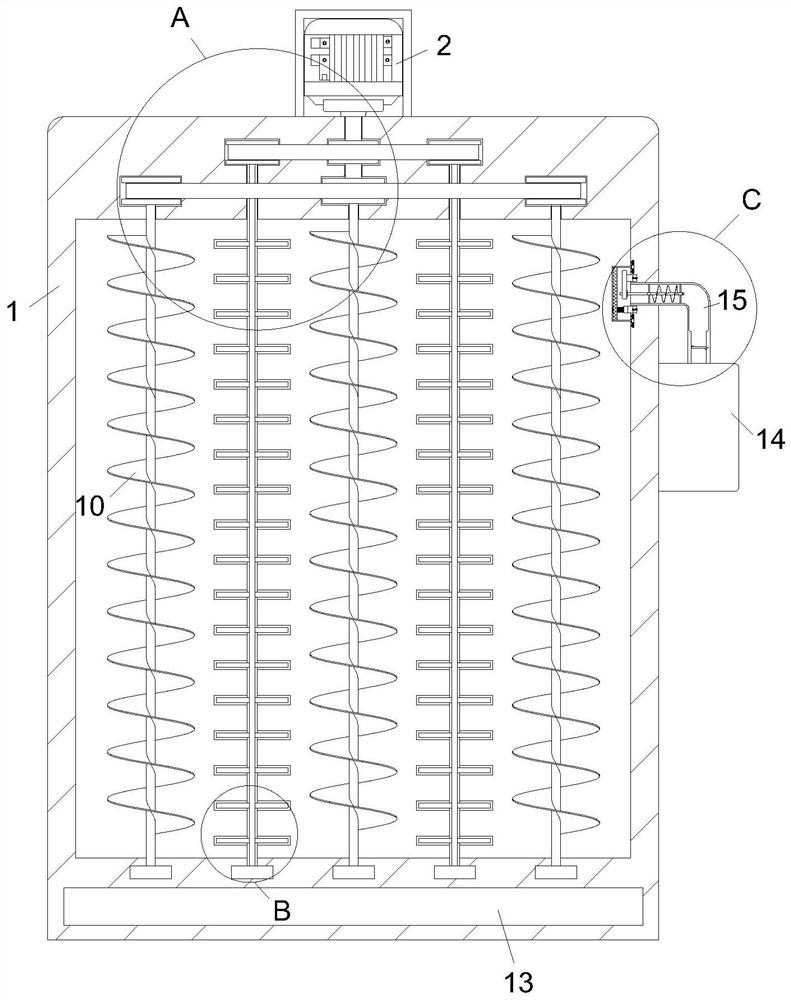

[0039] The top of the reaction tank 1 is equipped with a rotating assembly; the bottom of the rotating assembly is provided with a conveying auger 10 and a stirring...

Embodiment 2

[0047] Such as Figure 9 As shown in Comparative Example 1, as another embodiment of the present invention, a ball 32 is buckled and connected to the side wall of the oblique push block 28; the ball 32 is arranged at a position corresponding to the eccentric wheel 22; When working, when the eccentric wheel 22 contacts the side wall of the oblique push block 28, and then promotes the oblique push block 28 to slide, the ball 32 can reduce the friction between the eccentric wheel 22 and the oblique push block 28, thereby making There is less wear between the eccentric wheel 22 and the balls 32 .

[0048] Working principle: when working, when graphene needs to be prepared, graphite powder can be added to the inside of the reaction tank 1, and then the vacuum device 14 is started, and the internal air of the reaction tank 1 is drawn out through the exhaust pipe 15, so that the reaction A vacuum environment is formed inside the tank body 1, and then the heating device 13 is started...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com