Electroceramic white glaze brand glaze and preparing method thereof

A trademark and white glaze technology, applied in the field of electric porcelain white glaze trademark glaze and its preparation, can solve the problems of blurred logo, edge melting, weak bonding force, etc., and achieve the effects of improving stamping strength, good lubricating effect, and not easy to dry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

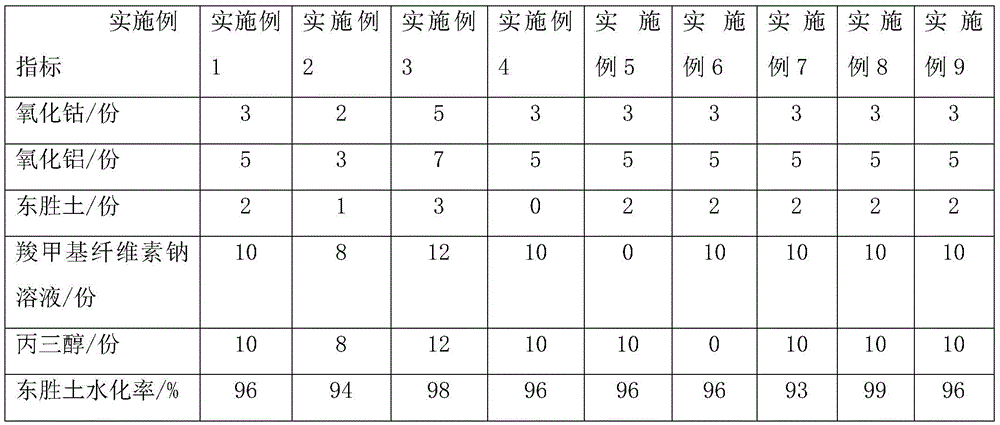

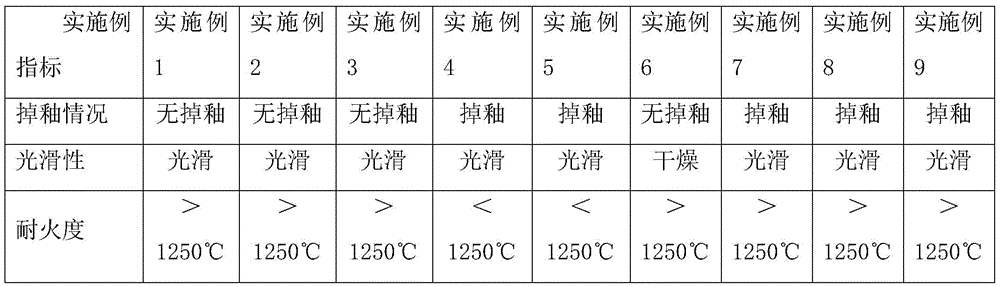

Embodiment 1

[0045] An electric porcelain white glaze trademark glaze, which comprises the following raw materials in parts by weight: 3 parts of cobalt oxide, 5 parts of aluminum oxide, 2 parts of Dongsheng soil, 10 parts of 1.6%-2.4% sodium carboxymethyl cellulose solution, acrylic acid 10 parts of triol.

[0046] The specific preparation method of the electric porcelain white glaze trademark glaze of the present embodiment is as follows:

[0047] Preparation of blue colorant:

[0048] (1) After mixing 3 parts of cobalt oxide and 5 parts of aluminum oxide in proportion, carry out grinding, and the fineness requirement is 340-360 mesh sieve balance is 0;

[0049] (2) put the mixture after grinding in step 1 into the kiln and calcined for 10 minutes, the kiln temperature of the calcining is controlled within the range of 1100-1350°C, and the blue toner is obtained after calcining;

[0050] Trademark Glaze Preparation:

[0051] (3) Take 6-10 parts of blue toner, 2 parts of Dongsheng soil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com