Photocatalytic reagent and application on aluminized paper

A photocatalytic reaction and photocatalytic reactor technology, which is applied in the fields of physical treatment of paper, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of small application range and few types of volatile substances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

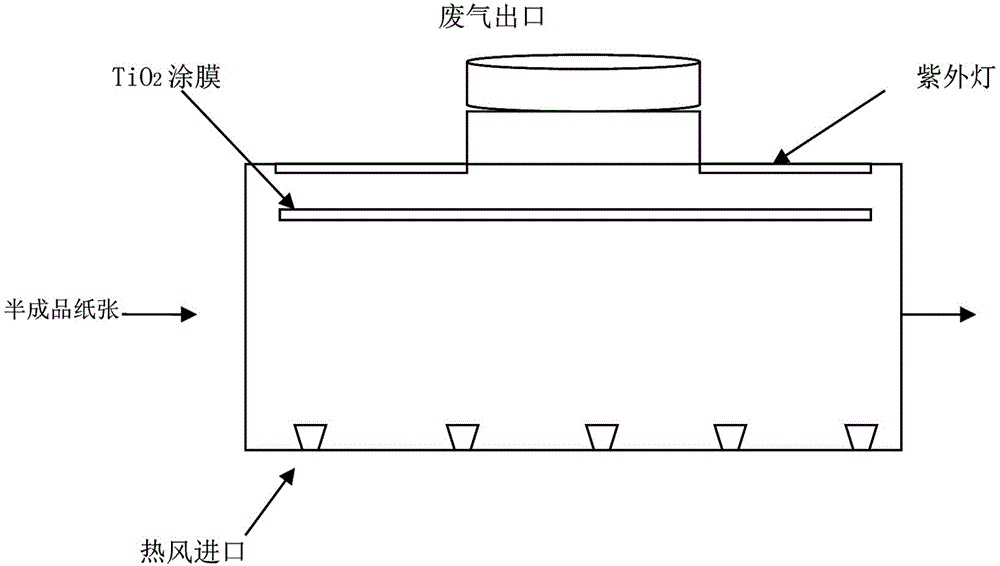

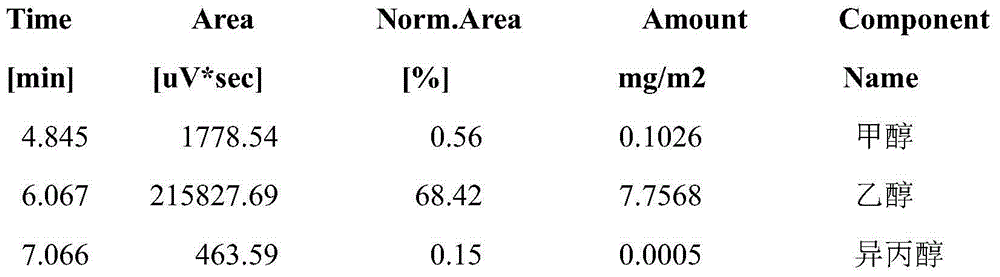

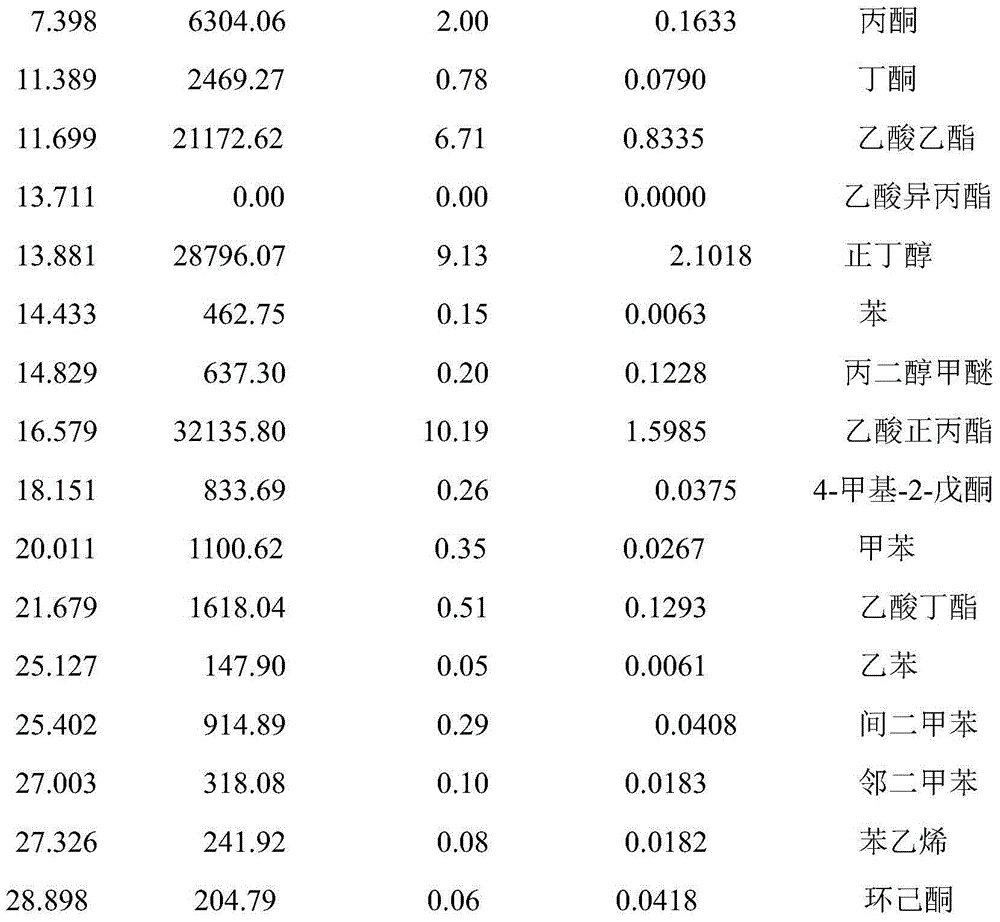

[0018] A method for producing aluminum-coated paper with qualified formaldehyde and / or TVOC content, comprising the following steps, 1) detection result of aluminum-coated paper to be treated: formaldehyde exceeds the standard, the standard is 20.00 mg / kg, the actual content is 35.00 mg / kg, and benzene exceeds the standard , the standard is 0.002mg / ㎡, the actual content is 0.006mg / ㎡, the aluminized paper enters the photocatalytic reactor, the running speed is 100m / min, 2) the hot air is turned on, the temperature reaches 120-130℃, the exhaust rate is greater than 30%, formaldehyde and TVOC substances are volatilized from the aluminum-coated paper, 3) two UV lamps are fully turned on, the mixed gas containing formaldehyde and TVOC is mixed with the nano-La modified TiO sprayed on the rotating rod 2 Space contact (the aforementioned nano-La modified TiO 2 Mix with soluble starch solution at a mass ratio of 1:20), react under the acceleration of ultraviolet light with a wavelengt...

Embodiment 2

[0030] The steps are the same as in Example 1, and the photocatalytic reagent is TiO2 modified by Bi. Experiments have found that the degradation rate of formaldehyde reaches 88.5%, and the degradation rate of benzene reaches 73.2%, which meets the limit of volatile organic compounds in cigarette sticks and box wrapping paper. "Provisions.

Embodiment 3

[0032] The steps are the same as in Example 1, and the photocatalytic reagent is Nb-modified TiO2. Experiments have found that the degradation rate of formaldehyde reaches 92.3%, and the degradation rate of benzene reaches 76.6%, which meets the limit of volatile organic compounds in cigarette rods and box wrapping paper. "Provisions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com