Mineral processing process of copper sulphide ores containing high-grade native copper

A natural copper and process technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve problems affecting production operation, damage to crushing equipment, adhesion, etc., achieve good beneficiation process indicators, and be conducive to gravity separation Homework, the effect of improving the efficiency of grading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

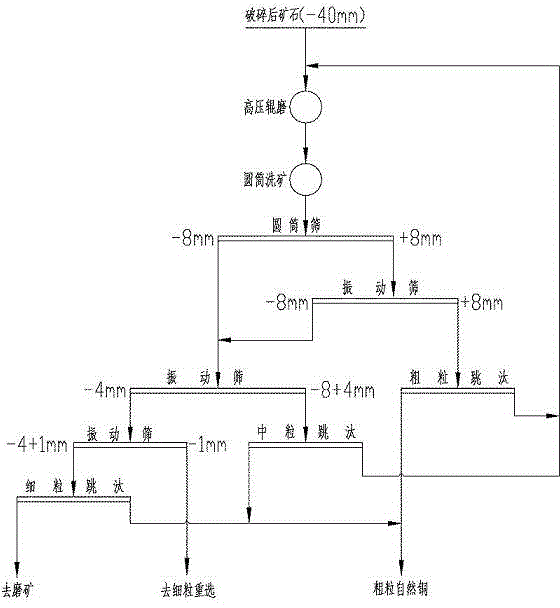

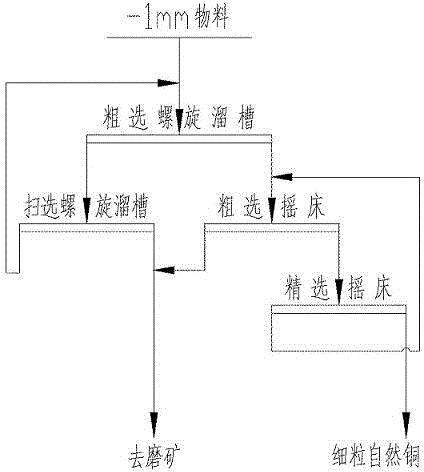

[0016] The beneficiation process of high-grade natural copper-containing copper sulfide copper ore of the present invention comprises the crushing and recovery process system of large natural copper, the crushing process system before gravity separation, the gravity separation recovery process system of coarse-grained natural copper, the fine-grained natural copper The natural copper gravity recovery process system is composed of the natural copper gravity recovery process system and the copper sulfide ore recovery process system. The specific implementation process is as follows:

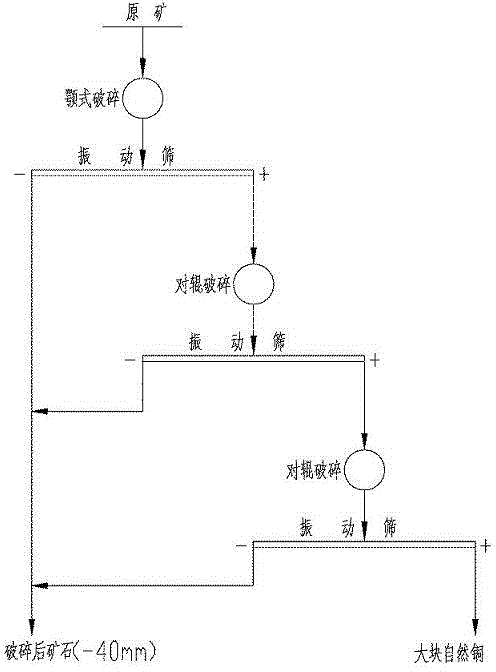

[0017] 1. Crushing and recovery of large pieces of natural copper: the raw ore is firstly crushed by the first jaw crusher, and the ore after jaw crushing is sent to the grading screen through the belt, and the -40mm ore under the screen is the crushed qualified ore, which is fed into the sieve. The second stage crushes the roller crusher. After crushing, the ore is fed to the third stage pre-crushi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com