Flexible automatic distributing device for shaft sleeve workpieces

A material distribution device and workpiece technology, applied in metal processing and other directions, can solve problems such as difficulty in completing order tasks on time, rising manufacturing costs, labor recruitment and management difficulties, etc., to alleviate labor recruitment and management difficulties, improve utilization, and improve product quality. and productivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

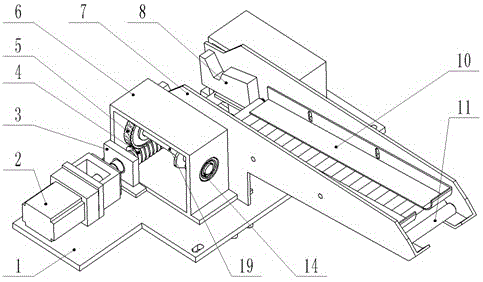

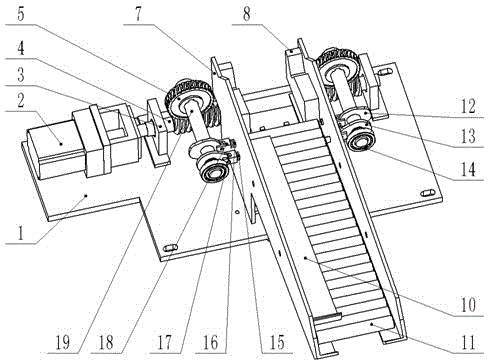

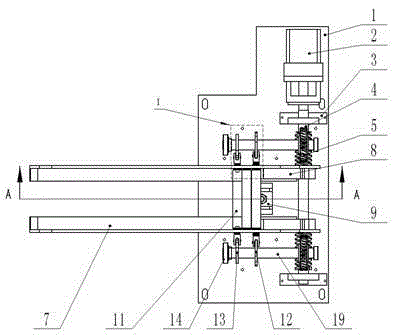

[0030] The present invention will be further described below in conjunction with accompanying drawings and examples.

[0031] Such as figure 1 , figure 2 as well as image 3 As shown, the present invention includes a flexible material storage mechanism, a servo material distribution mechanism and a pneumatic pushing mechanism arranged below the servo material distribution mechanism; wherein:

[0032] Flexible material storage mechanism: including two L-shaped silo baffles 7 and two limiting plates 10; the two limiting plates 10 are respectively fixed on the inner sides of the two L-shaped silo baffles 7 along the length direction, forming a In the inclined space for accommodating shaft sleeve workpieces 11, two fixing frames 8 are respectively fixed on the tail ends of the two silo baffles 7, and the positions can be moved relative to the slideways. The positions of the two limiting plates 10 can be adjusted up and down along the inner sides of the two L-shaped silo baffle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com