Quick early warning method of in-furnace tension fluctuation of cold rolled production line

A technology of production line and tension, applied in the direction of metal rolling, metal rolling, and keeping roll equipment in an effective state, can solve problems such as production instability and broken belts, reduce human factors, reduce broken belts, and speed up early warning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

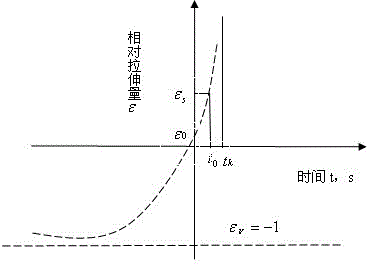

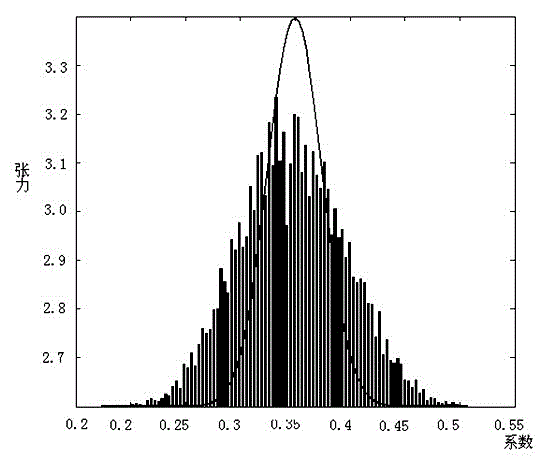

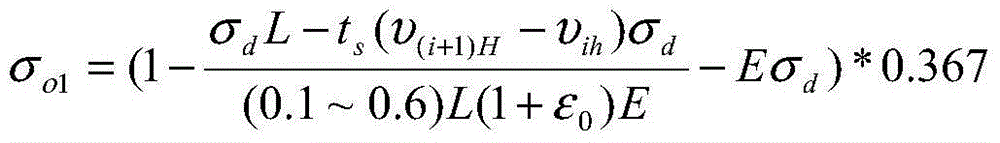

[0016] See figure 1 with figure 2 , a method for rapid early warning of tension in a cold rolling production line furnace of the present invention includes

[0017] 1. Tension setting model formation

[0018] The on-site tension setting model of the unit is based on the common sense analysis of tension setting plus the regression of measured data. According to common sense, the main factors affecting the set tension of the strip are: the thickness, width and speed of the strip. Since the speed factor has been compensated in the electrical control, it will not be considered here. The relationship between strip tension and thickness and width can generally be described as: the wider and thicker the strip, the greater the tension. Its mathematical expression is:

[0019] T=α+β×(Th×Wd) (1)

[0020] Among them: T is tension [N], Th is thickness [μm], Wd is width [mm], α, β are coefficients. Analyzing field data. According to the convention of tension setting, it is general...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com