Quenching rolling micro-tension control system and method for steel rail

A micro-tension control and rolling force technology, applied in the direction of tension/pressure control, metal rolling, temperature control, etc., can solve the problems of undetectable tension, damage to the size and contour of metal products, and changes in the thickness of rolled pieces, so as to avoid The effect of reheating the rail, reducing the geometric dimension out-of-tolerance, and meeting the quenching requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In the following, the present invention will be specifically described through exemplary embodiments. It should be understood, however, that elements, structures and characteristics of one embodiment may be beneficially incorporated in other embodiments without further recitation.

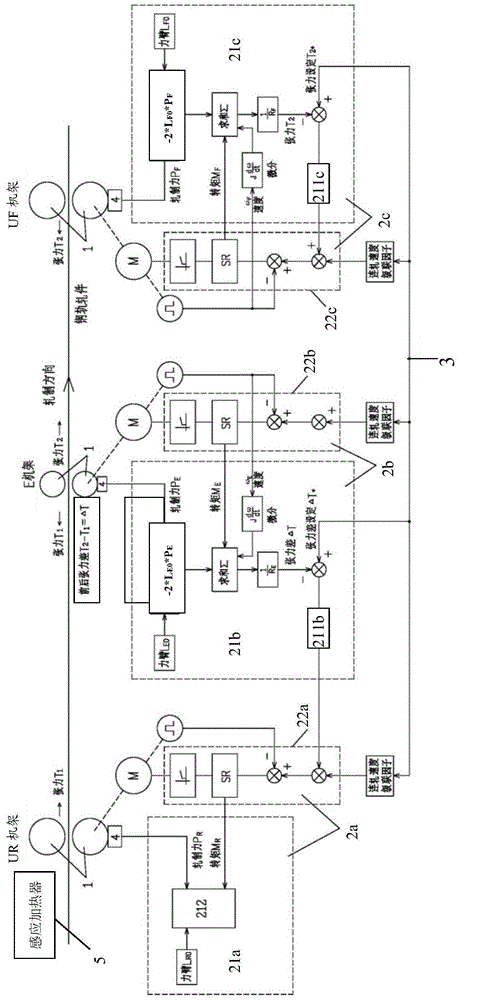

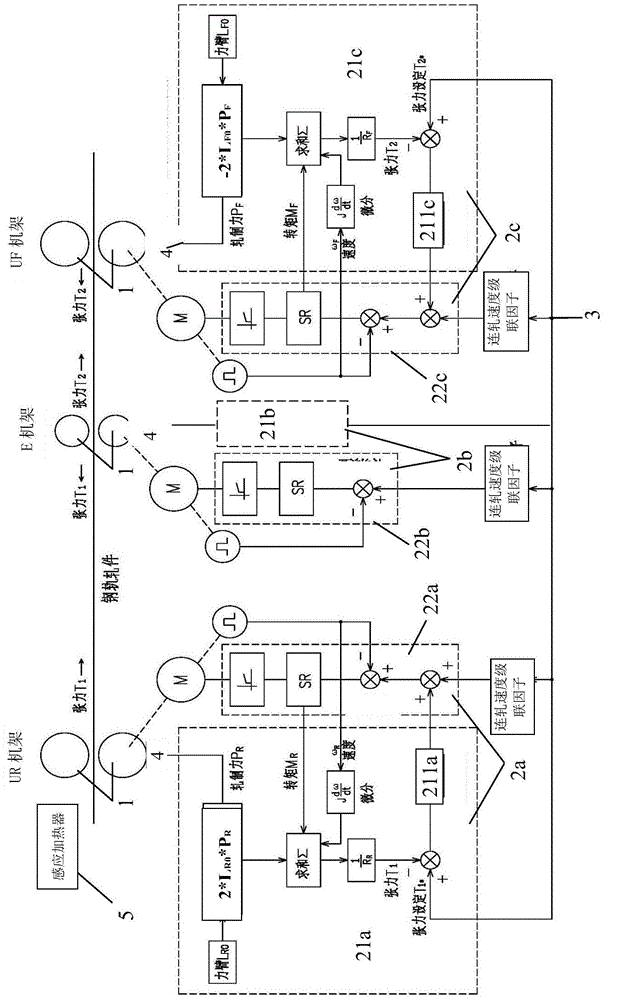

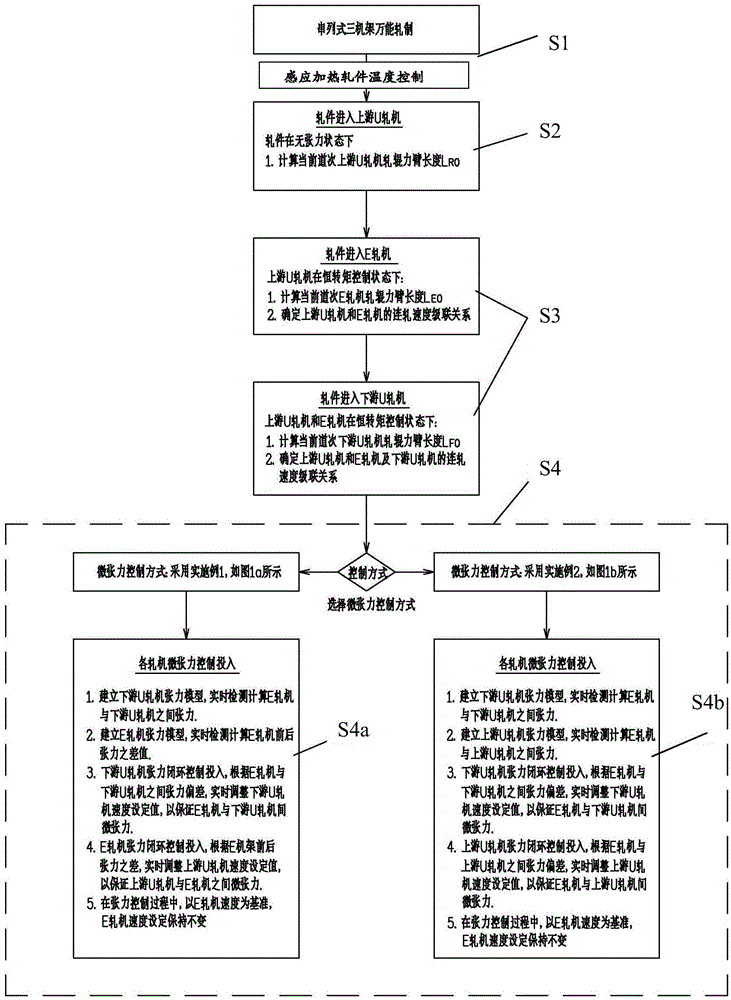

[0044] The micro-tension control system and method of the present invention are mainly aimed at the tandem universal rolling of section steel production, especially the rolling of high-speed steel rails. The tandem universal rolling mill is generally composed of a plurality of racks arranged in the order in which the rolled pieces enter. is the downstream rack of the rack that passes first. Such as Figure 1a and 1b As shown, these stands are divided into U stands and E stands. Since the tandem universal rolling mill is a reversible continuous rolling production line, the U stand upstream of the E stand becomes Becomes the downstream U rack of the E rack. Among them, the U frame includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com