Aluminum billet casting machine

A pouring machine and aluminum blank technology, which is applied to equipment for feeding molten metal into molds, metal processing equipment, casting equipment, etc., can solve problems such as low efficiency, product quality, hidden dangers to personal safety, and high labor intensity, and achieve improved Improve production efficiency and product quality, reduce personal safety hazards, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

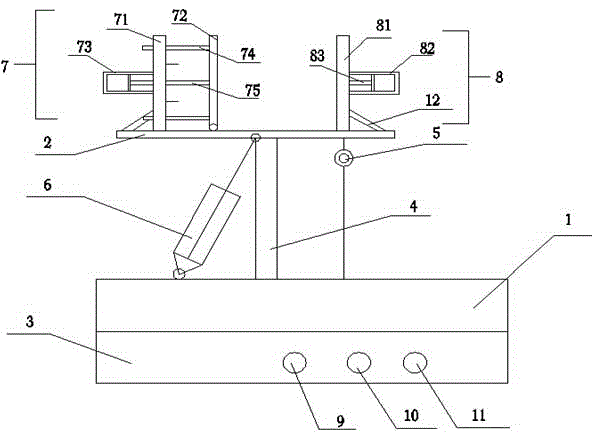

[0014] figure 1 The specific embodiment of the present invention is shown: an aluminum blank pouring machine, including a rubber vulcanizing machine base 1 and a workbench 2, characterized in that: the lower end of the rubber vulcanizing machine base 1 is provided with an oil tank 3, and the rubber vulcanizing machine base 1 is provided with a supporting column 4 and an overturning column 5, the workbench 2 is set on the support column 4 and hinged with the overturning column 5, and an overturning oil cylinder 6 is provided between the workbench 2 and the base 1 of the rubber vulcanizing machine. Turning oil cylinder 6 is hinged with workbench 2 and rubber vulcanizer base 1 respectively, and described turnover oil cylinder 6 is connected with oil tank 3, and described workbench 2 is provided with movable die device 7 at one end, and fixed die device 8 at the other end.

[0015] In this embodiment, the movable mold device 7 includes an oil cylinder fixed plate 71, a movable mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com