Continuous automatic sawing method for piston blank pouring riser

A technology for pouring risers and blanks, which is applied in the field of continuous automatic sawing machine tools for pouring and rising of piston blanks, can solve the problems of long adjustment time, high labor intensity, and low overall efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

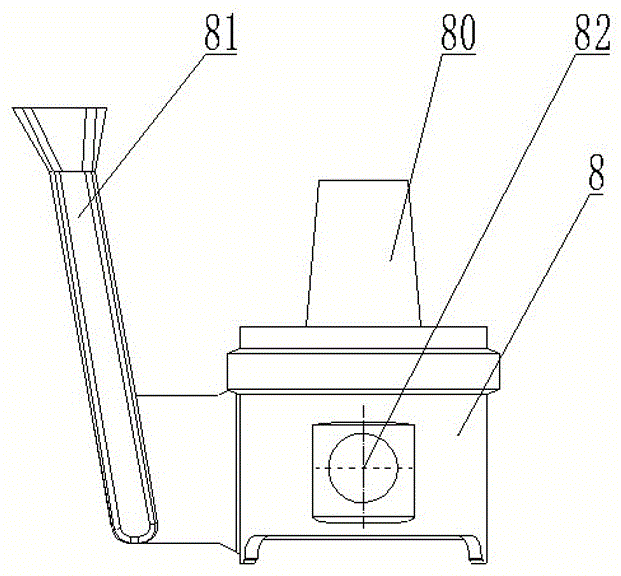

[0026] Such as image 3 It can be seen that the piston blank 8 provided by the casting process includes a top riser 80 and a side runner 81, and the piston blank 8 is processed with a pin hole 82. The continuous automatic sawing machine tool for the piston blank pouring riser provided by the present invention is used for Cut off the top riser 80 and the side runner 81.

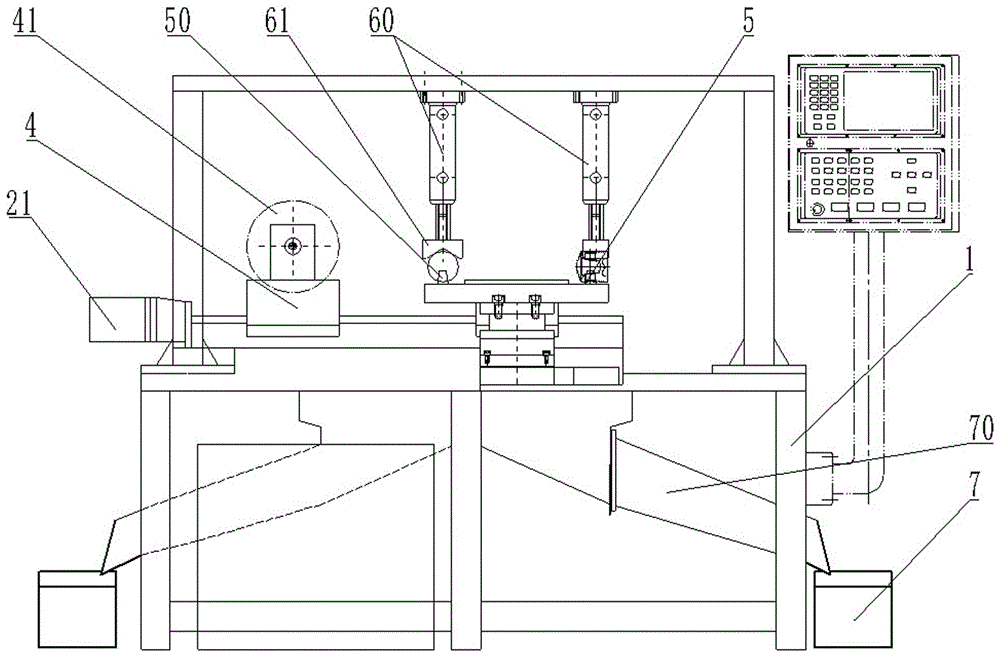

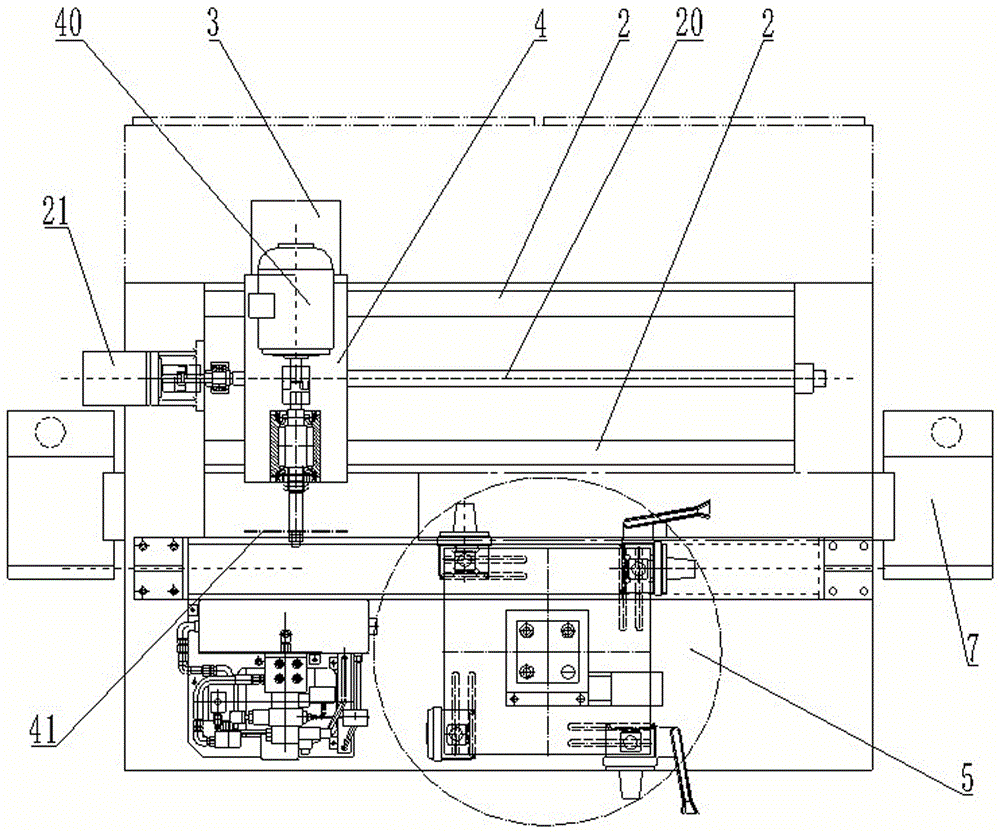

[0027] Such as figure 1 , figure 2 It can be seen that the continuous automatic sawing machine tool for pouring the piston blank into the riser of the present invention includes a bed body 1, the bed body 1 is provided with a Z-direction traveling device, and an X-direction traveling device 3 is movable on the Z-direction traveling device , the X-direction walking device 3 is movable to be provided with a cutting motor carriage 4, the cutting motor carriage 4 is provided with a cutting motor 40, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com