Composite punching equipment of inner lining of refrigerator

A refrigerator liner and punching technology, which is applied in metal processing and other directions, can solve the problems of reducing enterprise work efficiency, increasing energy consumption, and increasing enterprise production costs, so as to achieve high equipment cost investment, reduce production energy consumption, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

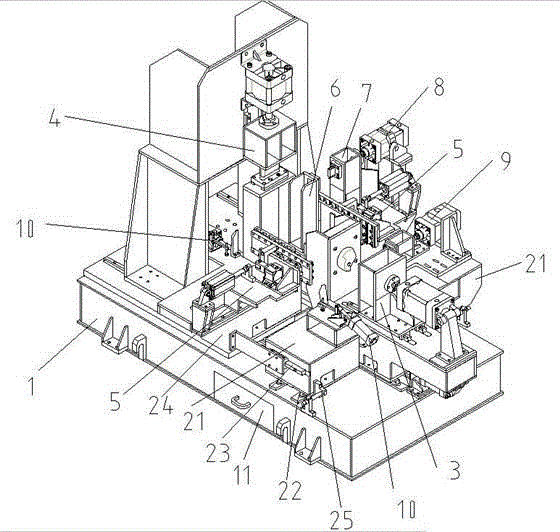

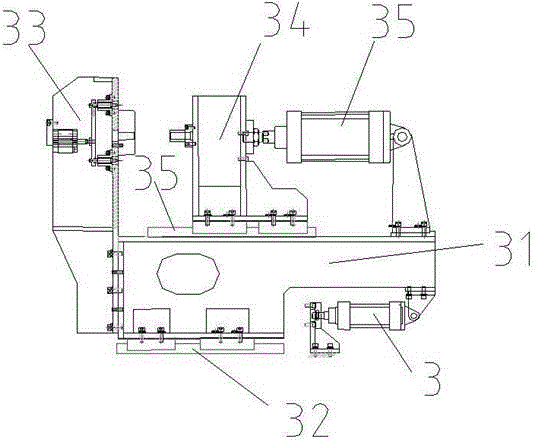

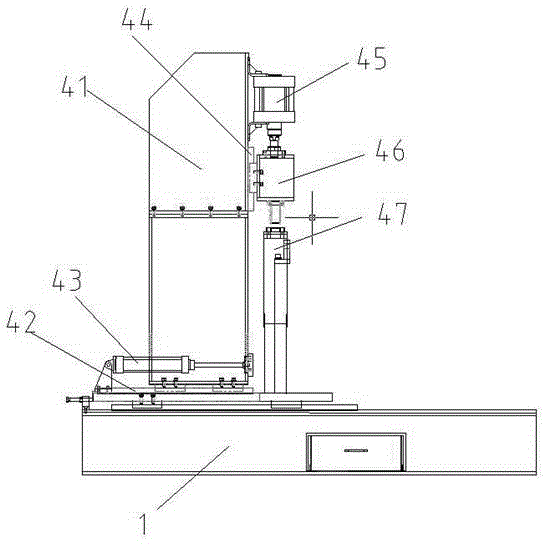

[0028] like Figures 1 to 7 As shown, a composite punching device for a refrigerator liner includes a base 1, two width adjustment platforms are symmetrically arranged on the base 1, and a back punching assembly 4 and a ceiling lamp punching assembly 3 are arranged in sequence between the two width adjustment platforms , the upper parts of the two width adjustment platforms are respectively provided with a side air hole punching mechanism 5, and the two side air hole punching mechanisms 5 are symmetrically arranged, and one side of the side air hole punching mechanism 5 on one of the width adjustment platforms is set There is a light switch punching assembly 9, and a temperature sensor punching assembly provided on the other side;

[0029] The above-mentioned side ventilation hole punching mechanism 5 includes a punching assembly, a driving assembly for driving the punching assembly to punch holes, and a supporting assembly for setting off the side wall of the refrigerator lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com