Material output device of 3D color printer

A 3D printer and output device technology, used in the field of color 3D printer material output devices, can solve the problems of providing pressure power for materials that cannot be melted, the uniformity of molten products, poor stability, and the inability to print colorful models. Good heating and extrusion uniformity, high assembly accuracy, and the effect of reducing current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

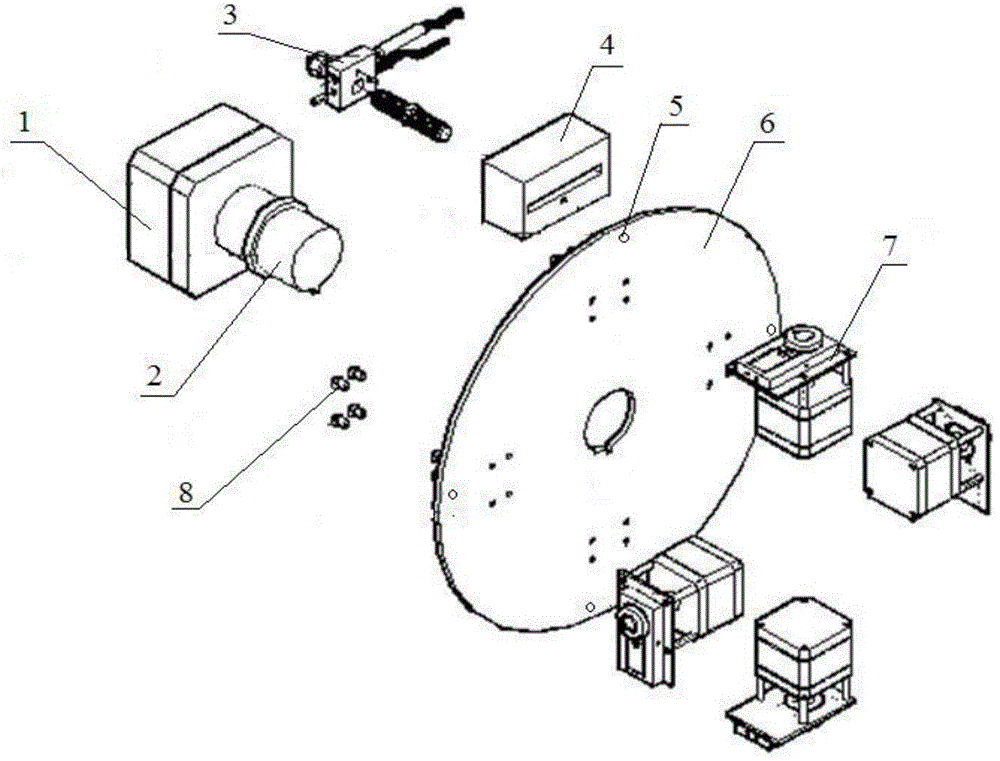

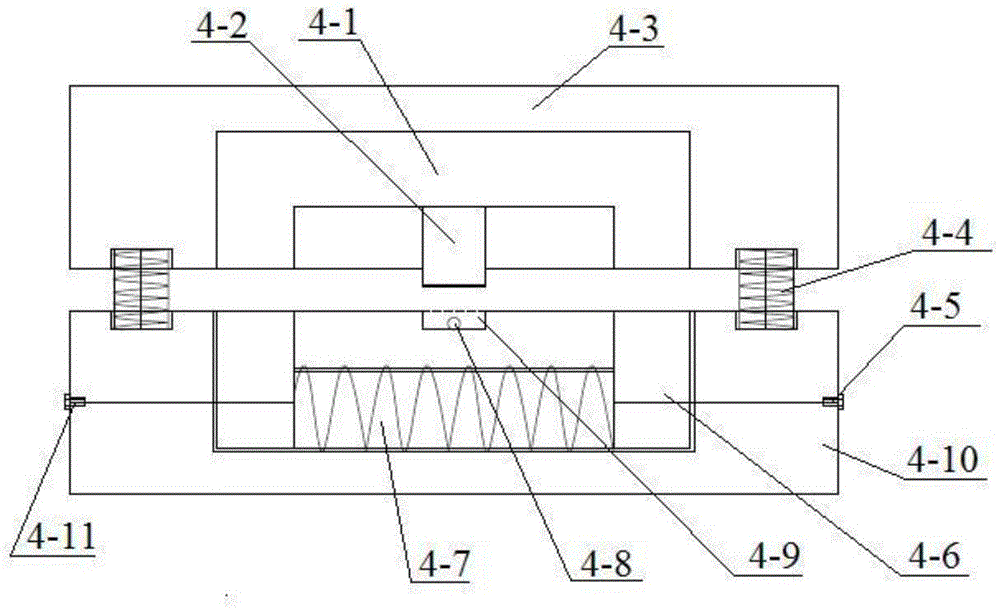

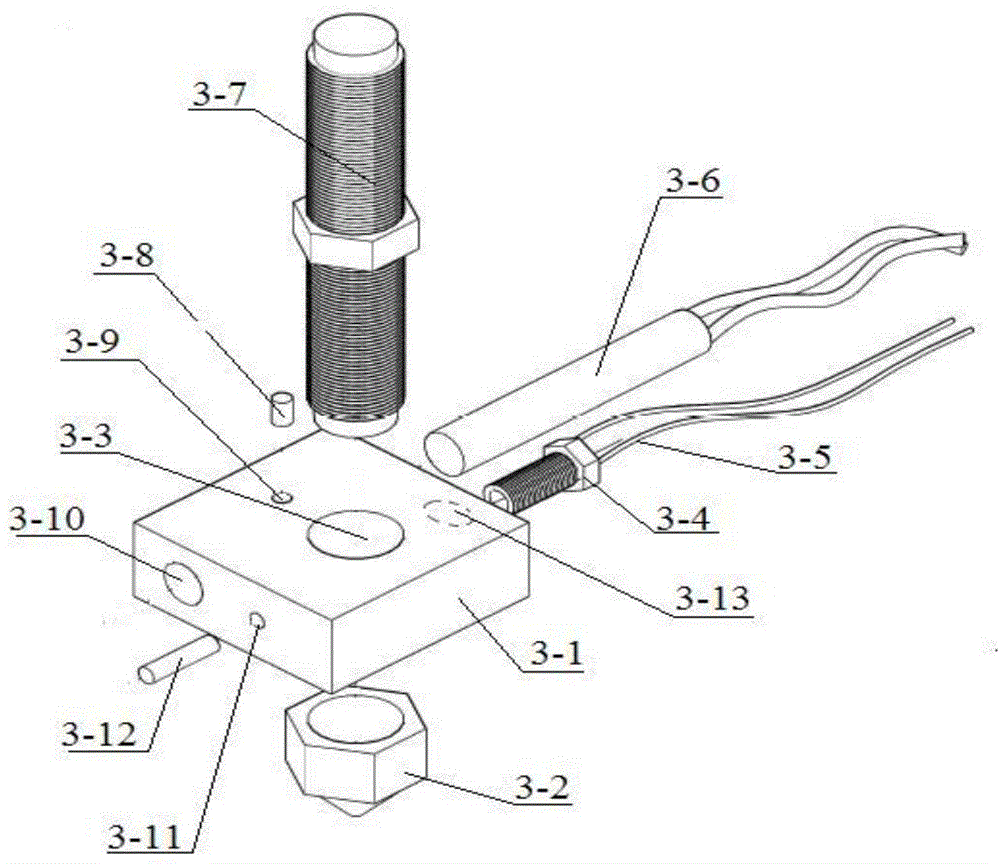

[0023] Such as figure 1 The shown material output device of a color 3D printer includes a turntable motor 1 and a motor shaft 2, the cutting assembly 4 is fixedly installed on the motor shaft 2, and a material through hole 1 is opened on the color conversion disc 6. 5. A cut-off assembly 4 is installed at the material passage hole 1 on the side of the color conversion disk 6 close to the motor, and a thermal fusion assembly 3 is fixedly installed on the cut-off assembly 4. The material passage hole located on the other side of the color conversion disk 6 Extruder device 7 is installed at 5 places; figure 2 The cut-off assembly 4 shown includes a moving contact housing 4-3, a static contact housing 4-10, and a return spring 4-4 for connecting the moving contact housing 4-3 and the static contact housing 4-10. An electromagnet moving contact 4-1 is installed in the moving contact shell 4-3, a cutter 4-2 is installed on the electromagnet moving contact 4-1, and a The cutter ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap