Blackboard eraser cleaning device

A cleaning device and a blackboard eraser technology, applied in the field of teaching appliances, can solve the problems of flying dust, health hazards of teachers and students, and excessive dust, and achieve the effects of improving collection efficiency, avoiding secondary pollution, and ensuring the teaching environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

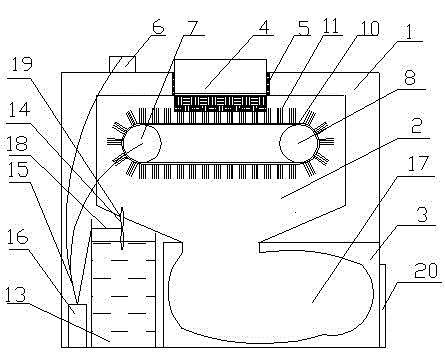

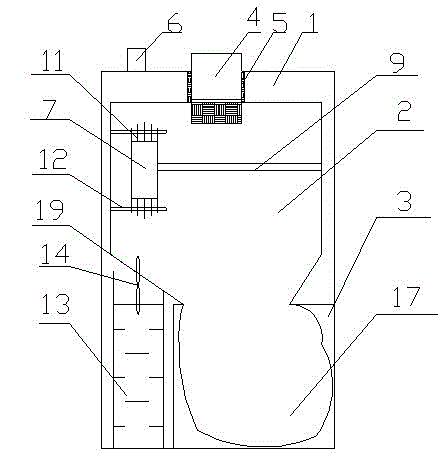

[0015] see Figure 1-2 , a blackboard eraser cleaning device, comprising a box body 1, a dust treatment chamber 2 and a dust collection chamber 3, the dust treatment chamber 2 and the dust collection chamber 3 are installed inside the box body 1, the middle part of the box body 1 top An eraser placement port 4 is provided, and the side walls of the eraser placement port 4 are provided with sealing gaskets 5, and a control switch 6 is provided on the box 1 on the left side of the eraser placement port 4, and the lower end of the dust processing chamber 2 is connected to the dust collection chamber. The upper end of 3 is connected, and a dust treatment device is provided in the dust treatment chamber 2. The dust treatment device includes a driving wheel 7, a driven wheel 8 and a belt 10, and the driving wheel 7 and the driven wheel 8 are fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com