An automatic lifting control system of a large coal belt conveyor

An automatic lifting and control system technology, which is applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as failure to achieve expected goals in a timely and effective manner, lump coal wear, belt damage, etc., to reduce labor intensity and improve The lump carbon rate and the effect of reducing misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

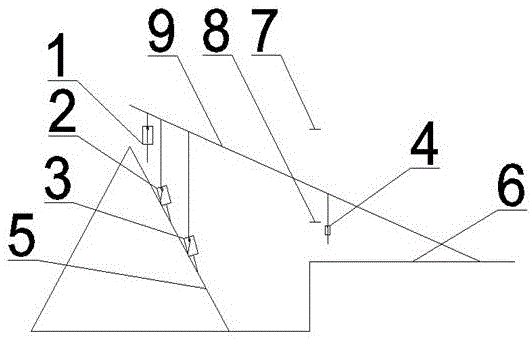

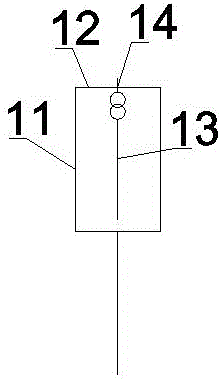

[0010] An automatic lifting control system for a large lump coal belt includes a lifting mechanism matched with the head of the belt conveyor, an electric drive device and a control device for the lifting mechanism of the head of the belt conveyor, and is characterized in that four belt conveyor heads are installed at the head position. Check the grounding switch device and a high limit switch and a low limit switch, when the belt conveyor head 9 with coal face 5 The distance is greater than 80cm, detect the grounding switch device two and three dangling , Detect that the grounding switch device two and three are disconnected, the time relay is closed, the electric drive device drives the lifting mechanism to run, and the belt conveyor head 9 down; when the belt conveyor head 9 Descending stage, detection of earthing switchgear Four Touch the operating platform to detect the grounding switch device Four On, belt conveyor head 9 Stop descending, or belt conveyor head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com