Spinning cake pushing device

A silk cake and lead screw technology, applied in the field of chemical fiber filament automatic unwinding machine, can solve problems such as unfavorable support arms and high rigidity requirements, and achieve the effects of external simplicity, simplification of the mechanism, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

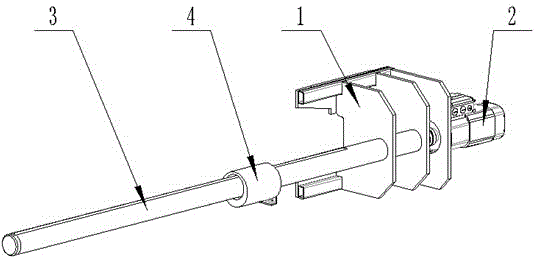

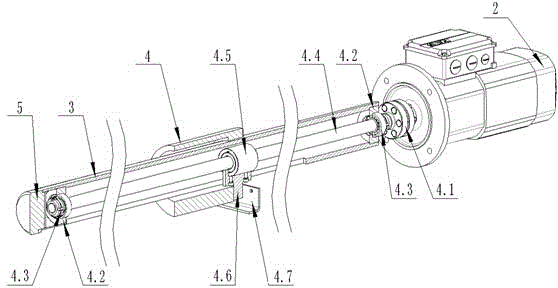

[0013] Example : a kind of pushing wire cake device, such as figure 1 , 2 As shown, it includes a bracket 1, a motor 2, a support arm 3, a lead screw 4.4, a lead screw nut 4.5 compatible with the lead screw 4.4, and a cake pusher 4. One side of the support 1 is provided with a motor 2, and the support arm 3 One end is fixed on the bracket 1, and the other end is provided with a plug 5. The support arm 3 of the cylinder is a hollow structure, and a lead screw 4.4 driven by the motor 2 through the coupling 4.1 runs through the inside, and the two ends of the lead screw 4.4 are passed through the counter. The two bearings 4.3 in the direction are installed in the bearing seat 4.2 in the support arm 3, and the leading screw nut 4.5 that is suitable is installed on the leading screw 4.4. The cake pushing head 4 is set on the outside of the support arm 3, and it is a cylindrical mating surface with the support arm 3. The support arm 3 is provided with a guide groove along the axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com