Method for modifying properties of graphene

An adjustment method and graphene technology, applied in chemical instruments and methods, inorganic chemistry, electrical components, etc., can solve the problems of graphene film damage, semiconductor film structure damage, inappropriate semiconductor characteristic adjustment methods, etc., to simplify the manufacturing process, The effect of reducing industrial costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

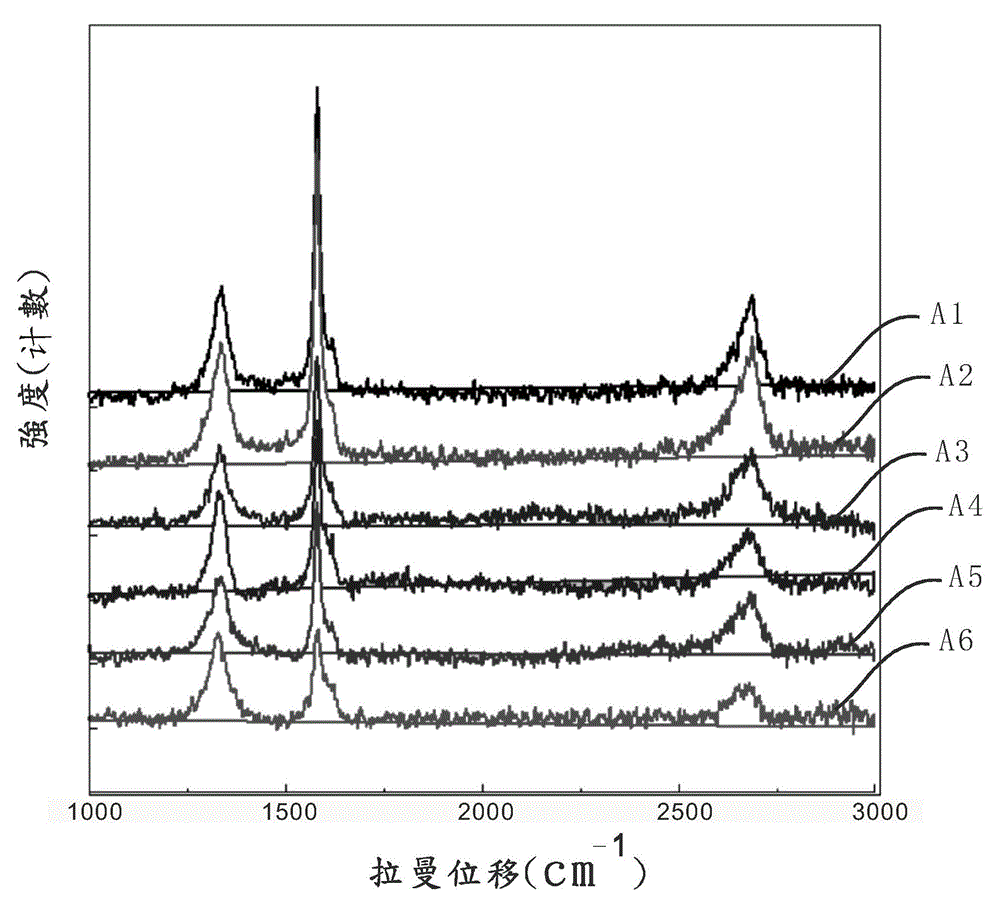

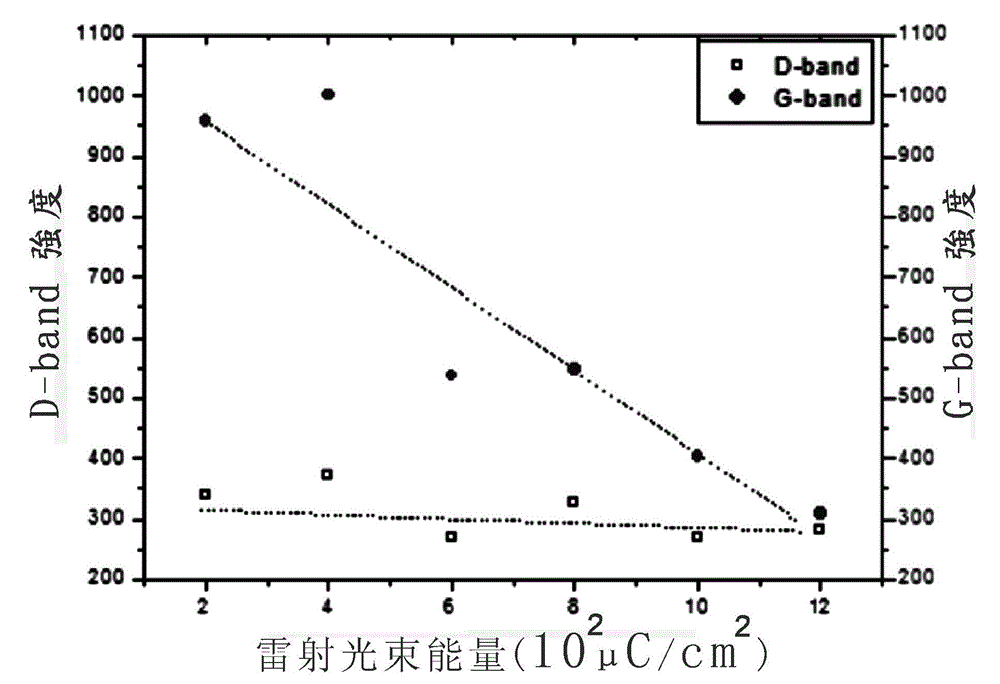

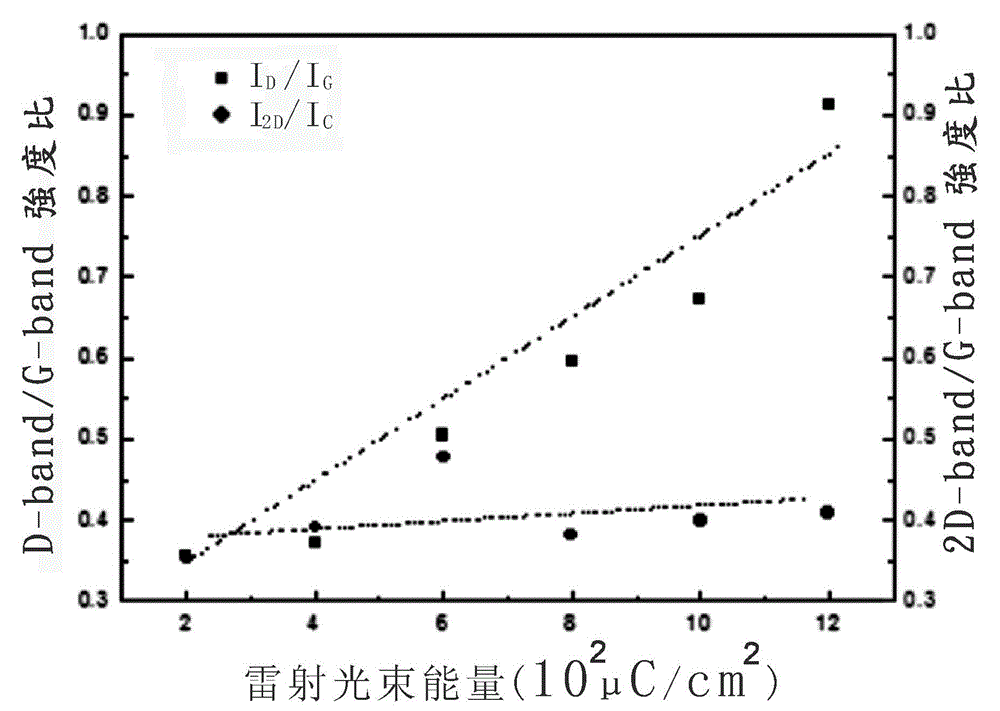

[0021] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

[0022] The graphene characteristic adjustment method of the present invention includes: a graphene film providing step and a modifying step to obtain a graphene material.

[0023] In detail, the graphene film providing step is to provide a graphene film, which is formed on a substrate, wherein the substrate can be the surface of an electronic component or transistor to which the graphene is to be attached, and its material can be Silicon, glass or plastic, without limitation.

[0024] Graphene can be formed on the substrate by any means, for example, it can be formed on the substrate by chemical vapor deposition, physical vapor deposition or mechanical stripping. The above-mentioned methods are common methods in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com