Circulating cooling water sterilizing method and application

A technology of circulating cooling water and circulating water cooling, applied in chemical instruments and methods, sterilization/microdynamic water/sewage treatment, natural water treatment, etc., can solve the problem of increasing power consumption, reducing current efficiency, increasing periodic reversal The frequency of electrode polarity and other issues can ensure the life of the electrode and avoid the reduction of electrolytic current efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment is used to illustrate the sterilization method of circulating cooling water of the present invention.

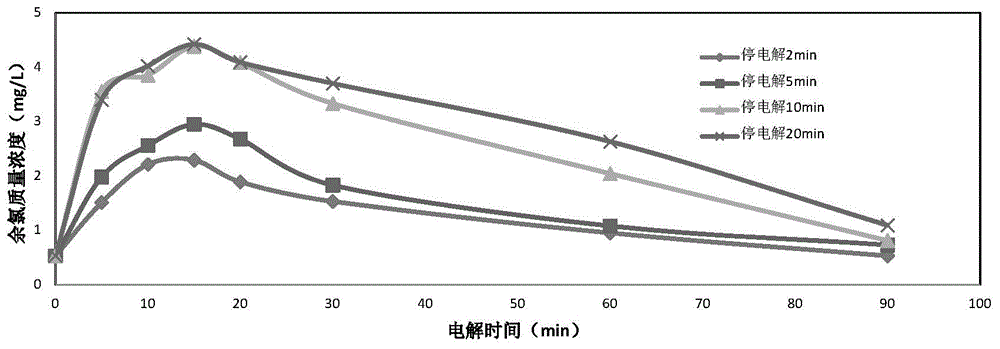

[0052] Test water quality and electrolysis device as in Comparative Example 1, adjust the flow rate of circulating water entering the electrolysis device to 4.0m through a flow meter 3 / h, after electrolysis for 1.5h, stop electrolysis for 2min, 5min, 10min and 20min respectively, then continue electrolysis for 1.5h, investigate the change of residual chlorine mass concentration in circulating water after different time of electrolysis and continue electrolysis, the specific data are as follows image 3 shown. image 3 Indicates the changes in the mass concentration of residual chlorine in the outlet circulating water after 1.5 hours of electrolysis and after the electrolysis was stopped for 2 minutes, 5 minutes, 10 minutes and 20 minutes and then the electrolysis was continued.

[0053] from image 3 It can be seen from the data in the figure that t...

Embodiment 2

[0055] This embodiment is used to illustrate the sterilization method of circulating cooling water of the present invention.

[0056] Test water quality and electrolysis device as in Comparative Example 1, adjust the flow rate of circulating water entering the electrolysis device to 4.0m through a flow meter 3 / h, according to the electrolysis 20min, electrolysis 10min periodical operation, continuous operation 10h, investigate the change of residual chlorine mass concentration in the circulating water at the outlet of the electrolysis device. Specific data such as Figure 4 shown. Figure 4 Indicates: 5min, 10min, 15min of each periodic operation (the mass concentration of residual chlorine reaches the maximum value of about 4.6mg / L), 20min, 25min, and 30min (the mass concentration of residual chlorine drops to about 0.19mg / L). The mass concentration of residual chlorine in the outlet circulating water.

[0057] from Figure 4 It can be seen from the data in that, accordi...

Embodiment 3

[0059] This embodiment is used to illustrate the sterilization method of circulating cooling water of the present invention.

[0060] Test water quality and electrolysis device as in comparative example 1, adjust the flow rate of circulating water entering the electrolysis device to 2.4m through a flow meter 3 / h, according to the electrolysis 20min, electrolysis 10min periodical operation, continuous operation 10h, investigate the change of residual chlorine mass concentration in the circulating water at the outlet of the electrolysis device. Specific data such as Figure 5 shown. Figure 5 Indicates: 5min, 10min, 15min, 20min (mass concentration of residual chlorine reaches the maximum value of about 5.4mg / L), 25min, 30min (mass concentration of residual chlorine drops to about 0.29mg / L) of each periodic operation. The mass concentration of residual chlorine in the outlet circulating water.

[0061] from Figure 5 It can be seen from the data in that, according to this c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com