Method and device for enabling optical fiber preforming bar to be butted with tail handle

A technology of optical fiber preform and docking device, which is applied in the direction of manufacturing tools and glass manufacturing equipment, etc. It can solve the problems of affecting the stress of the docking part, inapplicability, and difficulty in cutting the angle of the cylinder, and achieves smooth docking parts and simple implementation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

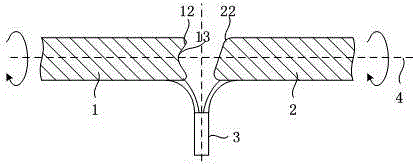

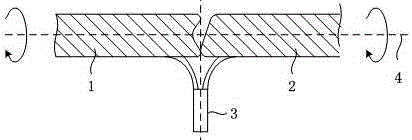

[0052] Example 1: Axial vapor deposition method (VAD) is used to deposit a powdery mandrel, and after dehydroxylation vitrification, a prefabricated rod with a diameter of 80 mm is formed. The preformed rod with a diameter of 80 mm is connected to a tail with a diameter of 80 mm by using the present invention. Handle for easy follow-up production.

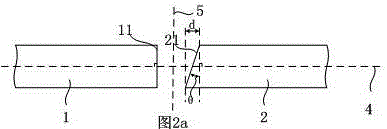

[0053] In this embodiment, θ is 5°, d=80*tan5°=7.00mm, D=2d / 3=4.67mm, according to Figure 2(a), use a cutting machine to cut the preform 1, so that the preform cut end face 11 and The axis 4 is vertical; use a cutting machine to cut the tail handle 2 so that the end face 21 forms an angle of 5° with the centerline 5 of the blowtorch.

[0054] The preform rod 1 and the tail handle 2 start to rotate at a speed of 10rpm, the blowtorch 3 is ignited and burned, and the H 2 The flow rate is 300L / min, the inner O 2 Flow rate is 50 L / min, external O 2 The flow rate is 100 L / min. After burning for 8 minutes, the preform master rod 1 and ...

Embodiment 2

[0057] Embodiment 2: Axial vapor deposition method (VAD) is used to deposit a powder core rod, and a preform rod with a diameter of 50 mm is generated through dehydration vitrification, and the preform rod with a diameter of 50 mm is connected to a tail with a diameter of 50 mm by using the present invention. Handle for easy follow-up production.

[0058] In this embodiment, θ is 8°, d=50*tan8°=7.03mm, D=2d / 3=4.69mm, according to Figure 2(a), use a cutting machine to cut the preform 1, so that the preform cut end face 11 and The axis 4 is vertical; use a cutting machine to cut the tail handle 2 so that the cut end face 21 of the tail handle forms an 8° angle with the centerline 5 of the blowtorch.

[0059] The preform rod 1 and the tail handle 2 start to rotate at a speed of 10rpm, the blowtorch 3 is ignited and burned, and the H 2 Flow rate is 250L / min, inner O 2 Flow rate is 40 L / min, external O 2 The flow rate is 85 L / min. After burning for 6 minutes, the preform master ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com