Eucommia ulmoide gum fractionation column and method for continuously fractionating eucommia ulmoide gum

The technology of eucommia gum and grading column is applied in the field of eucommia gum production, which can solve the problems of increasing the amount of precipitant, and achieve the effect of reducing the amount of use and improving the separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

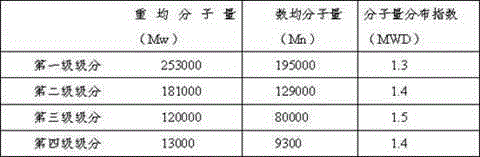

Embodiment 1

[0016] The extract of Eucommia ulmoides seeds produced in western Hunan was taken as raw material with benzene as the extraction solvent. The eucommia gum in the extract was directly classified.

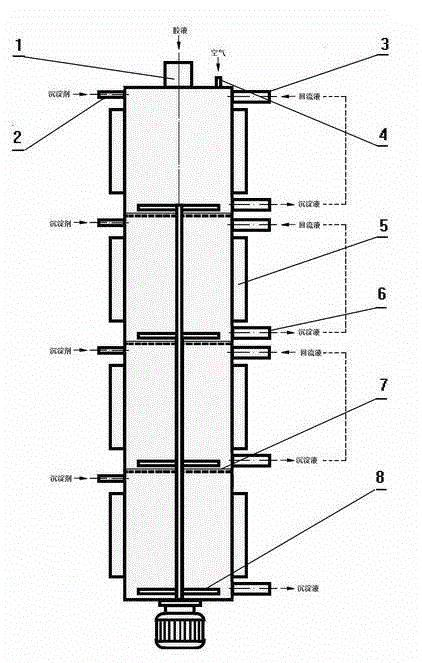

[0017] The eucommia glue classification device has a column height of 2.0 meters and a diameter of 25cm. It is divided into four stages, each stage is about 50cm high. The temperature of the first stage is controlled at 10°C, the second stage is controlled at 0°C, and the third stage is controlled at -5°C. The temperature of the fourth stage is controlled at -15°C, and the temperature control error is within 2°C; start stirring, and the stirring rate is controlled at 50~60 rpm

[0018] Pump the Eucommia gum extract from the upper inlet (1) of the classification column, the flow rate is between 60-120 L / h, preferably between 60-80 L / h, and open the first-stage precipitant inlet (2) , pump methanol as a precipitant, and the flow rate is controlled at 30~60 L / h. The flow rate ratio of t...

Embodiment 2

[0023] The extract of Eucommia ulmoides leaves in western Hunan was used as raw material, and the eucommia gum in the extract was directly classified. The weight average molecular weight before classification was 73,000, the molecular weight distribution index was 5.5, and the solvent of the extract was benzene.

[0024] The eucommia glue classification device has a column height of 2.0 meters and a diameter of 25cm. It is divided into four stages, each stage is about 50cm high. The temperature of the first stage is controlled at 10°C, the second stage is controlled at 0°C, and the third stage is controlled at -5°C. The temperature of the fourth stage is controlled at -15°C, and the temperature control error is within 2°C; start stirring, and the stirring rate is controlled at 60~80 rpm

[0025] Pump the Eucommia gum extract from the upper inlet (1) of the classification column, the flow rate is between 60-120 L / h, preferably between 60-80 L / h, and open the first-stage precipit...

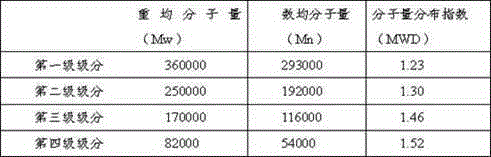

Embodiment 3

[0030] The bark extract of Eucommia ulmoides produced in western Hunan was used as a raw material, and the eucommia gum in the extract was directly classified. The weight average molecular weight before classification was 193000, and the molecular weight distribution index was 1.95. The extraction solvent is petroleum ether (boiling range 60~90°C).

[0031] The eucommia glue classification device has a column height of 2.0 meters and a diameter of 25cm. It is divided into four stages, each stage is about 50cm high. The temperature of the first stage is controlled at 10°C, the second stage is controlled at 0°C, and the third stage is controlled at -5°C. The temperature of the fourth stage is controlled at -15°C, and the temperature control error is within 2°C; the stirring is started, and the stirring rate is controlled at 90-100 rpm; the precipitating agent is ethanol.

[0032] Pump the Eucommia gum extract from the upper inlet (1) of the classification column, the flow rate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com