Low-warpage high-modulus modified polypropylene material and preparation method thereof

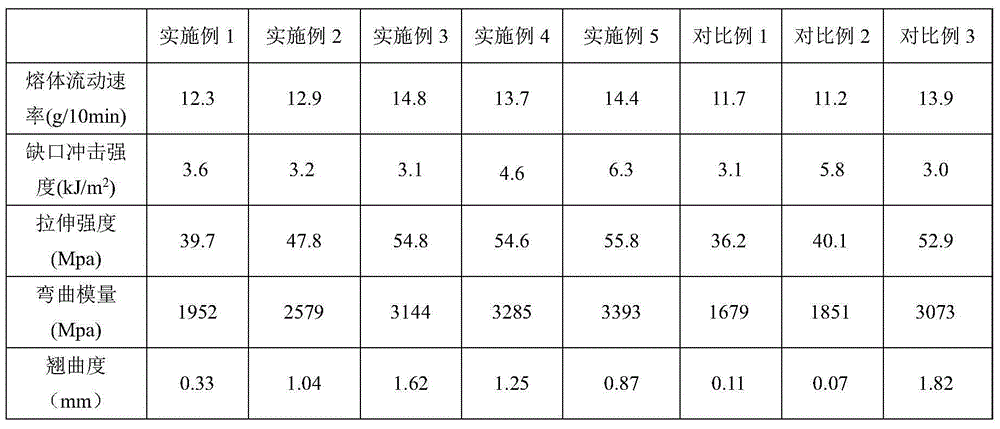

A polypropylene material and high modulus technology, applied in the field of modified polypropylene materials, can solve problems such as warping appearance, achieve the effects of improving warping resistance, good fluidity, and improving product warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

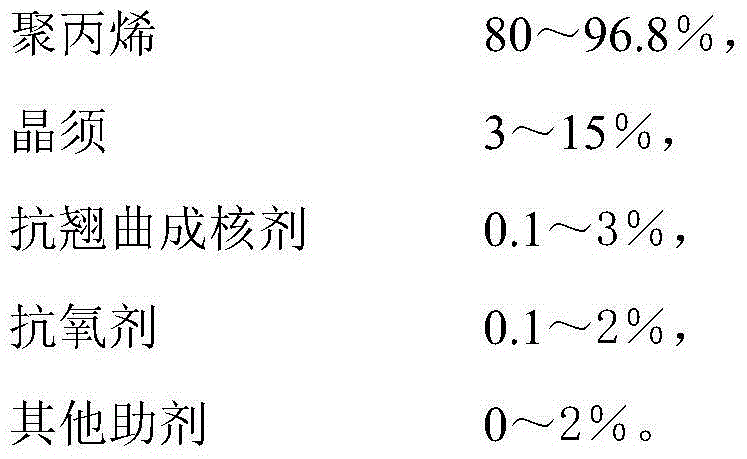

Method used

Image

Examples

Embodiment Construction

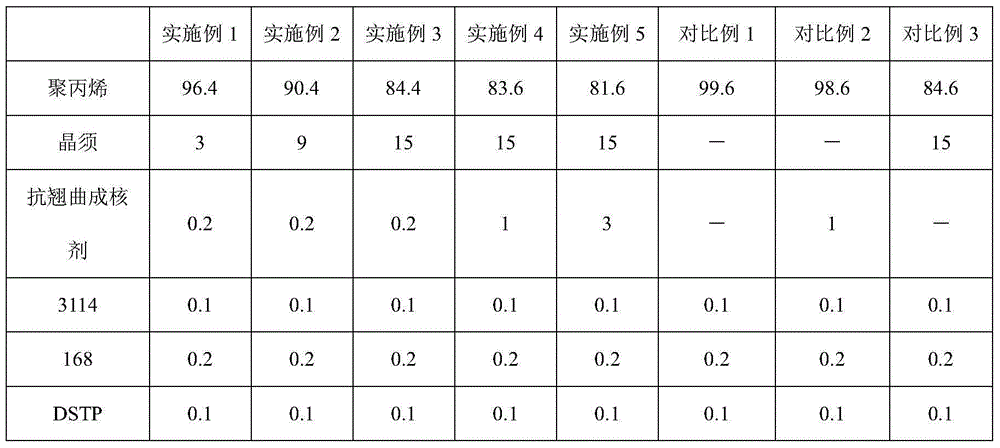

[0018] Below in conjunction with embodiment, the present invention is described in further detail.

[0019] In the composite material formulations of the examples and comparative examples, the polypropylene is a homopolypropylene produced by China Shanghai Petrochemical Co., Ltd., the trade name is M1200HS, and its melt flow rate is 11g / 10min (test conditions: 230 ° C × 2.16 Kg); Described whisker is produced by Feng Zhu Whisker Company, and trade name is NP-YW2, and its aspect ratio is at 30~40, and molecular formula is MgSO 4 5Mg(OH) 2 ·3H 2 O; described anti-warping nucleating agent is HPN-68L produced by Milliken Company, and its molecular formula is C 9 h 10 Na 2 o 4 The main antioxidant is selected from DSTP produced by British ICE company, whose chemical name is octadecyl thiodipropionate, and 3114 produced by Ciba company, whose chemical name is 3,5-di-tert-butyl-4-hydroxybenzyl phosphoric acid diethyl ester. The auxiliary antioxidant is 168 produced by Ciba Com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com