Method for synthesizing silibinin by virtue of enzyme catalysis reaction

A technology of catalytic reaction and silibinin, applied in the direction of fermentation, can solve problems such as long reaction time, and achieve the effects of rapid enzymatic reaction, simplification of cost, and improvement of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

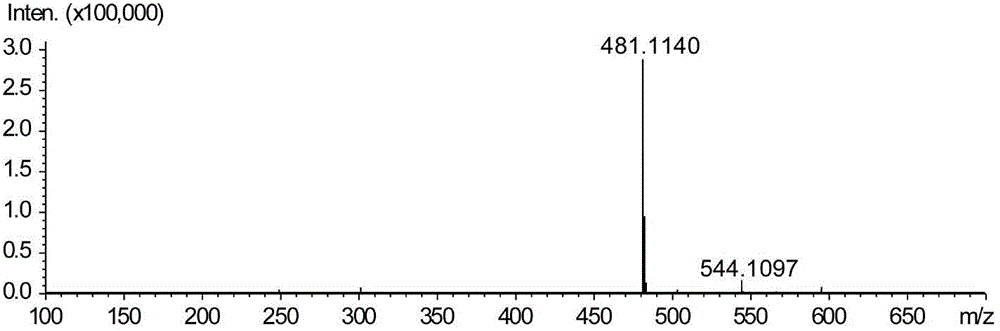

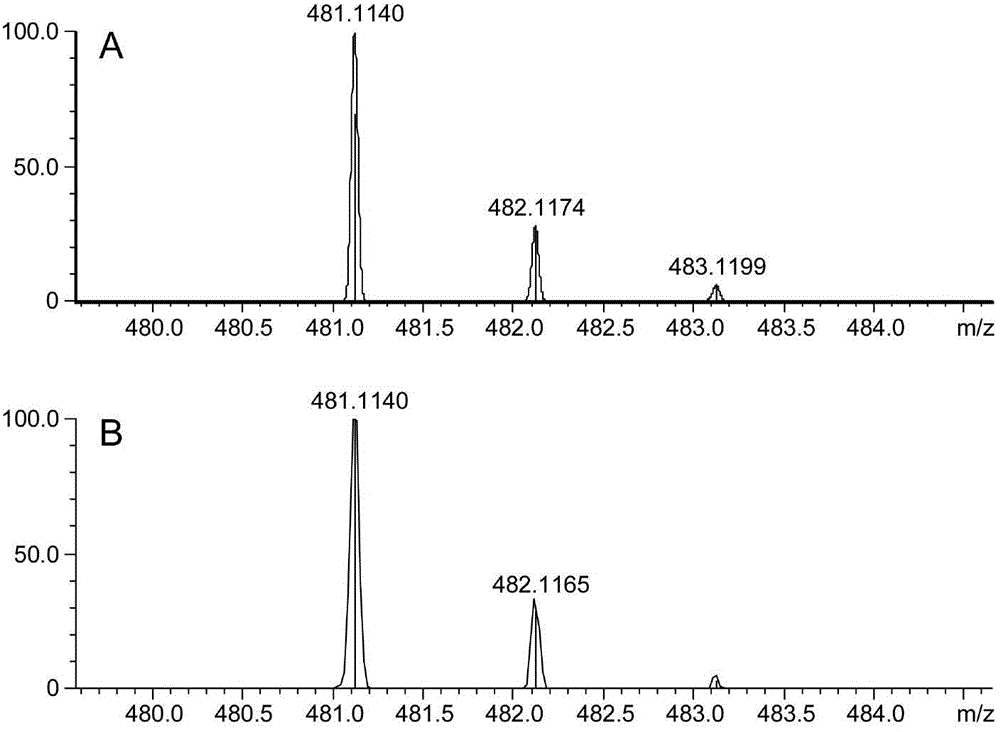

[0030] Example 1 Verification of peroxidase-catalyzed silibinin synthesis

[0031] In order to verify the ability of peroxidase to catalyze the synthesis of silibinin from coniferyl alcohol and docetaxel, coniferyl alcohol and docetaxel were used as substrates in H 2 o 2 In the presence of conditions, the synthesis of silibinin is catalyzed by horseradish peroxidase (HRP). It was verified that the omitted substrate, H 2 o 2 Or enzyme, the production of silybin, as shown in Table 1.

[0032] The chemical reaction formula of the synthetic reaction of silybin is as Figure 6 As shown, theoretically, one molecule of H is needed for every molecule of silybin synthesized 2 o 2 Participate in the reaction, when the molar ratio of coniferyl alcohol and docetaxel is 2:1, it is the optimum substrate ratio for the synthesis of silybin. In view of the fact that silibinin will be absorbed by the H in the reaction system at the same time 2 o 2 Therefore, we at first react under the...

Embodiment 2

[0039] Catalytic synthesis of silibinin under the insufficient condition of embodiment 2 hydrogen peroxide

[0040] In the presence of hydrogen peroxide, peroxidase can catalyze the synthesis of silibinin; at the same time, silybin can be decomposed by hydrogen peroxide in the reaction system. Therefore, the reaction is actually a dynamic equilibrium process. In this embodiment, the synthesis reaction of silibinin is carried out under the condition of insufficient hydrogen peroxide. Same as Example 1, react according to the conditions of molar ratio coniferyl alcohol:docetaxel=2:1, and insufficient hydrogen peroxide (about 45.3% of docuscetaxel), specifically as shown in table 2. All reactions were carried out 3 times and the average value was taken.

[0041] Table 2 Reaction system under the condition of insufficient hydrogen peroxide

[0042]

[0043] *MeOH is added after the reaction to terminate the enzymatic reaction.

[0044] We studied the change of silibinin pro...

Embodiment 3

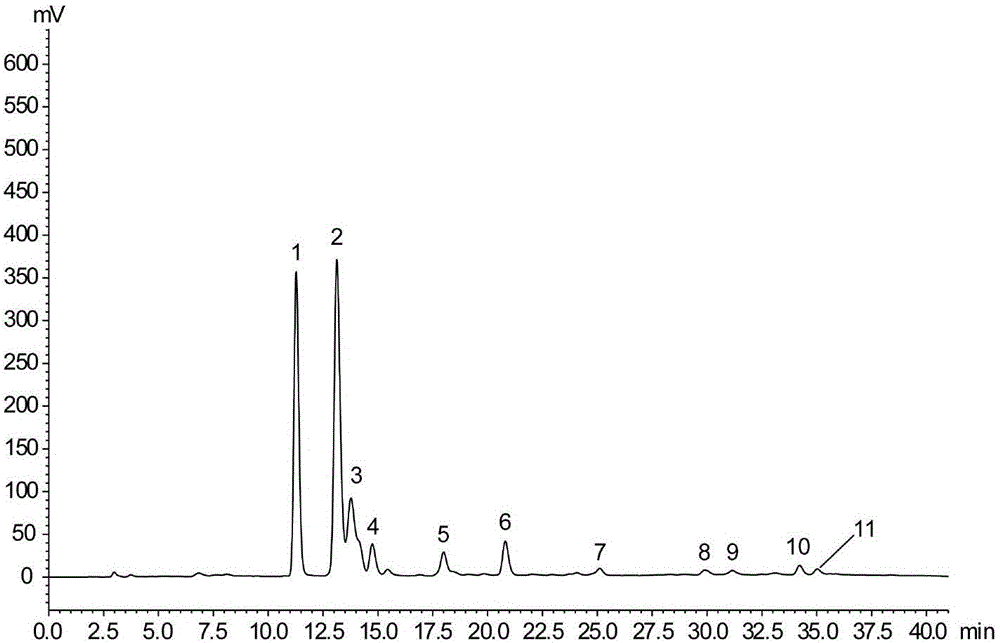

[0047] Catalytic synthesis of silibinin under the condition of sufficient amount of hydrogen peroxide in embodiment 3

[0048] In the present embodiment, hydrogen peroxide is equal to the amount of docetaxel, and the mol ratio of coniferyl alcohol and docetaxel is still 2:1, that is, coniferyl alcohol: docetaxel: H 2 o 2 =2:1:1.

[0049] Dilute 30% hydrogen peroxide to 12.23mM with PP Buffer (pH7.0). Dissolve horseradish peroxidase at 5000 U / mL in PP Buffer (pH 7.0). Other reagent concentration is identical with embodiment 1. The specific reaction system is shown in Table 3. The reaction times are: 2, 5, 10, 15, 20, 30, 45, 60 min. All reactions were carried out 3 times and the average value was taken.

[0050] Table 3 Reaction system under the condition of sufficient hydrogen peroxide

[0051]

[0052]

[0053] *MeOH is added after the reaction to terminate the enzymatic reaction.

[0054] The results show that when there is enough hydrogen peroxide to participa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com