Blending method capable of effectively improving quality of uniformly-mixed ores

A technology of mixing ore and quality, which is applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of large composition differences and composition differences of different mineral types, and achieve the effects of less investment, easy operation, and obvious quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

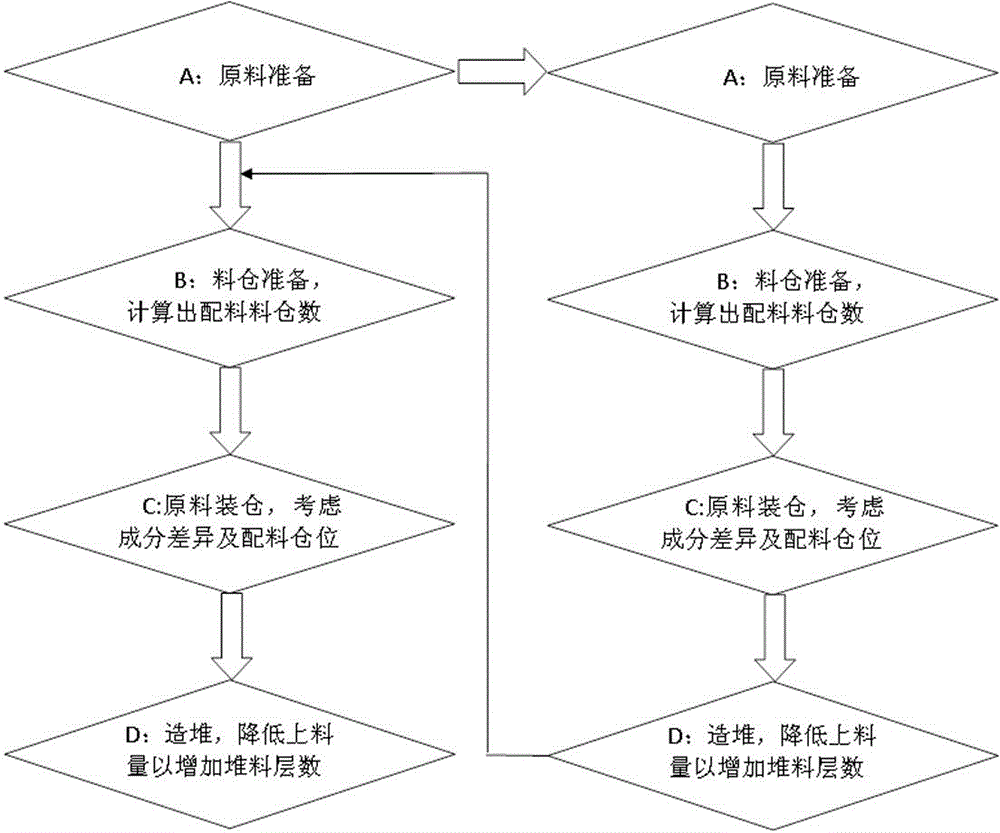

Method used

Image

Examples

Embodiment 1

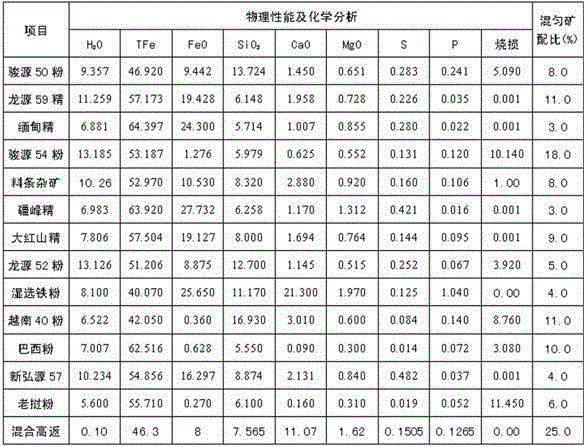

[0034] Taking 251# stockpiles as an example, the physical properties and chemical analysis of various minerals are shown in Table 1:

[0035] Table 1: 251# stockpile ratio

[0036]

[0037] A. Raw material preparation:

[0038] 1) According to Table 1, small minerals with a heaping ratio of about 5% or less: Burma fine, Jiangfeng fine, Longyuan 52 powder, wet iron powder, Xinhongyuan 57 powder, Lao powder and peripheral powder: Junyuan 50 powder, sliver miscellaneous ore, Longyuan 52 powder and Xinhongyuan 57 powder shall be pre-mixed within three days; , it can be concluded that the total amount of premixed stockpiles is 26800t; the total amount of new iron stock in 251# stockpiles is 72000t, and the above small and unstable minerals account for 41% of the total amount of new iron stockpiles, which is 29520t; When stacking, according to step C: the priority order of the difference in the composition of each batching mineral is: SiO 2 > TFe > Moisture > Particle Size, ca...

Embodiment 2

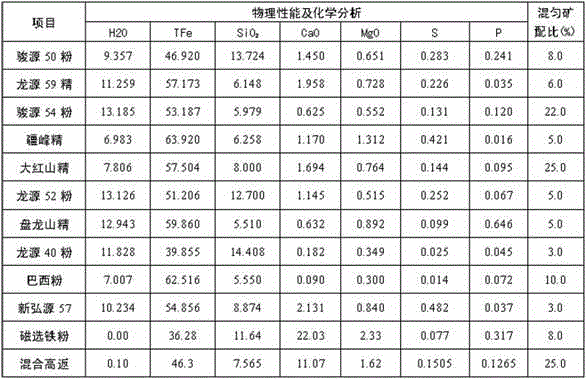

[0062] Taking 252# stockpiles as an example, the physical properties and chemical analysis of various minerals are shown in Table 8:

[0063] Table 8: 252# stockpile ratio

[0064]

[0065] A. Raw material preparation:

[0066] 1) According to Table 8, small minerals with a heaping ratio of about 5% or less: Longyuan 59 fine, Jiangfeng fine, Longyuan 52 fine, Panlongshan fine, Longyuan 40 fine, Xinhongyuan 57 fine and peripheral Mixing powder: Junyuan 50 powder, Longyuan 52 powder, Xinhongyuan 57 powder and unstable minerals: Magnetic separation iron powder pre-mixing and piling within three days; pre-mixing piling operation rate is 80%; #The total amount of new iron material in the pile is 72,000t, and the above small and unstable minerals account for 43% of the total amount of new iron material, which is 30,960t; when building a premixed pile, according to step C: the difference in the composition of each batching mineral The order of priority is: SiO 2 > TFe > Moistur...

Embodiment 3

[0090] Taking 253# stockpiles as an example, the physical properties and chemical analysis of various minerals are shown in Table 15:

[0091] Table 15: 253# stockpile ratio

[0092]

[0093] A. Raw material preparation:

[0094] 1) According to Table 15, small minerals with a heaping ratio of about 5% or less: Longyuan 51 powder, Junyuan 54 powder, Longyuan 50 powder, Jiangfeng Refining, oxidized slag, strip miscellaneous ore, magnetic iron separation Powder, mixed powder and unstable minerals: Junyuan 50 powder, Longyuan 50 powder, Longyuan 51 powder, strip miscellaneous ore, and magnetic separation iron powder are pre-mixed and mixed within three days; pre-mixed heap operation The total amount of new iron material in the 253# stockpile is 72,000t, and the above small and unstable minerals account for 57% of the total amount of new iron material, which is 41,040t; when building a premixed heap, follow Step C: each The priority order of the difference in the composition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com