An experimental system for simulating blast furnace bellless merging and distributing of tanks

An experimental system and material distribution system technology, which is applied in the field of simulated blast furnace bellless and tank material distribution experimental system, can solve the problems of inability to fully reflect the distribution of blast furnace charge surface, lack of flexibility in experiment and measurement, and inability to reflect the falling behavior of charge, so as to achieve saving Test materials and test charge, reduce test workload, and design flexibly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

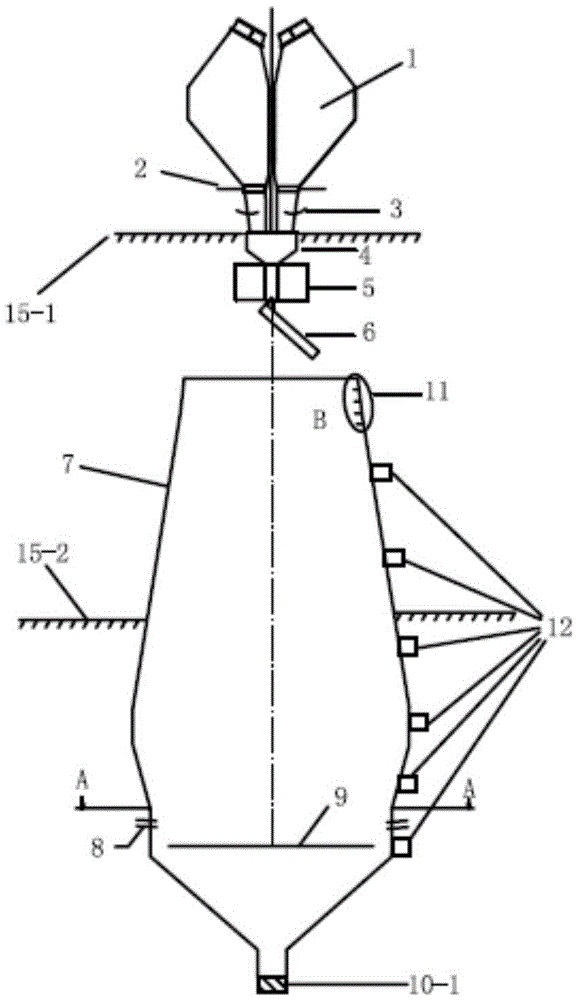

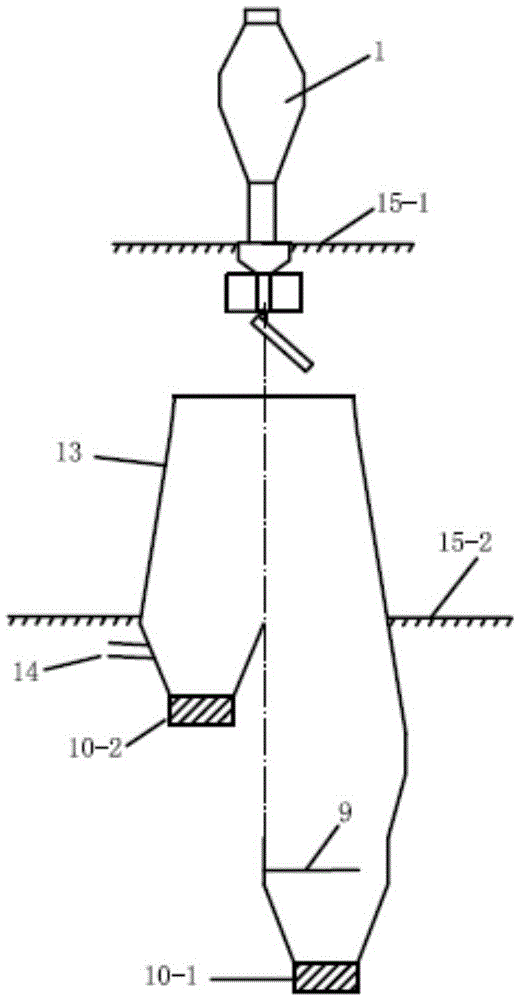

[0027] The material tank system is made of the actual blast furnace material tank, which keeps the same shape and size and is reduced according to a certain ratio. The two material tanks 1 are welded together with the manual discharge valve 2 below to form a unit, and the two units are fixed by steel beams. The manual discharge valve is composed of a valve body and a valve plate. The valve body and the material tank are welded together. The valve body is a circular steel plate, and the steel plate is connected with a handle. The gate valve can be opened and closed by turning the handle. When charging, the person stands on the second-floor platform 15-1 and rotates the handle counterclockwise, so that the flapper valve is closed to block the bottom of the tank; when discharging, the handle is rotated clockwise, so that the bottom of the tank is in an open state. The material flow regulating valve 3 is fixed together with the second-layer platform 15-1 by bolts. It has two work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com