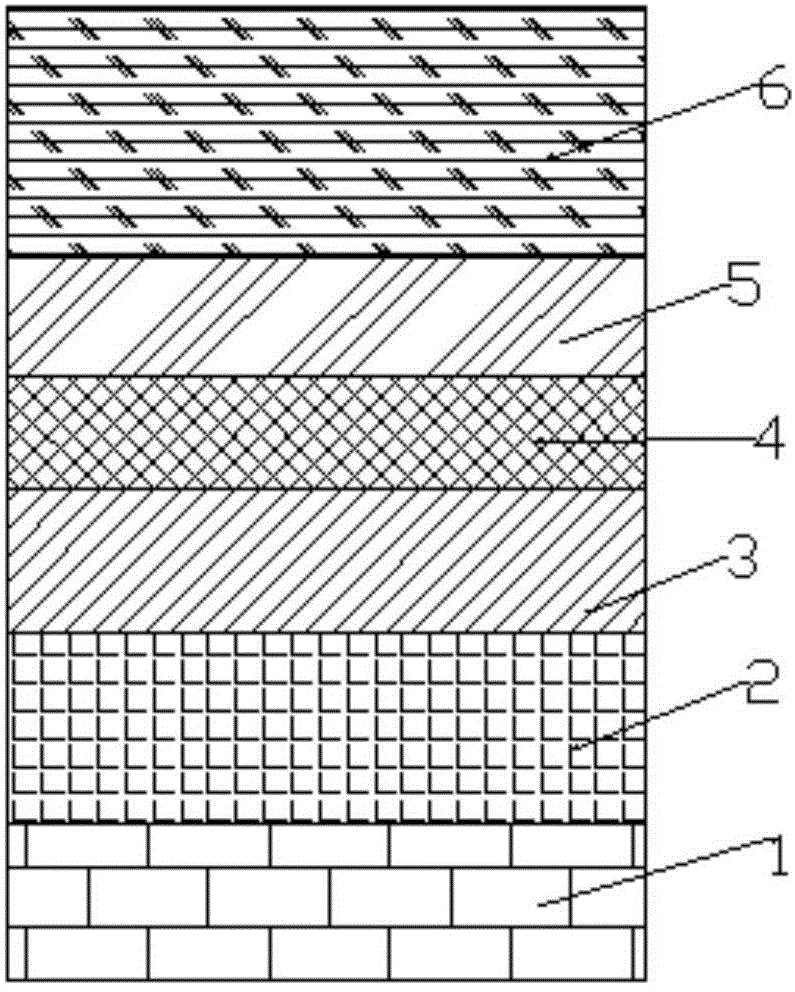

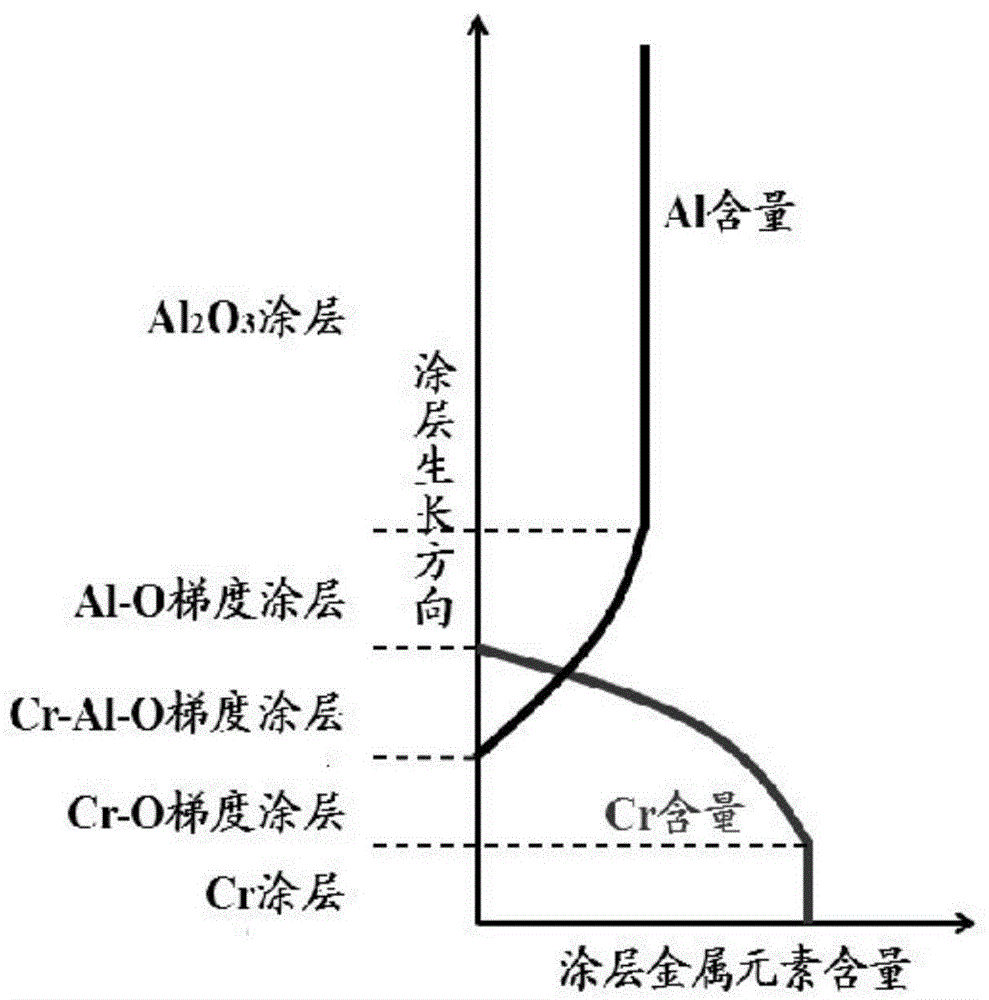

Double-component gradient hydrogen permeation barrier coating and preparation method thereof

A composition gradient, two-component technology, applied in the coating, metal material coating process, ion implantation plating, etc., can solve the problems of mechanical failure, reduction of coating hydrogen penetration resistance, weak interface damage, etc., and achieve residual stress Small size, good resistance to hydrogen permeation, and excellent thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A QX-500 commercial magnetron sputtering coating machine was used to prepare a two-component gradient (Cr, Al)O hydrogen permeable coating on the surface of 304 stainless steel substrates, including the following process steps:

[0030] Step (1), polishing and cleaning the surface of the steel substrate

[0031] The 304-type steel substrate is polished with 100 mesh to 2000 mesh water sandpaper and polishing flannelette in turn, and polished with a diamond polishing agent with a particle size of 3 μm, so that the surface of the steel substrate has a mirror effect. Then use degreasing agent to clean, pickle, deionize, rinse, and dry. The degreasing agent formula is composed of sodium carbonate 160g / L, sodium citrate 45g / L, active agent 5g / L, and sodium phosphate 50g / L; The steel substrate is placed in the vacuum chamber of the magnetron sputtering coating machine for plasma bias backsputter cleaning. The process parameters are: the background vacuum is 5×10 -4 pa, the b...

Embodiment 2

[0052] In this embodiment, a QX-500 type commercial magnetron sputtering coating machine is used to prepare a two-component gradient (Cr, Al)O hydrogen permeable coating on the surface of a 316 stainless steel substrate. Compared with Example 1, there are differences in the following process conditions:

[0053] The difference from step (2) in Example 1 is that the thickness of the Cr coating is 50nm.

[0054] Different from step (3) in Example 1, the vacuum chamber is gradually filled with O 2 The increasing rate of the gas is 10 sccm / min, and the thickness of the obtained Cr-O composition gradient coating is 20 nm.

[0055] Except for the above, other process parameters are the same. Adopt the same coating performance testing method as in Example 1. The results show that the interfacial adhesion between the two-component gradient (Cr, Al)O hydrogen-resistant permeable coating formed in this example and the No. 316 steel substrate is 35N; the residual compressive stress of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap