Control system of automatic diversified sewing machine

A control system and sewing machine technology, applied in the direction of sewing machine control devices, sewing machine components, sewing equipment, etc., can solve the problems of no port motor control, no motion control system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

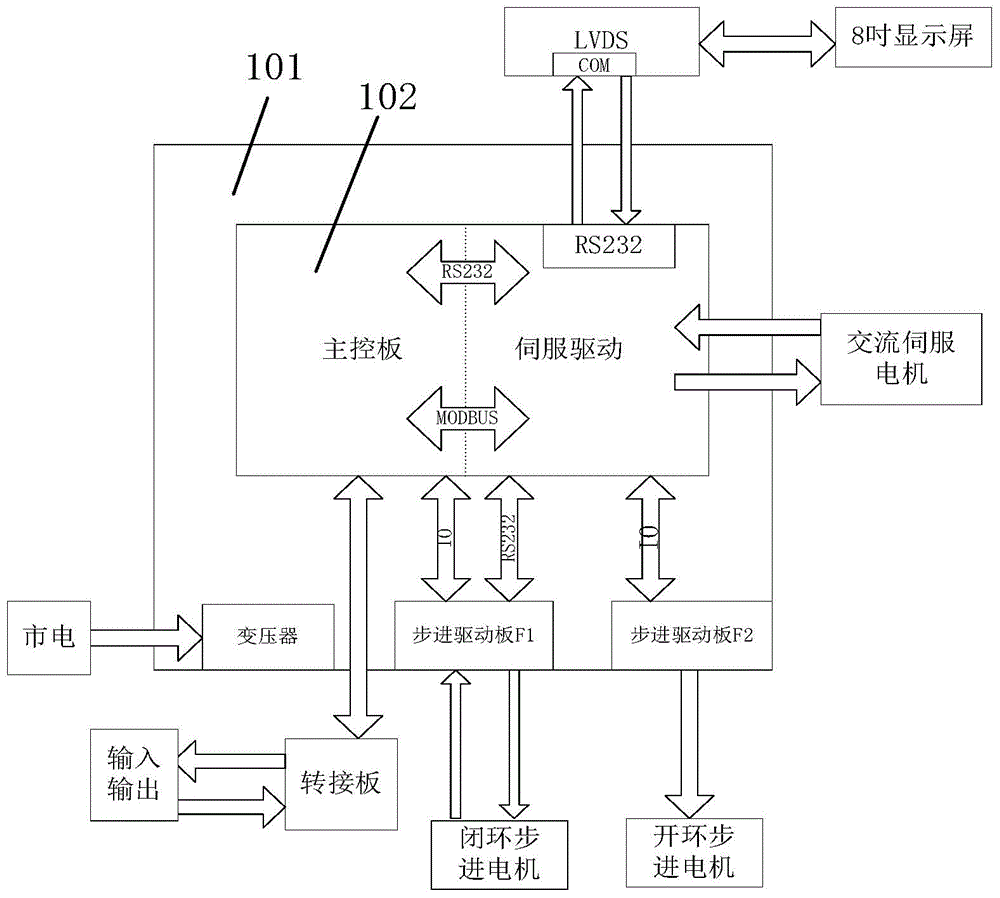

[0012] The present embodiment provides a kind of control system of fully automatic diversified sewing machine, such as figure 1 As shown, the control system includes a servo drive board and a main control board arranged on a main board 101, wherein the servo drive board and the main control board are integrated on a circuit board 102, and the servo drive board and the main control board pass through the circuit board In this way, compared with the servo drive board and the main control board, which are set separately and connected through ports, the integrated servo drive board and the main control board can realize the short-distance connection between the servo drive and the control, reduce the line ports, and thus can Reduce line interference, reduce costs, and improve communication efficiency.

[0013] Moreover, a closed-loop step driver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com