Composite pile structure serving as main structure stand column and construction method thereof

A technology of main structure and composite pile, which is applied in foundation structure engineering, sheet pile wall, building, etc. It can solve the problems that the retaining wall mud will pollute the surrounding environment, the quality of the pile body is not easy to guarantee, and honeycombs and cavities are easy to appear, so as to achieve the bearing capacity Large, improved ability to resist horizontal loads, and reliable connection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

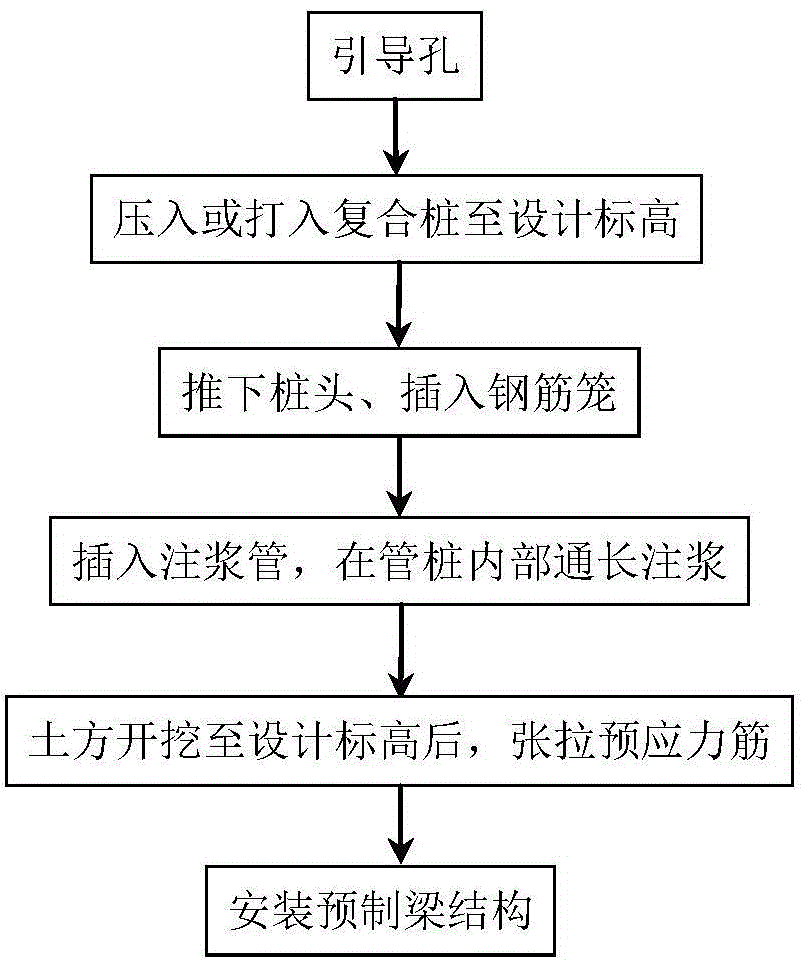

[0056] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

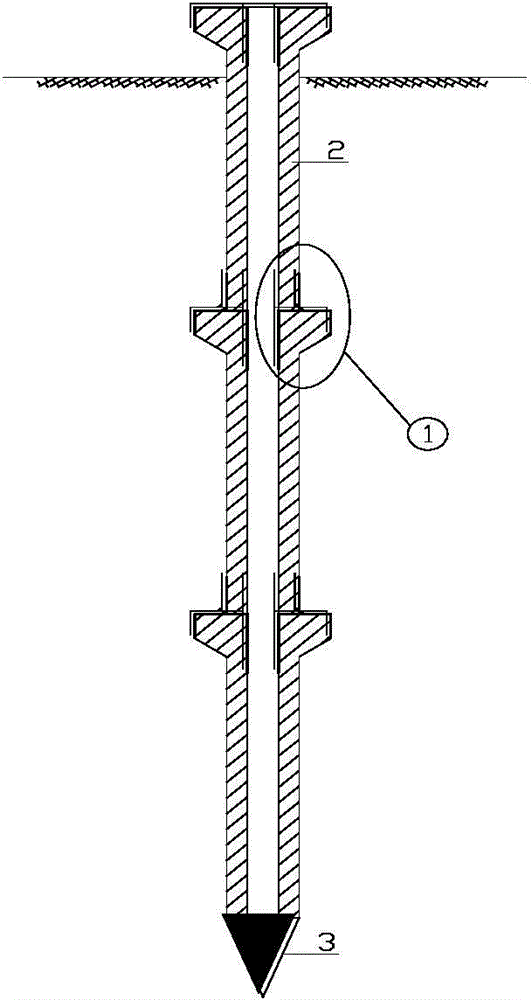

[0057] Such as Figure 2(a)-Figure 2(f) , Figure 3-Figure 14 As shown, the composite pile structure as the column of the main structure includes the segmental prefabricated pile 2 with corbels. The inner wall of the segmental precast pile 2 with corbels is provided with irregular protrusions. The shape is square on the outside and circular on the inside, the pile bottom of the segmented prefabricated pile 2 with corbels has a pile head 3, the pile top of the segmented prefabricated pile 2 with corbels has a corbel 2-1, and the pile top of the segmented precast pile 2 with corbels has a corbel 2-1, The center of the segmental prefabricated pile 2 is provided with a through hole, the through hole is provided with a steel cage 4, the through hole of the segmental prefabricated pile 2 with corbels is filled with grouting material 5, and the segmental pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com