Three-direction-adjustable combined rod type inner supporting tool and construction method and application thereof

A combined rod and adjustable technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of low reuse rate, affecting the quality of walls, and large material consumption, etc. Achieve the effect of simple construction method, improve project quality and reduce labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

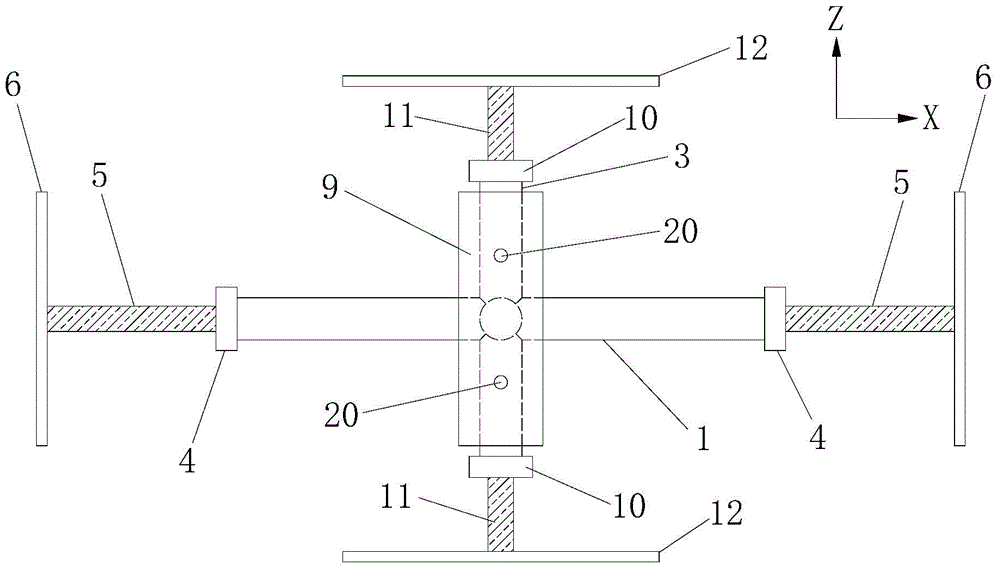

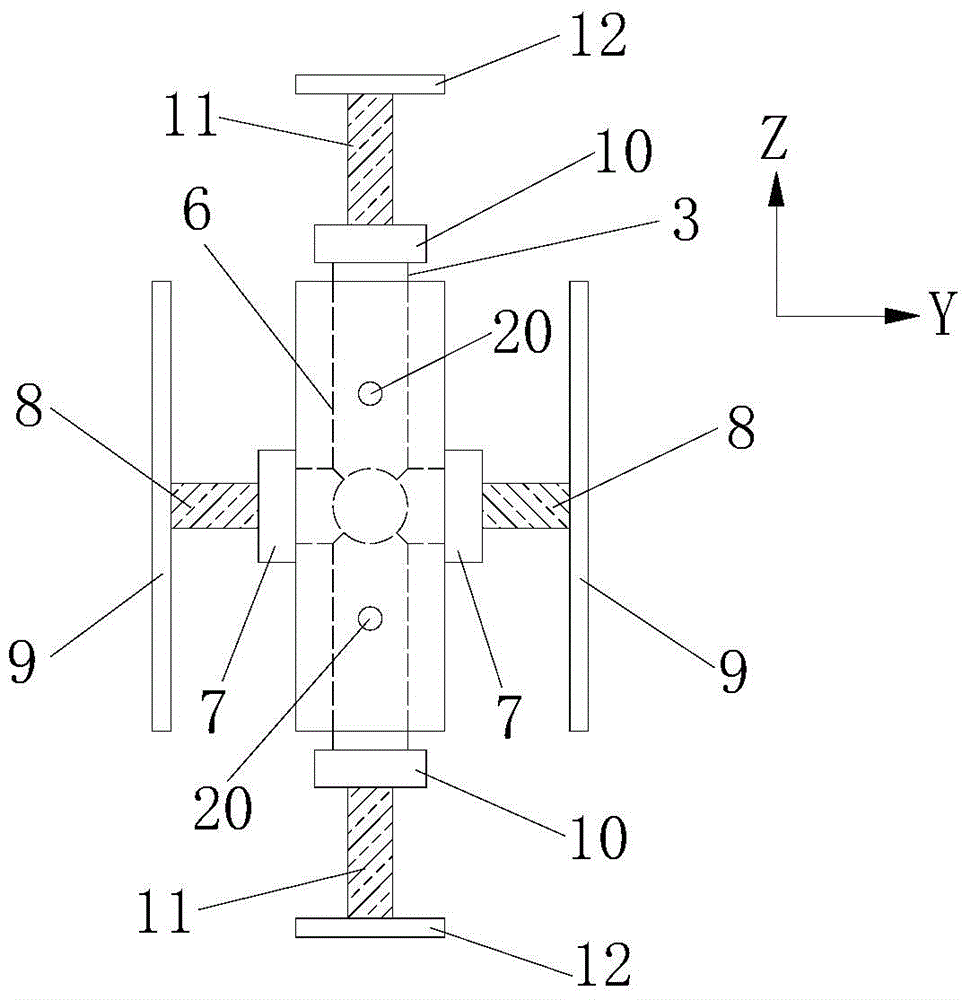

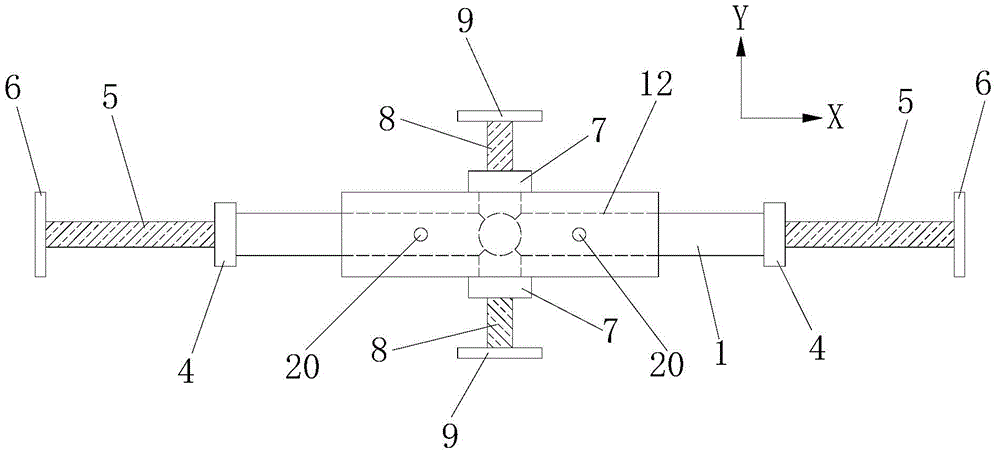

[0051] Such as figure 1 , figure 2 with image 3 As shown, the three-way adjustable combined rod type internal support tool of the present invention includes an X-direction sleeve 1 arranged along the X-axis direction, a Y-direction sleeve 2 arranged along the Y-axis direction, and a Z-direction sleeve arranged along the Z-axis direction. Sleeve 3, the middle part of the X-direction sleeve 1, the middle part of the Y-direction sleeve 2 and the middle part of the Z-direction sleeve 3 are fixedly connected together; both ends of the X-direction sleeve 1 are fixedly connected with X-direction Nut buckle 4, the two X-direction nut buckles 4 are threaded with X-direction screw 5 inserted into the X-direction sleeve 1, and the two X-direction screw 5 are exposed on the X-direction sleeve 1 One end of the outer end is fixedly connected with an X-direction support plate 6; both ends of the Y-direction sleeve 2 are fixedly connected with a Y-direction nut buckle 7, and the two Y-dir...

Embodiment 2

[0067]The three-way adjustable combined rod-type internal support tool in this embodiment is different from that in Embodiment 1 in that: the X-direction sleeve 1, the Y-direction sleeve 2 and the Z-direction sleeve 3 are all made of DN20 national standard galvanized steel pipe , the length of the X-direction sleeve 1 is 420mm, the length of the Y-direction sleeve 2 is 100mm, and the length of the Z-direction sleeve 3 is 270mm; the X-direction screw 5, the Y-direction screw 8 and the Z-direction screw 11 are trapezoidal screw with a nominal diameter of 14mm, the length of the X-direction screw 5 is 210mm, the length of the Y-direction screw 8 is 50mm, and the length of the Z-direction screw 11 135mm; the X-direction support plate 6, the Y-direction support plate 9 and the Z-direction support plate 12 are all made of steel plates with a thickness of 5mm, the X-direction nut buckle 4, the Y-direction nut buckle 7 and the Z-direction The lengths of the screw holes of the nut buck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com