A front-end steam turbine generator room combined with a side coal bunker and arranged at a high level

A technology of turbo generators and side coal bunkers, which is applied in the direction of machines/engines, mechanical equipment, steam engine devices, etc., and can solve problems such as cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

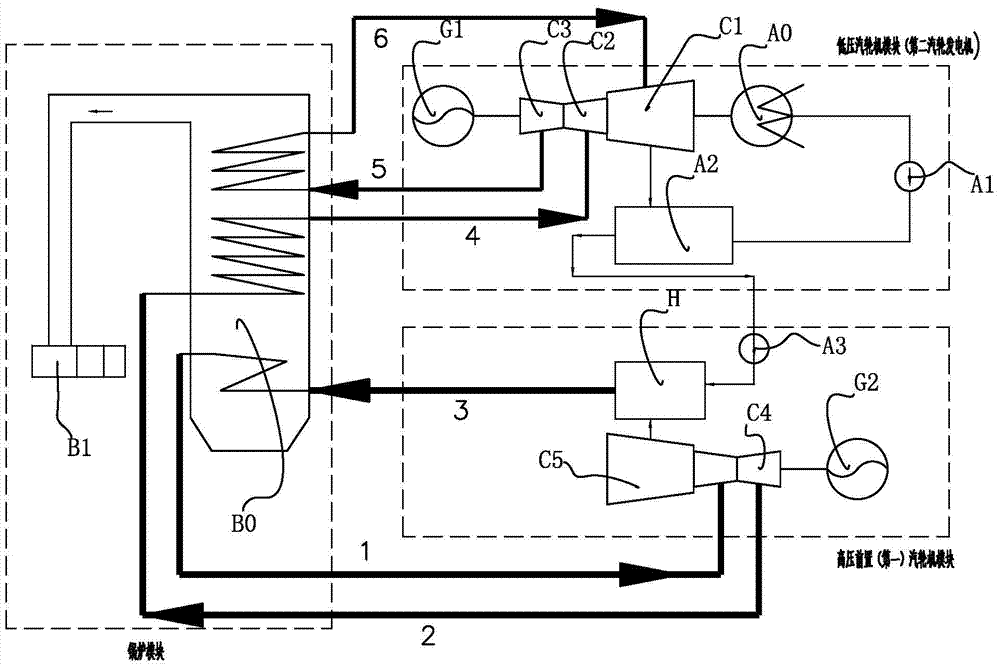

Method used

Image

Examples

Embodiment 1

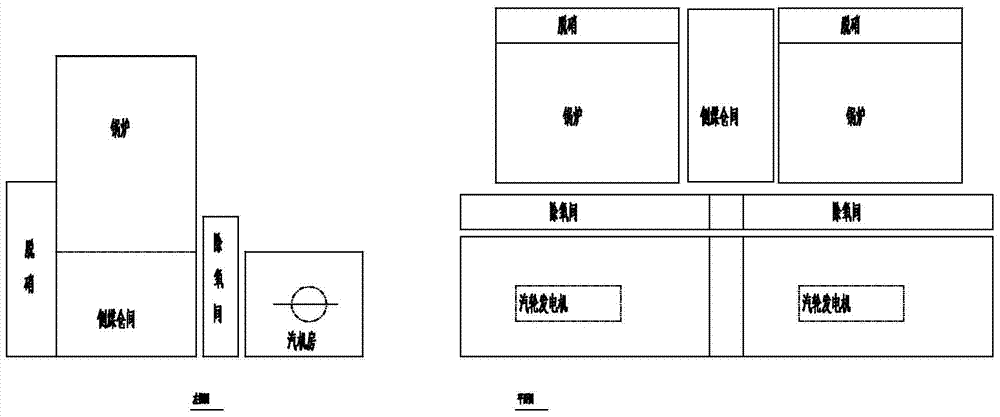

[0073] image 3 It is a structural diagram of the side coal bunker combined with a high-position front turbine generator house in embodiment 1 of the present invention.

[0074] versus figure 2 Compared with the main plant of the steam turbine generator shown, the present invention arranges the front machine room of a single unit on the side coal bunker room through the side bunker frame.

[0075] The side coal bunker combined with the high-position front turbine generator house structure of the present invention includes: 2 boilers, a side coal bunker room located in the middle of the boiler, 2 deaeration rooms, a first steam turbine generator, and a second steam turbine for power generation A deaeration room is provided on the adjacent side of the proximal end of the side coal bunker, and a steam engine room is provided on the adjacent side of the deaeration room, and a second steam engine room is provided in the steam engine room. Turbo-generator, the second turbo-generator is ...

Embodiment 2

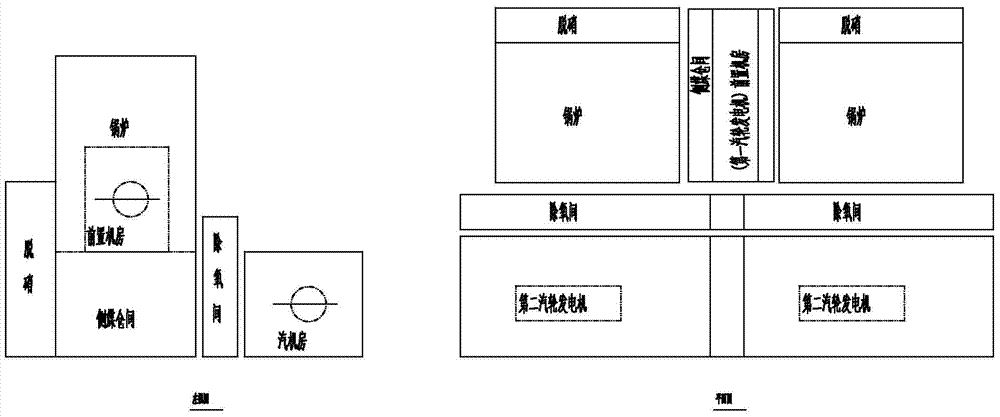

[0082] Figure 4 It is a structural diagram of the side coal bunker combined with a high-position front turbine generator house in Embodiment 2 of the present invention.

[0083] The second embodiment of the present invention is similar to the first embodiment, but the difference lies in that the front machine rooms of the two first steam turbine generators are combined and arranged above the side coal bunker located between the two boilers. The volume of the front machine room of the double unit is 72000m 3 .

[0084] The high-position front turbine generator room of this embodiment 2 can reduce the main steam pipeline site by 50%-60%, and the relative length of the main steam pipeline can reach 3 / 10, and the absolute length is ≤40m. The length of the connecting piping system can be shortened to 60m, which can save the cost of the main steam pipeline by 45%, reduce the overall cost by 18%, and increase the pipeline efficiency by more than 58%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com