Double-layer steel pipe expansion type pipe external casing packer

An expansion type, packer technology, applied in the directions of sealing/packing, wellbore/well components, earth-moving drilling, etc., can solve the problems of difficult to pack complex strata, easy pack failure, short pack time, etc. Achieve the effect of providing formation isolation capability, improving isolation effect, and long isolation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

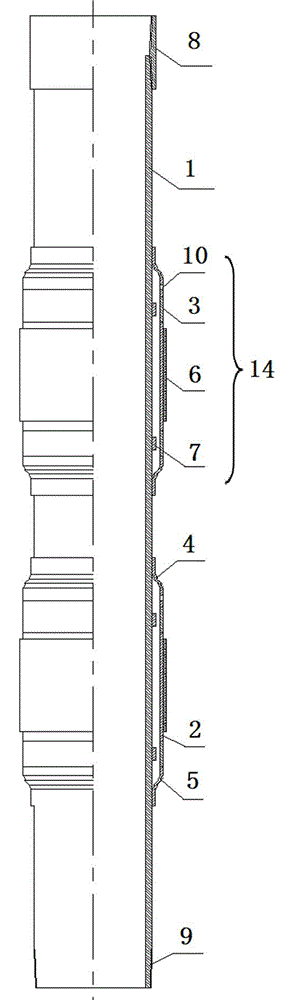

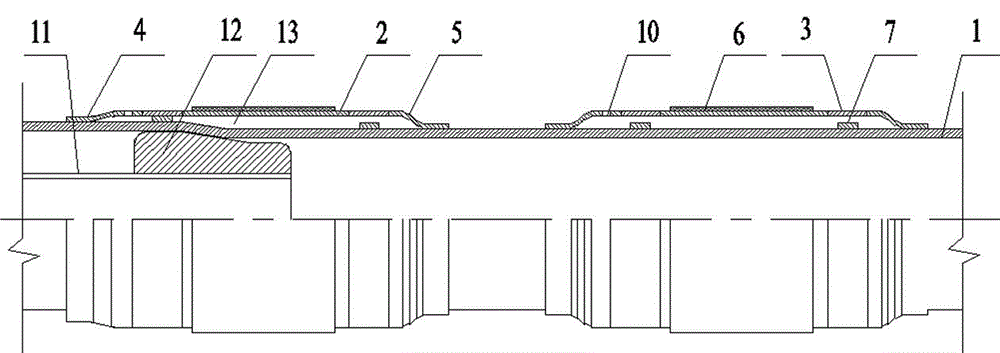

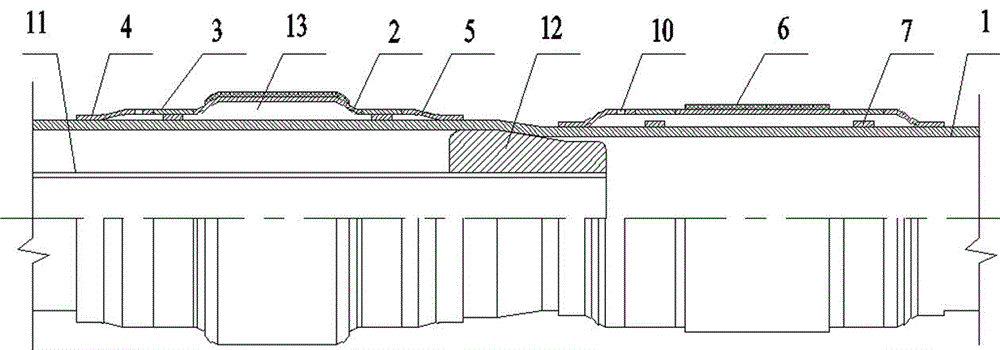

[0024] Now in conjunction with the accompanying drawings of the description, the present invention will be further described.

[0025] Such as Figure 1~3 As shown, a double-layer steel pipe expandable external packer is composed of an expandable base pipe 1, a packing unit 14, an upper joint 8 and a lower joint 9, and the two ends of the expandable base pipe 1 are processed with upper joints 8 and The lower joint 9 and the packing unit 14 are mainly composed of the expansion outer tube 2, the connecting nipple 3, the upper fixing nipple 4, the lower fixing nipple 5, the rubber tube 6, the seal 7, the liquid inlet hole 10 and the expansion chamber 13, etc. . Both the expansion base pipe 1 and the expansion outer pipe 2 are made of expandable steel pipe material, and the expansion outer pipe 2 is thinner than the expansion base pipe 1, so it is easier to realize hydraulic expansion, and its shape can be a round pipe or a corrugated round pipe Isotropic tubes. The expansion o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com