Snake-shaped spring

A serpentine spring, serpentine technology, applied in springs, springs/shock absorbers, leaf springs, etc., can solve problems such as restricting vehicle ride comfort and operating stability, large unsprung mass, etc., to ensure reliability, reduce The effect of overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

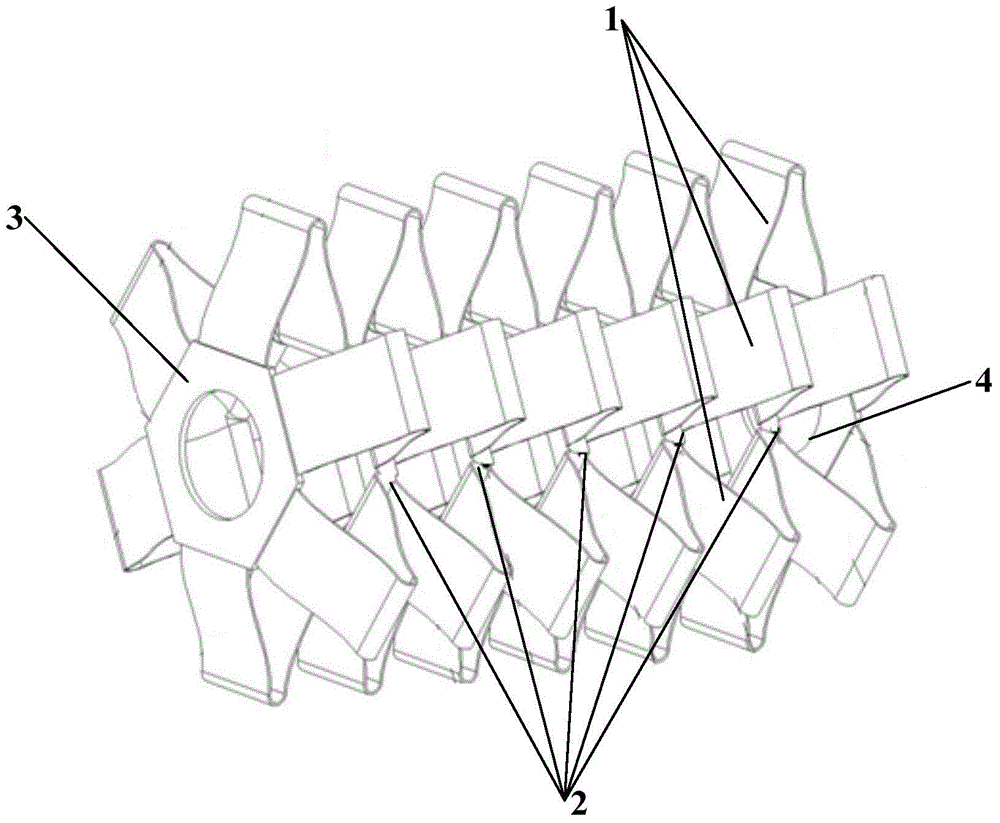

[0027] Such as figure 1 As shown, the embodiment of the present invention provides a serpentine spring, including: a plurality of spring units 1 , a stabilizing ring 2 , a first support seat 3 and a second support seat 4 .

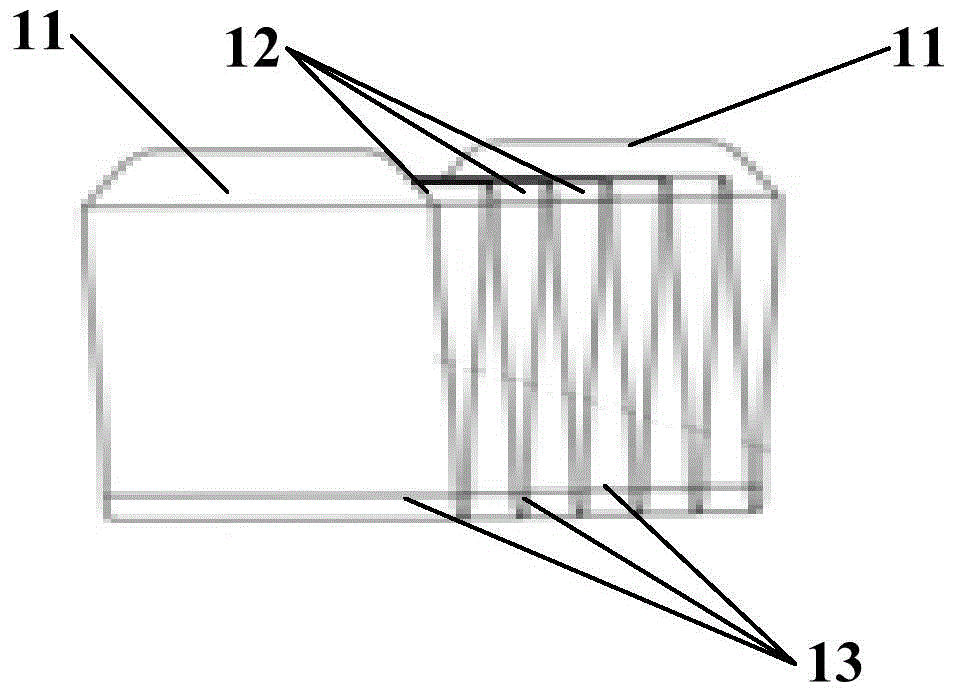

[0028] The spring monomer 1 adopts a serpentine bending sheet structure, which realizes the stretchable mechanical properties of the spring. The sheet structure reduces the mass of the spring monomer 1 to a certain extent, thereby The mass of the serpentine spring is reduced.

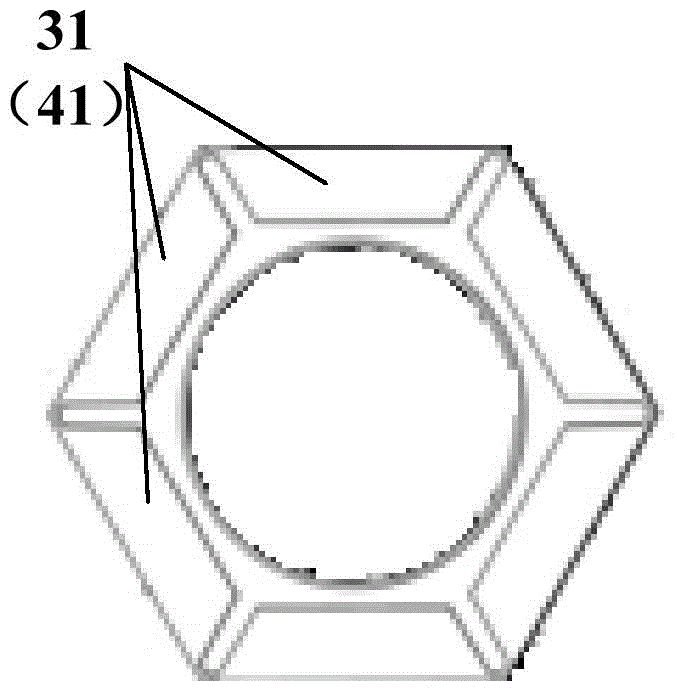

[0029] The stabilizing rings 2 are polygonal annular structures, and each stabilizing ring 2 is sleeved on the bending part of the spring unit 1, and the spring unit 1 and the stabilizing ring 2 cooperate to form an external spline structure. Wherein, the number of spring monomers 1 is equal to the number of sides of the stabilizing ring 2, for example, if the number of spring monomers 1 is four, then the stabilizing ring 2 is a quadrilateral.

[0030] The first support seat 3 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com