Regional cooling and heating system

A heating system and area technology, applied in heating systems, district heating systems, heating and ventilation control systems, etc., can solve the problems of inability to supply energy in large areas and low energy supply efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

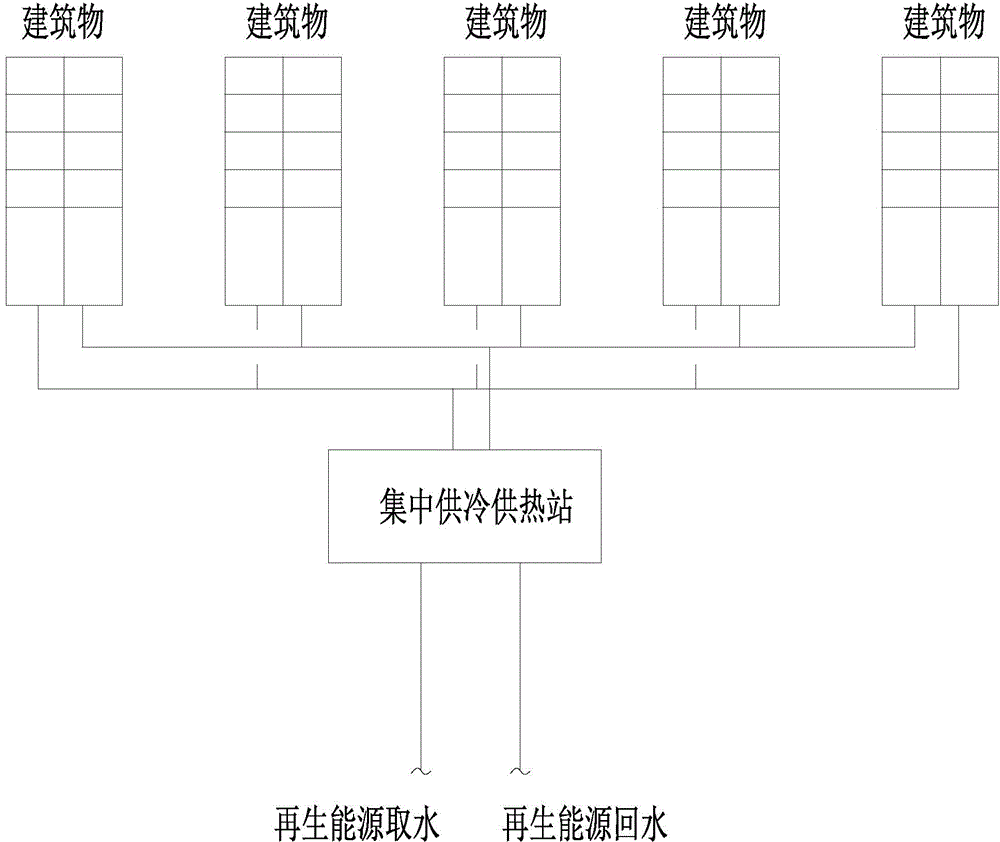

[0037] Such as Figure 4 , a district cooling and heating system, including a central cooling and heating main station 1, several cooling and heating sub-stations 2 connected to the central cooling and heating main station for cooling and heating of buildings, in order to be more To obtain heat from renewable energy sources, the centralized cooling and heating station will be built near the renewable energy sources, which can be set up in the traditional way;

[0038]A total bypass circulation pipe 5 is connected between the total outlet pipe 3 and the total return pipe 4 of the centralized cooling and heating station, and a total control valve 10 for controlling the circulation of the medium is arranged on the total bypass circulation pipe, and The detector used to detect the temperature of the medium in the total outlet pipe and the total return pipe, the detector sends the detected temperature to a controller, and the controller compares the received temperature signal with...

Embodiment 2

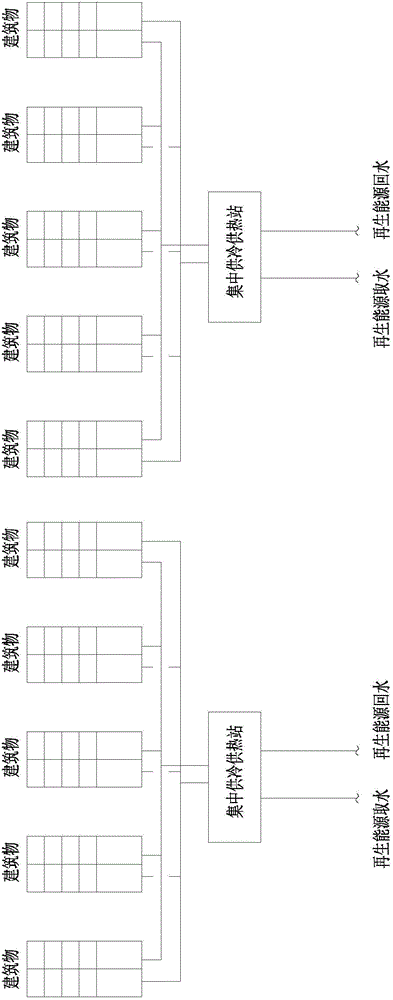

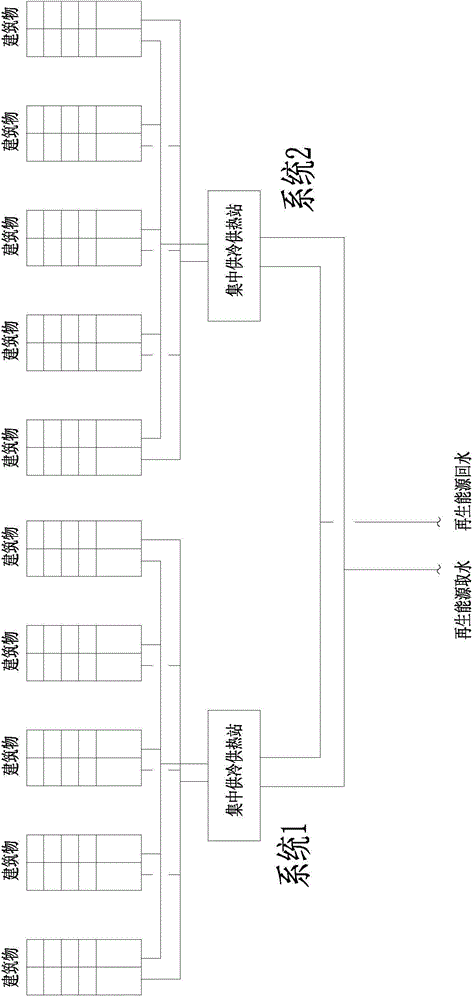

[0042] see Figure 5 , each cooling and heating sub-station can be connected in series; this avoids the defect that the heating station needs to be placed in the middle of multiple buildings in the existing traditional method, that is, the cost of the pipeline is reduced, The second is to reduce the loss of heat energy in the pipeline.

Embodiment 3

[0044] see Figure 6 , 7 , in order to improve the thermal energy efficiency of the cooling and heating sub-station 2 and reasonably recycle heat, the cooling and heating sub-station includes the first sub-heat pump unit 10, the second sub-heat pump unit 11, the second sub-heat pump unit 12, three sub-stations The heat pump units all have an input end 13 and a return end 14. The input ends of the first sub-heat pump unit, the second sub-heat pump unit, and the third sub-heat pump unit are respectively connected to the heat supply inlet pipe 6. The first sub-heat pump unit, the second sub-heat pump unit The return ends of the heat pump unit and the third sub-heat pump unit are respectively connected to the heat supply return pipe 7; in this way, the liquid medium in the central cooling and heating station can enter the three sub-heat pump units respectively through the heat supply inlet pipe for heat exchange. The final liquid medium then passes through the heat supply return ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com