Sensible heat storage type cavity concentrating and absorbing heat solar heat collection device and method

A solar heat collector and heat storage technology, which is applied in solar thermal devices, solar heat collectors, solar heat collectors using working fluids, etc., can solve the problem of long heat transfer loops, low overall system efficiency, resistance and heat loss and other problems, to achieve the effect of improving utilization rate, compact structure, and solving discontinuous irradiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

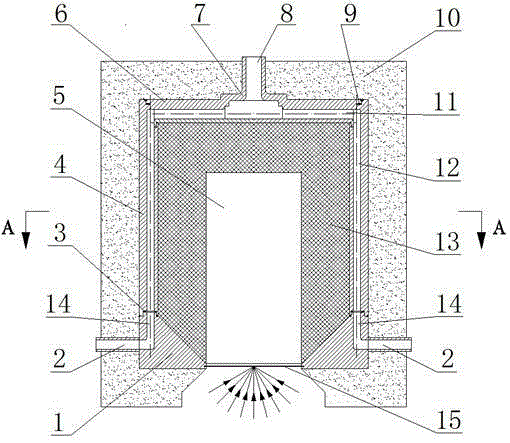

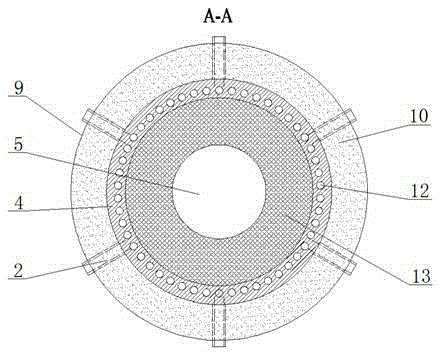

[0027] Such as Figure 1-5 As shown, the sensible heat storage cavity concentrating and heat absorbing solar heat collection device includes an inlet annular shunt cavity 1, a first sealing gasket 3, a sleeve heat exchanger 4, a heat absorption cavity 5, an outlet confluence cavity 6, a second Two sealing gaskets 9, insulation layer 10, heat storage body 13) lens 15;

[0028] The body of the heat collecting device is provided with a heat absorbing chamber 5, a heat accumulator 13, and a sleeve heat exchanger 4 sequentially from the inside to the outside, and a lens 15 is installed at the mouth of the heat absorbing chamber 5; The inner wall of the cylindrical heat exchanger 4 is closely attached;

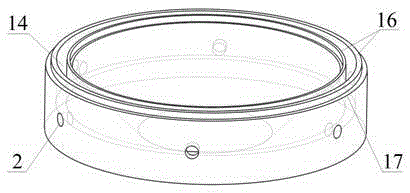

[0029] The inlet annular distribution chamber 1 includes the cold fluid inlet flow channel 2, the inlet annular distribution chamber flow channel 14, the inlet annular distribution chamber sealing groove 16, and the inlet annular distribution chamber upper edge 17;

[0030] A plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com